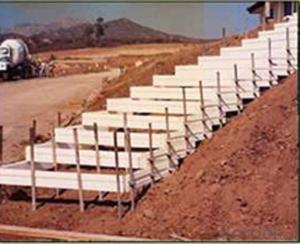

Layer Scaffolding Formwork Adjustable Scaffolding Leg with New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Layer Scaffolding Formwork Adjustable Scaffolding Leg with New Design

Plastic Formwork Concrete Formwork Scaffolding Manufacturer Scaffolding Spanners with New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Layer Scaffolding Formwork Adjustable Scaffolding Leg with New Design

Layer Scaffolding Formwork Adjustable Scaffolding Leg with New Design

Layer Scaffolding Formwork Adjustable Scaffolding Leg with New Design

Layer Scaffolding Formwork Adjustable Scaffolding Leg with New Design

- Q: Can steel frame formwork be used for curved or irregularly shaped concrete structures?

- Curved or irregular concrete structures can indeed utilize steel frame formwork. The malleability of steel permits easy manipulation and shaping to accommodate diverse curves and irregularities in the concrete structure. The steel frame formwork provides essential support and stability during the pouring and curing stages, guaranteeing the desired concrete shape. It can be adjusted and tailored according to project-specific requirements, rendering it a versatile option for forming curved or irregular structures. Furthermore, steel frame formwork offers robustness and resilience, ensuring its ability to withstand the pressures and forces exerted throughout the concrete placement and curing process. In summary, steel frame formwork proves to be a suitable choice for achieving intricate and distinctive shapes in concrete construction projects.

- Q: What are the common forms of high-rise building construction?

- 7 to 9 layers of plywood, used for beam, column, floor, roof, water tank model

- Q: In the process of construction of reinforced concrete frame structure, the main contents of the quality inspection and monitoring of formwork engineering

- The specifications, quality and fastening conditions of all kinds of connecting pieces and supporting parts (the use of torque wrench for fasteners); 3, the overall stability of the supporting points and the combined steel formwork;

- Q: How does steel frame formwork handle concrete pouring in windy conditions?

- Steel frame formwork is designed to withstand windy conditions during concrete pouring. The solid and sturdy structure of steel frame formwork provides stability and strength, which minimizes the impact of strong winds on the concrete pouring process. Steel frame formwork is constructed with durable steel frames that are securely anchored to the ground. This anchoring system ensures that the formwork remains in place even in high winds, preventing any displacement or movement that could compromise the integrity of the concrete structure. Additionally, the steel frame formwork is often reinforced with diagonal bracings or tie rods to further enhance its stability. In windy conditions, the steel frame formwork acts as a barrier, shielding the concrete from direct exposure to the wind. This helps in maintaining the desired consistency and quality of the concrete during pouring. The solid construction of the formwork also prevents any unwanted deformations or distortions caused by wind pressure. To further mitigate the effects of wind, additional precautions can be taken during the concrete pouring process. For instance, pouring concrete in windy conditions can be done in smaller sections to minimize the exposure time and reduce the risk of wind-induced complications. Moreover, using windbreakers or wind barriers around the construction site can provide additional protection from gusts of wind. Overall, steel frame formwork is designed to handle concrete pouring in windy conditions by providing a stable and secure structure that protects the concrete and ensures the successful completion of the construction project.

- Q: What are the different types of finishes available with steel frame formwork?

- Steel frame formwork offers several different types of finishes, each with its own advantages and visual appeal. 1. The smooth finish is achieved using high-quality steel forms, resulting in a sleek and polished surface. It is ideal for projects that require a clean and professional appearance, such as commercial buildings, bridges, and infrastructure projects. 2. Textured finishes can be achieved by using specialized form liners or applying coatings to the steel forms. This adds texture and patterns to the concrete surface, creating a visually appealing look. Textured finishes are commonly used in architectural projects like facades, walls, and decorative panels. 3. Exposed aggregate finishes can be achieved through special form liners or by exposing the aggregate in the concrete surface through techniques like sandblasting or water jetting. This type of finish showcases the natural beauty of aggregates, resulting in a decorative and visually interesting surface. It is often used in outdoor applications like sidewalks and driveways. 4. Stamped finishes can be achieved using textured form liners or by stamping the concrete surface with specialized tools. This replicates the appearance of natural materials like brick, stone, or wood. Stamped finishes are commonly used in residential projects like patios, walkways, and pool decks to achieve a high-end and decorative look. 5. Polished finishes are achieved by grinding and polishing the concrete surface to a smooth and reflective shine. This type of finish is not applied directly to the steel forms but is achieved after the concrete has cured. Polished finishes are often used in commercial and industrial projects as they provide a durable and low-maintenance surface. In conclusion, the choice of finish for steel frame formwork depends on project requirements, design aesthetics, and desired durability and maintenance level. Seeking guidance from a professional contractor or formwork supplier can help determine the most suitable finish for a specific project.

- Q: How does steel frame formwork differ from other types of formwork?

- Steel frame formwork differs from other types of formwork in several ways. Firstly, steel frame formwork is made of steel, which makes it extremely strong and durable. It can withstand heavy loads and is resistant to warping or bending. This makes it ideal for construction projects that require a high level of strength and stability. Secondly, steel frame formwork is highly versatile. It can be easily customized and adjusted to fit different shapes and sizes of structures. This flexibility allows for the creation of complex and unique designs that may not be possible with other types of formwork. Additionally, steel frame formwork offers superior stability and accuracy. The steel frames provide excellent support and ensure that the formwork remains in place and does not shift during the pouring and curing of concrete. This results in better quality and more precise construction. Furthermore, steel frame formwork has a longer lifespan compared to other types of formwork. Its durability and resistance to wear and tear mean that it can be used for multiple projects, making it a cost-effective option in the long run. Lastly, steel frame formwork is relatively quick and easy to assemble and dismantle. The steel frames can be easily transported and assembled on-site, saving time and labor costs. This efficiency is especially beneficial for projects with tight deadlines or limited resources. In summary, steel frame formwork stands out from other types of formwork due to its strength, versatility, stability, durability, and ease of use. These qualities make it an excellent choice for construction projects that require a high level of performance and efficiency.

- Q: What types of construction projects are steel frame formwork commonly used for?

- A wide range of construction projects necessitate the use of steel frame formwork for the construction of reinforced concrete structures. Some common examples of such projects include: 1. High-rise buildings: Steel frame formwork is frequently utilized in the construction of tall buildings due to its ability to provide a robust and long-lasting framework for the concrete structure. 2. Bridges: Steel frame formwork is also commonly employed in bridge construction as it can endure heavy loads and offer the necessary support for the concrete components. 3. Industrial structures: Factories, warehouses, and power plants often rely on steel frame formwork for their construction. This is because it enables the creation of large and intricate concrete structures, which are often necessary in industrial settings. 4. Infrastructure projects: Tunnels, dams, and water treatment plants are examples of infrastructure projects where steel frame formwork can be found. These projects typically involve the construction of sizable concrete structures that require a dependable and sturdy formwork system. 5. Residential buildings: Steel frame formwork is also utilized in the construction of residential buildings, particularly those with multiple floors. The steel frame ensures stability and safeguards the structural integrity of the building throughout the construction process and beyond. In summary, steel frame formwork is a versatile and widely utilized construction method that is commonly employed in various construction projects that require reinforced concrete structures.

- Q: Can steel frame formwork be used for educational and institutional buildings construction?

- Yes, steel frame formwork can be used for educational and institutional buildings construction. Steel frame formwork is a versatile and durable construction method that is commonly used in various types of buildings, including educational and institutional structures. The use of steel frame formwork offers several advantages for these types of buildings. Firstly, steel is a strong and reliable material that can withstand heavy loads and provide structural stability to the building. This is particularly important in educational and institutional buildings where the safety of occupants is a top priority. Additionally, steel frame formwork allows for flexibility in design and construction. It can be easily adjusted and modified to accommodate different architectural requirements and functional needs of educational and institutional buildings. This is especially beneficial in educational buildings where classrooms, laboratories, and other spaces may need to be reconfigured or expanded in the future. Moreover, steel frame formwork is a time-efficient construction method. The prefabricated steel frames can be quickly assembled on-site, reducing the overall construction time and ensuring that the building is completed on schedule. This is crucial in educational and institutional buildings where there may be strict deadlines to meet, such as the start of a new academic year or the opening of a new facility. In conclusion, steel frame formwork is a suitable and efficient construction method for educational and institutional buildings. Its strength, flexibility, and time-saving qualities make it an ideal choice for these types of structures.

- Q: How is steel frame formwork secured in place?

- Steel frame formwork is secured in place by using a combination of clamps, bolts, wedges, and braces to ensure stability and prevent movement during the concrete pouring process.

- Q: How does steel frame formwork handle the placement of precast concrete elements within the concrete structure?

- Steel frame formwork is a highly efficient and versatile system that is specifically designed to handle the placement of precast concrete elements within a concrete structure. This type of formwork consists of steel frames that are assembled to create a temporary mold or structure, which is used to shape the concrete during the construction process. When it comes to placing precast concrete elements, the steel frame formwork offers several advantages. Firstly, the steel frames can be easily adjusted and aligned to match the size and shape of the precast elements, ensuring a precise fit. This is crucial as it helps to minimize any gaps or irregularities between the precast elements and the surrounding concrete structure. Additionally, the steel frame formwork provides the necessary support and stability for the precast elements. The strong and rigid steel frames can withstand the weight and pressure exerted by the precast elements, ensuring that they remain in position during the pouring and curing of the concrete. Furthermore, the steel frame formwork allows for efficient installation and removal of the precast elements. The frames can be easily assembled and disassembled, enabling quick and smooth installation of the precast elements. This saves time and labor costs, making the construction process more efficient. In conclusion, steel frame formwork is a reliable and effective system for handling the placement of precast concrete elements within a concrete structure. Its flexibility, stability, and ease of use make it an ideal choice for ensuring a seamless integration of precast elements into the overall construction process.

Send your message to us

Layer Scaffolding Formwork Adjustable Scaffolding Leg with New Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches