Monolithic Refractories for Iron and Steel Industry - Ladle Shroud Long Nozzle Chinese Steelmaking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Steelmaking long nozzle /refractory materials/refractory nozzles

steelmaking zircon nozzle Zr content 94-95% , and nozzle with metal shell ,

can protect nozzle burst.the casting temperature normally at 1520-1580 ℃.

our zirconia cores temperature resistance up to 2000℃, density is 4.2g/cm3 .

Steelmaking tundish nozzle zircon core contact face made a little big than other,effectively protect the nozzle using life.

tundish zirconia nozzles materials is alumina-zirconia-carbon .composed by Alumina-Carbon Shell, and zirconia core.

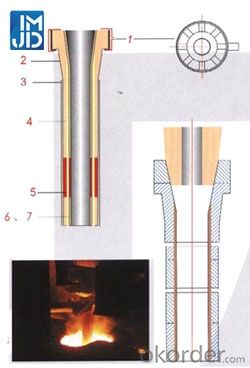

Graphic illustration:

1.Argon injection structure depending on customer specifications.

2.Ceramic glaze layer to prevent the material oxidation effectively.

3.Ceramic fiber blanket to prevent heat lost during casting.

4.High quality Al-C materials having high corrosion and thermal shock resistance.

5.High quality Zr-based composite to provide high corrosion resistance at the slag line.

6.Non-graphite based mased materials to meet the requirements of producing low carbon steel,silicon steel and high purity steel.

Manufacturing and QC

1.Raw materials blending

Independent raw materials blending center to assurestrict control of materials quality.

2.Shaping

Isostatic pressing technoloty,with as 1000 tons of pressure to assure the homogenous bulk density of each product.

3.Machining

To assure the uniform shape,dimension and dimension tolerance of each product.

4.X-ray defect inspection

To assure all products supplied to our customers without any defect and to prevent the un-countable feconomic loss for our customers.

5.Physical and chemistry analysis

To assure all products meet the physical and chemistry characteristics.

6.Packaging

The world-class for packaging to assure the safety transportation.

- Q: How do monolithic refractories impact the quality of iron and steel products?

- The quality of iron and steel products is greatly influenced by monolithic refractories. These refractories are extensively used in the lining of furnaces and other high-temperature environments where iron and steel undergo processing. To begin with, monolithic refractories play a vital role in insulating and safeguarding the furnace lining from the intense heat generated during the manufacturing of iron and steel. By maintaining the desired temperature, these refractories ensure consistent and proper heating of the metal, thereby achieving the desired product quality. Inadequate insulation would result in significant heat loss, leading to inefficient energy consumption and inconsistent product quality. Additionally, monolithic refractories have a significant impact on the overall cleanliness of iron and steel. During the production process, impurities and slag are formed, which can contaminate the metal if not managed properly. Refractories with high resistance to slag penetration and corrosion prevent these impurities from infiltrating the metal, ensuring a cleaner and purer final product. Moreover, monolithic refractories also contribute to the mechanical strength and durability of the furnace lining. The lining must withstand the harsh conditions and repeated thermal shocks encountered during the production process of iron and steel. A sturdy and well-designed refractory lining can resist cracking, spalling, and erosion, thereby prolonging the furnace's lifespan and reducing the risk of downtime. In conclusion, monolithic refractories have a profound impact on the quality of iron and steel products. They provide thermal insulation, prevent contamination, and ensure the mechanical integrity of the furnace lining. Manufacturers can optimize their production processes, enhance product quality, and improve overall operational efficiency by selecting the appropriate refractory material and maintaining it correctly.

- Q: How are monolithic refractories inspected and tested for quality assurance?

- Monolithic refractories are inspected and tested for quality assurance through various methods. Visual inspections are conducted to check for any visible defects such as cracks, spalling, or other physical damages. In addition, non-destructive testing techniques like ultrasonic testing and X-ray inspection are used to detect any internal flaws or inconsistencies in the refractory material. Furthermore, mechanical testing such as compression and flexural strength tests are performed to evaluate the mechanical properties of the monolithic refractories. These inspections and tests ensure that the refractories meet the required quality standards and can withstand the harsh operating conditions they are designed for.

- Q: How do monolithic refractories withstand the corrosive environments in steelmaking processes?

- Monolithic refractories withstand corrosive environments in steelmaking processes due to their high chemical resistance and thermal stability. These refractories are made from a single, continuous material, eliminating joints and weak points that can be susceptible to corrosion. They are composed of materials such as high-alumina, silica, or magnesia, which possess excellent resistance to chemical attacks from molten metals, slags, and gases present in steelmaking. Additionally, monolithic refractories can be designed with specific additives and binders to further enhance their resistance to corrosion, ensuring their durability and prolonged service life in the harsh conditions of steelmaking processes.

- Q: How are monolithic refractories repaired or replaced in iron and steel facilities?

- Monolithic refractories in iron and steel facilities are repaired or replaced through a process known as hot repair or hot gunning. This involves using specialized equipment to heat the damaged refractory material and remove it. The area is then prepared for new refractory installation, which is done by either shotcreting or gunning the new material onto the surface. This method allows for quick repairs and replacements, minimizing downtime and ensuring the efficiency and safety of the facility.

- Q: How do monolithic refractories improve the quality and consistency of iron and steel products?

- Monolithic refractories play a crucial role in improving the quality and consistency of iron and steel products. These refractories are unshaped and can be easily molded and installed, providing several advantages over traditional brick refractories. Firstly, monolithic refractories offer better thermal insulation properties, ensuring effective heat management during the production process. By maintaining consistent and controlled temperatures, these refractories prevent thermal shocks and minimize thermal gradients, leading to reduced cracking and distortion in the final products. This results in improved dimensional stability and overall better quality. Furthermore, monolithic refractories have excellent resistance to thermal spalling and erosion. They can withstand high temperatures, chemical attacks, and mechanical stress, protecting the lining of the furnaces and vessels used in iron and steel production. This resistance enhances the durability and reliability of refractory linings, preventing premature failure and extending the lifespan of the equipment. Another advantage of monolithic refractories is their ability to provide a seamless lining. Unlike brick refractories, which have joints and gaps that can lead to heat loss and uneven distribution, monolithic refractories create a continuous lining with no weak points. This ensures uniform heat distribution and minimizes the risk of hotspots or cold spots, resulting in consistent and reliable iron and steel products. Monolithic refractories also offer flexibility in design and installation. They can be customized to fit various shapes and sizes, allowing for better furnace design optimization. This flexibility enables efficient use of space, improved heat transfer, and reduced energy consumption, all of which contribute to the overall quality and consistency of the final iron and steel products. In summary, monolithic refractories improve the quality and consistency of iron and steel products by providing superior thermal insulation, resistance to thermal spalling and erosion, seamless linings, and flexibility in design and installation. These refractories enhance the efficiency and reliability of the production process, resulting in higher-quality final products that meet the industry's stringent standards.

- Q: What are the cost implications of using monolithic refractories in the iron and steel industry?

- The use of monolithic refractories in the iron and steel industry can have various cost implications. Firstly, the initial cost of monolithic refractories tends to be higher compared to traditional brick refractories. Monolithic refractories are typically made from high-quality raw materials and require specialized installation techniques, leading to higher upfront expenses. However, these higher upfront costs can be offset by the benefits provided by monolithic refractories in terms of performance, durability, and reduced maintenance requirements. One of the major cost implications of using monolithic refractories is their extended service life. Monolithic refractories have excellent thermal shock resistance and can withstand high temperatures, mechanical stress, and corrosive environments. This results in reduced downtime and fewer replacement or repair needs, leading to overall cost savings in the long run. Additionally, monolithic refractories offer flexibility in design and application. They can be easily shaped and installed to fit complex geometries, resulting in optimized furnace linings and improved energy efficiency. By minimizing heat loss, monolithic refractories can reduce fuel consumption and lower energy costs for the iron and steel industry. Furthermore, the installation and maintenance of monolithic refractories can be less labor-intensive compared to brick refractories. This can result in reduced labor costs and shorter installation time, leading to potential cost savings for the industry. Another cost implication of using monolithic refractories is their impact on productivity. Monolithic refractories provide improved thermal insulation, reduced slag adhesion, and enhanced resistance to wear and erosion. These properties can lead to increased production rates, improved product quality, and minimized process interruptions, ultimately translating into higher profitability for iron and steel manufacturers. It is important to note that the cost implications of using monolithic refractories can vary depending on the specific application, furnace type, and operating conditions. Therefore, a thorough cost-benefit analysis should be conducted to evaluate the overall economic impact of implementing monolithic refractories in the iron and steel industry.

- Q: What are the key properties of patching mixes used for monolithic refractory repairs?

- The key properties required for patching mixes used in the repair of monolithic refractories include: 1. High temperature resistance: The patching mixes should have the ability to withstand high temperatures without compromising their structural integrity. They must be capable of enduring temperatures ranging from 2000 to 3000 degrees Fahrenheit. 2. Chemical resistance: These patching mixes should be resistant to chemical reactions that occur in the presence of molten metals, slag, or other corrosive substances. They should not deteriorate or react with these materials, ensuring the longevity of the repaired refractory. 3. Thermal shock resistance: The patching mixes must have the ability to withstand sudden and extreme temperature changes without cracking or spalling. Refractory linings are often subjected to intense thermal cycling, and the patching material should be able to endure these conditions without failure. 4. Adhesion: The patching mixes should possess excellent adhesion properties to create a strong bond with the existing refractory material. This is crucial to prevent any separation or detachment of the patching material, which could result in further damage or failure. 5. Workability: The patching mixes should have good workability, allowing for easy and efficient application. They should be easily moldable and capable of effectively filling cracks, gaps, or damaged areas. 6. Setting and curing time: The patching mixes should have a reasonable setting and curing time. They should be able to harden quickly to minimize downtime during repairs, while also providing sufficient time for proper application and shaping. 7. Density and porosity: The patching material should have an appropriate density and porosity to resist penetration by molten metal or slag. Low porosity ensures that the repaired refractory maintains its thermal insulation properties. 8. Mechanical strength: The patching mixes should exhibit adequate mechanical strength to withstand physical stresses, such as abrasion or impact, that may occur during operation. 9. Compatibility: It is important that the patching mixes are compatible with the existing refractory material to ensure a seamless integration and prevent any potential chemical reactions or incompatibilities that could compromise the repair. By considering these key properties, patching mixes used for monolithic refractory repairs can effectively restore the integrity and performance of refractory linings, prolonging their lifespan and ensuring efficient and safe operation in high-temperature environments.

- Q: What are the typical applications of monolithic refractories in blast furnaces?

- Monolithic refractories are widely used in blast furnaces due to their unique properties and applications. These refractories are composed of a single, homogeneous material that can be shaped and installed in various forms without the need for joints or seams. This characteristic makes them ideal for lining and protecting the different zones of a blast furnace. One typical application of monolithic refractories in blast furnaces is the lining of the hearth. The hearth is the bottom part of the furnace where molten iron and slag accumulate. Monolithic refractories are used to create a durable and heat-resistant lining that can withstand the extreme temperatures and chemical reactions occurring in this area. Another common application is the lining of the bosh, which is the transition zone between the hearth and the stack of the blast furnace. The bosh is subjected to high temperatures and mechanical stresses due to the movement of the burden materials. Monolithic refractories with high thermal shock resistance and abrasion resistance are used to ensure the longevity and efficiency of the bosh. Monolithic refractories are also used for the lining of the stack and the tuyere area. The stack is the vertical part of the furnace where the reduction of iron ore takes place. The tuyere area is where the hot blast of air is injected into the furnace. Both of these areas require refractories that can withstand high temperatures, chemical reactions, and mechanical stresses. Furthermore, monolithic refractories are used for repairs and maintenance in blast furnaces. Due to the harsh conditions inside the furnace, the lining may deteriorate over time. Monolithic refractories can be easily applied as patching materials to restore the integrity of the lining and extend the furnace's lifespan. In summary, the typical applications of monolithic refractories in blast furnaces include lining the hearth, bosh, stack, and tuyere area, as well as for repairs and maintenance. These refractories provide excellent thermal shock resistance, abrasion resistance, and durability, making them essential for the efficient operation of blast furnaces in the iron and steel industry.

- Q: What are the advantages of using self-flow castables in the iron and steel industry?

- The advantages of using self-flow castables in the iron and steel industry are numerous. Firstly, these castables have excellent flowability, which allows for easy and efficient installation. This results in reduced labor costs and time savings during the installation process. Additionally, self-flow castables have high strength and excellent resistance to thermal shock. This makes them highly durable and capable of withstanding the extreme temperatures and thermal cycling conditions present in iron and steel applications. As a result, they provide long-lasting and reliable performance in these demanding environments. Furthermore, self-flow castables offer excellent dimensional stability, ensuring that the refractory lining maintains its shape and integrity even under high mechanical loads and thermal stresses. This feature is crucial in maintaining the structural integrity of the furnaces, ladles, and other equipment used in the iron and steel industry. Moreover, self-flow castables have low water requirements, reducing the risk of cracking and spalling during drying and firing. This leads to improved product quality and increased refractory lifespan. Overall, the advantages of using self-flow castables in the iron and steel industry include easy installation, high strength, thermal shock resistance, dimensional stability, and improved product quality. These benefits contribute to increased efficiency, reduced downtime, and cost savings for iron and steel manufacturers.

- Q: How do monolithic refractories withstand the thermal cycling in aluminum smelting applications?

- Monolithic refractories are specifically designed to withstand the extreme thermal cycling conditions encountered in aluminum smelting applications. The unique properties of these refractories allow them to endure the rapid and repetitive heating and cooling cycles without significant damage or failure. One key feature of monolithic refractories is their excellent thermal shock resistance. This property enables them to withstand sudden temperature changes without cracking or spalling. During the aluminum smelting process, the refractories are exposed to extreme temperatures when molten aluminum is poured into the molds or when the molten metal comes in contact with the refractory lining. The refractories must be able to absorb and dissipate the heat rapidly to prevent thermal shock damage. Another important characteristic of monolithic refractories is their high thermal conductivity. This property facilitates the efficient transfer of heat away from the refractory lining, reducing the risk of thermal stress and thermal fatigue. The refractories can effectively disperse the heat generated during the smelting process, minimizing the temperature differentials within the lining and preventing cracks or fractures. Furthermore, monolithic refractories possess good chemical resistance, which is crucial in aluminum smelting applications. They are formulated to resist the corrosive effects of molten aluminum and other chemicals present in the smelting process. This resistance helps to maintain the integrity of the refractory lining and prolong its service life. Additionally, monolithic refractories are often reinforced with fibers or other structural materials to enhance their mechanical strength and durability. These reinforcements provide added resistance against mechanical stresses, such as thermal expansion and contraction, which occur during the thermal cycling process. In conclusion, monolithic refractories are designed to withstand the thermal cycling conditions encountered in aluminum smelting applications. Their excellent thermal shock resistance, high thermal conductivity, good chemical resistance, and mechanical strength allow them to endure the extreme temperature fluctuations without significant damage. These refractories play a crucial role in maintaining the integrity and efficiency of the smelting process in the aluminum industry.

Send your message to us

Monolithic Refractories for Iron and Steel Industry - Ladle Shroud Long Nozzle Chinese Steelmaking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords