modern steel structure sculpture projects

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

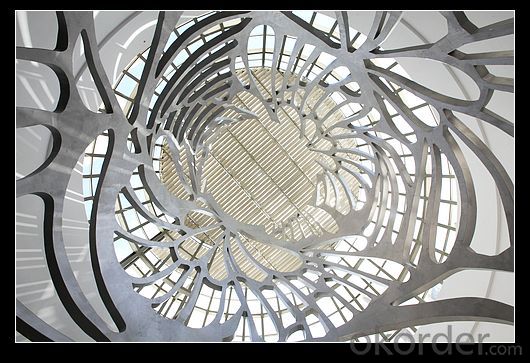

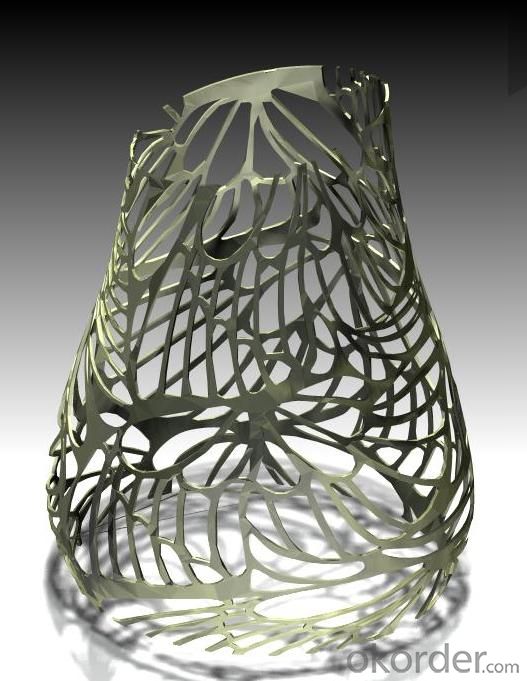

Modern steel structure sculpture projects

Guangdong sunrise steel structure company ,which was established in 2007, covers an area of 30000 M2, is a modern enterprise specialized in processing and manufacturing various kinds of steel structures buildings over 300. Such as : steel canopy, steel spiral staircase and steel art sculpture,steel container house. steel warehouse.

We have 100 unites equipment for large and medium-sized metal processing, welding, assembly process

In 2013, Sunrise cooperated with MGM Group to create a giant metal Butterfly engraving, which is sitting in the lobby of MGM Grand Sanya. It’s 22 meters tall, the maximum diameter is15.5 meters, coordinates of the points to reach 5500. Sunrise completed all works and fulfilled the goal as planned after overcoming many difficulties. Fully demonstrated sunrise has a strong strength in art landscape steel structure.

Packing: As per customer's requirement by bulk or removable storage rack

Lead time:25 days to 30 days after signed the contract.

FAQ:

Does your company is a factory or trade company?

We are factory, so you will enjoy the best price and competitive price.

What’s the quality assurance you provided and how do you control quality ?

Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc.

Can you offer designing Prefabricated Steel Warehouse service?

Yes, we have more than 30 design engineers. We could design full solution drawings as per your requirments. They use software: Auto CAD,PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel)V12.0.etc.

Do you offer guiding installation on site overseas for Prefabricated Steel Warehosue ?

Yes, we can provide the service of installation, supervision and training by extra. We can send our professional technical engineer to surpervise installation on site overseas. They have succeeded in many countries, such as Iraq, Dubai, South Africa, Algerial, Ghana

- Q: How are steel structures designed for efficient use of water resources?

- Steel structures can be designed to promote efficient use of water resources in several ways. Firstly, steel is a highly durable material that can withstand harsh weather conditions and has a long lifespan. This means that steel structures require less maintenance and repair, reducing the need for water-intensive activities such as cleaning and painting. Additionally, steel structures can incorporate rainwater harvesting systems, which collect and store rainwater for various purposes. This water can be used for irrigation, flushing toilets, or even for industrial processes within the structure. By utilizing rainwater, steel structures can reduce their reliance on freshwater sources, ultimately conserving water resources. Furthermore, steel structures can be designed with efficient plumbing systems that reduce water wastage. Low-flow fixtures, such as faucets and toilets, can be installed to minimize water consumption without compromising functionality. Additionally, leak detection systems and water-efficient irrigation systems can be integrated into the structure's design to prevent water leaks and optimize irrigation practices. Moreover, steel structures can be designed with green roofs or rooftop gardens, which help reduce the heat island effect and improve stormwater management. These green features help to retain rainwater, reducing runoff and allowing for natural filtration before it enters water bodies. This promotes sustainable water management and reduces the strain on municipal water systems. In conclusion, steel structures can be designed to maximize the efficient use of water resources through various strategies such as rainwater harvesting, efficient plumbing systems, green roofs, and water-efficient irrigation systems. By incorporating these design elements, steel structures contribute to water conservation efforts and promote sustainable water management practices.

- Q: How do steel structures handle soil-structure interaction?

- Steel structures handle soil-structure interaction through proper design and construction techniques. The design takes into account the characteristics of the soil, such as its strength, stiffness, and settlement behavior. The foundation of the steel structure is designed to distribute the loads from the structure to the soil in a way that minimizes settlement and ensures stability. Various measures, like using deep foundations or ground improvement techniques, may be employed to mitigate the effects of soil-structure interaction. Additionally, regular monitoring and maintenance are crucial to identify any potential issues and ensure the long-term performance of the steel structure in relation to the surrounding soil.

- Q: What are the design considerations for steel mezzanines?

- Some key design considerations for steel mezzanines include structural stability, load-bearing capacity, fire resistance, accessibility, and integration with the existing building. Additionally, factors such as the intended use, site conditions, and local building codes should also be taken into account during the design process.

- Q: What are the considerations when designing steel structures for logistics and distribution centers?

- When designing steel structures for logistics and distribution centers, several key considerations need to be taken into account. Firstly, the structural design should prioritize efficient space utilization to accommodate various storage and handling systems. This involves considering the column grid layout, clear heights, and overall layout flexibility to optimize workflow and maximize storage capacity. Additionally, the structural design must ensure the ability to support heavy loads, as logistics and distribution centers typically handle large volumes of goods. This includes considering the weight and distribution of stored materials, as well as the potential for dynamic loads caused by equipment and machinery. Furthermore, the design should consider the incorporation of durable and corrosion-resistant materials to withstand the demands of a busy logistics environment. Steel is often the preferred choice due to its strength and longevity, but proper coatings or galvanization should be applied to protect against corrosion. Fire safety is another crucial consideration. Adequate fire protection measures, such as fire-resistant coatings, fire suppression systems, and proper compartmentalization, should be integrated into the structural design to ensure the safety of goods and personnel. Lastly, the design should account for future expansion and adaptability. As the logistics industry evolves, the ability to easily modify or expand the facility to meet changing needs is essential. This may involve considering column spacing, roof height, and floor loading capacity to accommodate potential future growth. Ultimately, a successful design for steel structures in logistics and distribution centers requires a comprehensive understanding of the operational requirements, as well as a careful balance between functionality, efficiency, safety, and adaptability.

- Q: What are the factors that affect the maintenance and repair of a steel structure over time?

- There are several factors that can affect the maintenance and repair of a steel structure over time. Firstly, environmental conditions such as exposure to moisture, extreme temperatures, and corrosive substances can cause deterioration and rusting of the steel. Secondly, the quality of the initial construction and the materials used can impact the structure's durability and susceptibility to damage. Additionally, the frequency and type of usage, as well as the level of maintenance performed, can influence the need for repairs. Finally, external factors such as accidents, natural disasters, or changes in building codes and regulations can also contribute to the maintenance and repair requirements of a steel structure.

- Q: What are the considerations for designing steel canopies and shade structures?

- When designing steel canopies and shade structures, several considerations need to be taken into account. These include the intended purpose and use of the structure, the local climate and weather conditions, the desired aesthetic appeal, structural stability and durability, as well as the budget and available resources. Additionally, factors such as the choice of materials, the method of installation, and any necessary permits or regulations should also be considered to ensure a successful and functional design.

- Q: What are the considerations for designing steel retail buildings?

- Some considerations for designing steel retail buildings include the desired layout and functionality of the space, the structural integrity and load-bearing capacity required to support the building and its contents, the aesthetic appeal and branding elements to attract customers, the energy efficiency and sustainability features to minimize operational costs, the compliance with local building codes and regulations, and the flexibility for potential future expansions or modifications. Additionally, factors such as budget, construction timeline, and the specific needs of the retail business should also be taken into account during the design process.

- Q: How are steel structures used in the construction of laboratories?

- Steel structures are commonly used in the construction of laboratories due to their numerous benefits and characteristics. First and foremost, steel is known for its strength and durability, making it an ideal material for constructing laboratory buildings that need to withstand heavy loads and potential hazards. Steel structures can support the weight of specialized equipment, machinery, and large-scale experiments, ensuring the safety and stability of the laboratory. Moreover, steel is highly resistant to fire, which is a critical factor in laboratory construction. Laboratories often deal with hazardous chemicals and materials, making fire safety a top priority. Steel structures have a high melting point and do not ignite, providing a reliable level of protection in case of a fire emergency. Additionally, steel structures offer flexibility in design and construction. Steel beams and columns can be easily fabricated and customized to meet specific laboratory requirements, allowing for efficient use of space and accommodating various research needs. The lightweight nature of steel also enables faster construction, minimizing project timelines and costs. Furthermore, steel structures are known for their sustainability and environmental benefits. Steel is a 100% recyclable material, which reduces waste and promotes a circular economy. By using steel in laboratory construction, builders contribute to a greener and more sustainable construction industry. Overall, steel structures play a crucial role in laboratory construction by providing strength, durability, fire resistance, design flexibility, and sustainability. These characteristics make steel an ideal choice for creating safe, functional, and efficient laboratory spaces that can withstand the unique demands of scientific research and experimentation.

- Q: What are the different types of steel facades and curtain walls used in buildings?

- Buildings commonly use various types of steel facades and curtain walls, each with its own advantages and visual appeal. These types include: 1. Unitized Curtain Wall: Ideal for tall structures, this option involves pre-assembled units made of aluminum frames and glass panels. Factory-built units are swiftly installed on-site, enabling faster construction. 2. Stick Curtain Wall: Assembled on-site, this curtain wall comprises individual installation of steel or aluminum frames, followed by glass panel addition. Stick curtain walls offer design flexibility and can be customized to meet specific architectural demands. 3. Point-Supported Glass Facade: This facade deploys stainless steel tension cables or rods to support large glass panels, which are typically fixed at specific points. This approach achieves a sleek and minimalist appearance. 4. Steel Plate Facade: Steel plates are directly attached to the building's structural frame to create these facades. They offer durability, strength, and the ability to achieve diverse architectural designs. 5. Louvered Facade: These facades incorporate angled steel or aluminum louvers fixed to the building's exterior. Louvers provide shade, privacy, ventilation, and add a distinctive visual element to the facade. 6. Perforated Steel Facade: This option involves steel panels with patterns or perforations created through punching or laser-cutting. Perforated steel facades enable controlled light transmission and visually captivating designs. 7. Corrugated Steel Facade: Comprised of steel sheets formed into waves or ridges, corrugated steel facades are commonly found in industrial or agricultural buildings. However, they are also used in contemporary architectural designs. Each steel facade or curtain wall type presents unique advantages and aesthetic qualities. The decision regarding which type to use depends on factors such as architectural design, budget, energy efficiency requirements, and desired visual appearance.

- Q: What are the advantages of using steel structures in housing construction?

- There are several advantages of using steel structures in housing construction. Firstly, steel is a highly durable and long-lasting material, providing a strong framework for the house. It can withstand extreme weather conditions, such as hurricanes and earthquakes, better than traditional building materials. Secondly, steel is lightweight, making it easier and faster to construct houses using steel structures, reducing construction time and costs. Additionally, steel is a sustainable material as it is recyclable and can be used in multiple projects, reducing environmental impact. Lastly, steel structures offer great design flexibility, allowing for open floor plans and large spans, giving homeowners the freedom to create their desired living spaces.

Send your message to us

modern steel structure sculpture projects

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords