Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Plastic Formwork Concrete Formwork Parts Of A Tubular Scaffolding Scaffolding Importers Low Price

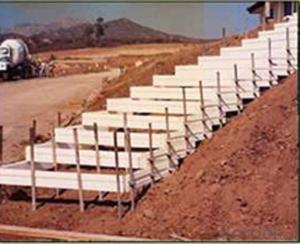

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

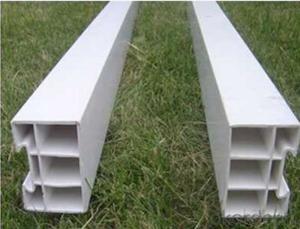

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

FAQ

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

We have organized several common questions for our clients, may help you sincerely:

1)How is the Packaging Details?

In bags or as the requirement ofcustomers.

2)How long can we receive the product after purchase?

Lead time is about 30days after getting the signed PI and deposit.

- Q: What are the considerations for selecting the appropriate formwork for different concrete curing durations?

- When selecting the appropriate formwork for different concrete curing durations, several considerations need to be taken into account. Firstly, the type of formwork material should be chosen based on its ability to withstand the curing duration without warping or deteriorating. For shorter curing periods, materials like timber or plywood may be suitable, while for longer periods, steel or aluminum formwork may be more appropriate. The complexity and intricacy of the concrete structure also play a role in formwork selection. For complex shapes or intricate designs, modular formwork systems that can be easily adjusted and reused may be preferred. On the other hand, simple and repetitive structures may benefit from traditional formwork methods, such as timber or steel frames. The cost and availability of formwork materials should also be considered. Some materials may be more expensive or harder to find, which could affect the overall project budget and timeline. It is important to strike a balance between the desired curing duration and the cost-effectiveness of the chosen formwork system. Lastly, safety is paramount when selecting formwork. The chosen formwork system should be able to support the weight of the wet concrete and any additional loads, ensuring the stability and integrity of the structure during the curing process. Adequate bracing and shoring must be considered to prevent any collapse or failure. In summary, the considerations for selecting the appropriate formwork for different concrete curing durations include the type of formwork material, complexity of the structure, cost and availability, and ensuring safety and stability throughout the curing process.

- Q: Can steel frame formwork be used for curved or irregular shaped structures?

- Yes, steel frame formwork can be used for curved or irregular shaped structures. Its flexibility and strength allow for the creation of customized formwork that can be easily adjusted to match the desired shape of the structure. This makes steel frame formwork a suitable choice for challenging architectural designs that require curved or irregular shapes.

- Q: What is the lifespan of a steel frame formwork system?

- The lifespan of a steel frame formwork system can vary depending on factors such as maintenance, usage, and environmental conditions. However, with proper care and regular maintenance, a steel frame formwork system can last for several decades.

- Q: How does steel frame formwork handle different types of reinforcement?

- The versatility and efficiency of the steel frame formwork system enable it to easily handle diverse types of reinforcement in construction projects. The main advantage of this system lies in its flexibility, which allows for seamless integration of various reinforcement materials, such as steel bars or mesh, without compromising the structural integrity of the formwork. The design of the steel frame formwork system caters to the weight and pressure exerted by the reinforcement materials, providing a robust and stable platform for their placement and installation. This ensures that the reinforcement stays in the desired position throughout the construction process. Additionally, the formwork system allows for convenient adjustment and modification to accommodate different reinforcement configurations. The steel frames can be easily adapted to the required shape and size, allowing for the inclusion of vertical or horizontal bars, as well as various reinforcement spacings. Furthermore, the steel frame formwork system boasts exceptional durability and strength, which are vital for handling diverse types of reinforcement. It can withstand the considerable loads and pressures encountered during concrete pouring and curing, guaranteeing the secure placement of the reinforcement. Overall, the steel frame formwork system is an excellent choice for contractors and engineers who aim to efficiently and effectively incorporate different reinforcement configurations into their construction projects. Its flexibility, adaptability, and strength make it an ideal option for such endeavors.

- Q: Can steel frame formwork be used for both single-storey and multi-storey construction?

- Yes, steel frame formwork can be used for both single-storey and multi-storey construction. Its versatility and strength make it suitable for various construction projects of different scales, providing a durable and efficient solution for forming concrete structures.

- Q: Are there any specific safety regulations or standards for using steel frame formwork?

- Yes, there are specific safety regulations and standards for using steel frame formwork. These regulations and standards are put in place to ensure the safety of workers and the successful completion of construction projects. One of the primary regulations is the Occupational Safety and Health Administration (OSHA) standards. OSHA sets forth guidelines for the use of steel frame formwork to prevent accidents and injuries. These guidelines include requirements for proper training and certification of workers, the use of personal protective equipment (PPE) such as hard hats and safety harnesses, and the implementation of safety procedures such as fall protection systems and proper scaffolding. In addition to OSHA standards, there are industry-specific standards and codes that govern the use of steel frame formwork. For example, the American Concrete Institute (ACI) provides guidelines and standards for concrete formwork, including steel frame formwork. These standards cover aspects such as the design and construction of formwork systems, the use of proper bracing and shoring, and the inspection and maintenance of formwork. Furthermore, many countries have their own specific regulations and standards for using steel frame formwork. These regulations may vary depending on the jurisdiction and local building codes. It is important for construction companies and contractors to be aware of and comply with these regulations to ensure the safety and legality of their projects. Overall, using steel frame formwork requires adherence to specific safety regulations and standards. These regulations are in place to protect workers, prevent accidents, and ensure the quality and integrity of construction projects.

- Q: What are the safety precautions for working with steel frame formwork?

- When working with steel frame formwork, there are several important safety precautions that should be followed to ensure the well-being of workers and prevent accidents. 1. Personal Protective Equipment (PPE): It is crucial for workers to wear the appropriate PPE, including safety helmets, safety glasses, gloves, and steel-toed boots. This protective gear helps to minimize the risk of head injuries, eye injuries, hand injuries, and foot injuries. 2. Training and Education: Workers should receive proper training and education on the use of steel frame formwork. This includes understanding the equipment, its limitations, and how to safely assemble and dismantle it. Adequate training helps to prevent accidents caused by human error or negligence. 3. Inspection and Maintenance: Regular inspection and maintenance of steel frame formwork are essential. It is important to check for any damaged or worn-out components, such as bolts, joints, or scaffolding. Any faulty or defective parts should be repaired or replaced immediately to avoid potential accidents. 4. Secure Foundation: The formwork should be set up on a stable and level foundation. This helps to prevent any sudden collapse or shifting of the structure, reducing the risk of accidents. The ground should be adequately prepared and compacted before placing the formwork. 5. Secure Anchoring: Steel frame formwork should be properly anchored or supported to prevent any movement or collapse during construction activities. This can be achieved by using sturdy braces, ties, or supports to ensure stability and structural integrity. 6. Fall Protection: Adequate fall protection measures should be in place. This includes installing guardrails, safety nets, or personal fall arrest systems (PFAS) to prevent workers from falling from heights. It is essential to provide proper training on the use of fall protection equipment and ensure its correct installation. 7. Communication: Clear communication among workers is crucial for maintaining safety. Workers should be trained to use appropriate hand signals or communication devices to coordinate their movements and avoid any potential accidents. 8. Safe Lifting and Handling: Workers should be trained on safe lifting techniques and the proper use of lifting equipment, such as cranes or hoists, to minimize the risk of back injuries or strains. 9. Weather Conditions: Extreme weather conditions, such as heavy rain, strong winds, or freezing temperatures, can affect the stability and safety of steel frame formwork. It is important to monitor weather forecasts and take appropriate measures, such as suspending work during adverse conditions or providing additional support to the structure. 10. Emergency Preparedness: Workers should be aware of emergency procedures, such as evacuation routes, first aid locations, and the location of fire extinguishers. Regular drills and training sessions on emergency response can help ensure workers are prepared to handle any unexpected situations. By following these safety precautions, workers can significantly reduce the risk of accidents and injuries when working with steel frame formwork. It is important to prioritize safety at all times and take necessary measures to create a secure working environment.

- Q: Can steel frame formwork be used in combination with architectural lighting systems?

- Certainly, architectural lighting systems can be combined with steel frame formwork. Steel frame formwork is an adaptable and robust construction method suitable for various uses, including the construction of intricate shapes and structures. Architectural lighting systems, on the other hand, are design elements that improve the aesthetics and functionality of a space. These systems are often incorporated into the overall design of a building or structure to emphasize specific areas, establish an ambiance, or showcase architectural features. It is essential to consider the placement and integration of architectural lighting systems when using steel frame formwork. The solid foundation and structure provided by the formwork allow for the mounting or integration of lighting fixtures. The formwork can be customized to accommodate the wiring and installation of the lighting systems, ensuring a seamless and visually pleasing integration. Moreover, the strength and durability of steel frame formwork make it suitable for supporting the weight of lighting fixtures and any associated electrical components. This ensures the stability and security of the lighting systems over time. To conclude, steel frame formwork can indeed be combined with architectural lighting systems. By integrating the two, visually striking and functional structures can be created, effectively utilizing lighting to enhance the overall design.

- Q: What are the different methods of fixing and anchoring steel frame formwork?

- There are several methods for fixing and anchoring steel frame formwork. Some common methods include using steel nails or screws to secure the formwork to wooden or metal stakes driven into the ground. Another method is using adjustable clamps or brackets to attach the formwork to existing structures or columns. Additionally, steel frame formwork can be anchored by using steel rods or bolts to connect the formwork to the concrete foundation or surrounding structures. These methods provide stability and ensure that the formwork remains in place during the concrete pouring and setting process.

- Q: What are the different components of a steel frame formwork system?

- A steel frame formwork system is composed of multiple components that collaborate to offer support and structure during concrete construction processes. These components encompass: 1. Steel frames: The fundamental element of a steel frame formwork system is the steel frame itself. These frames are usually constructed from high-quality steel and are engineered to be sturdy, long-lasting, and capable of withstanding the weight and pressure exerted by the concrete. 2. Panels: Steel frame formwork systems also incorporate panels that are affixed to the steel frames. These panels are commonly made of plywood or metal and provide a seamless surface onto which the concrete can be poured. The panels are easily installed, removed, and replaced, resulting in a highly efficient and cost-effective system. 3. Wedges and clamps: Wedges and clamps are employed to secure the panels to the steel frames. Wedges are inserted between the panel and the frame to hold them in position, while clamps offer additional support and stability. These components ensure that the formwork system remains secure and taut throughout the concrete pouring and curing stages. 4. Adjustable props and supports: Adjustable props and supports are utilized in a steel frame formwork system to provide extra support and stability. These props and supports are easily modifiable and can be set at various heights to accommodate the desired formwork dimensions. 5. Accessories: A range of accessories is also included in a steel frame formwork system, such as corner brackets, alignment clamps, connectors, and anchor bolts. These accessories aid in achieving proper alignment and connection of the formwork components, resulting in a robust and dependable system. All in all, a steel frame formwork system presents a versatile and efficient solution for concrete construction projects. Its diverse components collaborate to offer a strong and reliable support structure, enabling the precise pouring and shaping of concrete to create desired structures.

Send your message to us

Concrete Slab Formwork Scaffolding System Formwork Buy Scaffolding For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords