Scaffolding Screw Jack Formwork Scaffolding China Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Screw Jack Formwork Scaffolding China Low Price

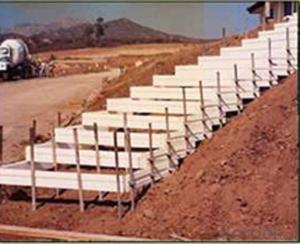

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

Scaffolding Screw Jack Formwork Scaffolding China Low Price

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Screw Jack Formwork Scaffolding China Low Price

Scaffolding Screw Jack Formwork Scaffolding China Low Price

- Q: What are the factors that determine the design of steel frame formwork?

- There are several factors that determine the design of steel frame formwork. Firstly, the type and size of the structure being constructed play a crucial role in determining the design of steel frame formwork. Different types of structures, such as high-rise buildings, bridges, or industrial facilities, have varying requirements in terms of load-bearing capacity, shape, and dimensions. The design of the steel frame formwork must be able to accommodate these specific requirements. Secondly, the expected concrete pressure exerted on the formwork is another important factor. The concrete pressure is influenced by factors such as the height of the structure, the type of concrete mix used, and the rate of concrete pouring. The design of the steel frame formwork should be able to withstand the anticipated concrete pressure without deforming or collapsing. Thirdly, the construction schedule and project timeline also impact the design of steel frame formwork. If the construction requires a fast-paced schedule with quick turnaround times, the formwork design should facilitate easy assembly, disassembly, and reusability. On the other hand, if the project timeline allows for longer construction periods, the design can prioritize durability and longevity. Furthermore, considerations such as budget, availability of materials, and construction site conditions also influence the design of steel frame formwork. The design should be cost-effective, utilizing materials that are readily available and suitable for the construction site environment. Additionally, factors like weather conditions, topography, and site accessibility may affect the design by requiring additional reinforcements or modifications to ensure stability and safety. Lastly, compliance with local building codes, regulations, and safety standards is a crucial factor in the design of steel frame formwork. The formwork design should adhere to these guidelines to ensure the structural integrity of the construction and the safety of workers. In summary, the design of steel frame formwork is determined by various factors including the type and size of the structure, expected concrete pressure, construction schedule, budget, availability of materials, construction site conditions, and compliance with building codes and safety standards. A comprehensive understanding of these factors is essential for designing a formwork system that meets the specific requirements of a construction project.

- Q: Can steel frame formwork be used for commercial buildings?

- Yes, steel frame formwork can be used for commercial buildings. Steel frame formwork is a versatile and durable solution that is commonly used in the construction industry for various types of buildings, including commercial structures. It provides excellent strength and stability, allowing for the construction of high-rise buildings and large-scale commercial projects. Steel frame formwork is highly adaptable and can be easily customized to meet the specific requirements of different commercial building designs. Additionally, it offers a high-quality finish and can be reused multiple times, making it a cost-effective choice for commercial construction projects.

- Q: What are the different components of steel frame formwork?

- The different components of steel frame formwork typically include: 1. Panels: Steel frame formwork panels are the main component of the system. These panels are usually made of steel or aluminum and are designed to be lightweight yet sturdy. They come in various sizes and shapes, such as rectangular or square, and are available in different thicknesses based on the required strength and load-bearing capacity. 2. Connecting pins: Connecting pins are used to connect the panels together, ensuring a tight and secure formwork system. These pins are usually made of steel and are inserted through pre-drilled holes in the panels, providing stability and preventing any movement or displacement during concrete pouring. 3. Wedges: Wedges are used in conjunction with the connecting pins to further secure the formwork system. They are typically made of steel or plastic and are inserted between the panels and pins, creating a tight fit and preventing any gaps or spaces that could lead to leakage or uneven concrete placement. 4. Props: Props are vertical support devices used to provide additional strength and stability to the formwork system. They are usually made of steel and are adjustable in height, allowing for flexibility in formwork installation. Props are essential in supporting the weight of the concrete and the formwork itself, ensuring a safe and reliable construction process. 5. Braces: Braces are horizontal or diagonal supports that are used to reinforce the formwork system and prevent any buckling or bending of the panels. They are typically made of steel and are installed at regular intervals to provide additional stability and rigidity to the formwork structure. 6. Formwork accessories: In addition to the main components, steel frame formwork may also include various accessories such as clamps, ties, and brackets. These accessories are used to secure the formwork system to the existing structure, align the panels accurately, and provide additional reinforcement where needed. Overall, the different components of steel frame formwork work together to create a robust and reliable system for concrete construction. The combination of panels, connecting pins, wedges, props, braces, and accessories ensures a strong and stable formwork structure that can withstand the pressures and forces exerted during the concrete pouring process.

- Q: What are the different types of supports used with steel frame formwork?

- Construction projects utilize various types of supports in conjunction with steel frame formwork. These supports play a crucial role in establishing stability and facilitating the formwork system's ability to bear the weight and pressure generated by the poured concrete. 1. One type of support, known as adjustable steel props, consists of vertical supports that can be modified to different heights using threaded rods. These props are commonly employed alongside steel frames to reinforce horizontal beams or slabs. 2. Another support option is steel shoring systems, which encompass vertical steel tubes equipped with adjustable steel beams or U-heads at their upper ends. These systems are utilized to bolster large slabs or beams during construction. 3. Scaffolding can also serve as supports for steel frame formwork. It furnishes a stable working platform for workers and can be effortlessly adjusted to varying heights. 4. Timber or plywood bracing is sometimes employed to provide supplementary support to steel frame formwork. These bracings are placed diagonally or horizontally between the steel frames to enhance stability. 5. Hydraulic jacks are another resource that can furnish temporary support to steel frame formwork. These jacks are adjustable and can be used to elevate or lower the formwork as required. It is important to note that the selection of supports hinges upon the specific requirements of the construction project, encompassing factors such as the structure's size and shape, the weight of the poured concrete, and the height of the formwork system. The design and installation of these supports should be entrusted to experienced professionals to ensure safety and structural integrity.

- Q: Can steel frame formwork be used for both straight and sloped structures?

- Yes, steel frame formwork can be used for both straight and sloped structures. The versatility and strength of steel make it suitable for various construction projects, allowing for flexibility in forming both straight and sloped surfaces.

- Q: Can steel frame formwork be used in areas with limited natural light?

- Yes, steel frame formwork can be used in areas with limited natural light. Unlike traditional timber formwork, steel frame formwork is a rigid and durable system that can withstand various environmental conditions. It does not rely on natural light for its structural integrity or functionality. Therefore, it can be used effectively in areas with limited natural light, such as underground construction projects or enclosed spaces.

- Q: How does steel frame formwork handle different types of concrete curing techniques?

- Versatile and durable, steel frame formwork effectively manages a range of concrete curing methods. This system's stability and strength enable it to withstand the pressure and weight of the curing process. An example of a common curing technique is the traditional wet method. The steel frame formwork offers a secure and robust structure, ensuring the wet concrete retains its shape and does not deform or collapse during curing. Moreover, the frame helps regulate temperature and moisture levels, promoting optimal curing conditions. Another technique involves using curing compounds or membranes. These substances are applied to the concrete's surface to prevent moisture loss and facilitate proper curing. Steel frame formwork accommodates this method by providing a smooth and even surface for applying the compounds or membranes. It acts as a barrier, safeguarding against seepage into the ground and damage during curing. Furthermore, steel frame formwork is compatible with various accelerated curing techniques. These methods involve applying heat or other external factors to expedite the curing process. The steel frame can endure high temperatures, offering a stable structure for the concrete during accelerated curing. This ensures uniform and efficient curing, resulting in a sturdy and durable end product. In conclusion, steel frame formwork is designed to handle diverse concrete curing techniques. Its strength and stability enable it to support the weight and pressure of wet concrete during curing. Additionally, the formwork provides a smooth surface for applying curing compounds or membranes and can withstand the high temperatures associated with accelerated curing. All in all, steel frame formwork is a reliable choice for accommodating various concrete curing techniques.

- Q: How does steel frame formwork help in achieving a smooth concrete finish?

- Achieving a smooth concrete finish is made possible with the use of steel frame formwork. This formwork system provides a sturdy and stable structure for pouring the concrete, preventing any sagging or bulging. It ensures that the concrete retains its desired shape and surface finish. The formwork is constructed from top-notch steel, renowned for its strength and durability. This guarantees that it can withstand the pressure exerted by the wet concrete without bending or distorting. Consequently, the concrete sets evenly and smoothly, minimizing any imperfections or irregularities on the surface. Moreover, the steel frame formwork system allows for precise control over concrete placement and compaction. The formwork can be adjusted and aligned to the desired dimensions and angles, ensuring accurate pouring. This eliminates the need for excessive manual finishing or leveling, resulting in a smoother and more consistent finish. Furthermore, the steel frame formwork also minimizes the risk of formwork marks or imprints on the concrete surface. The steel panels used in the formwork are smooth and non-porous, reducing the chances of any texture or pattern transferring onto the concrete. This ensures a clean and uniform appearance of the finished concrete. In conclusion, steel frame formwork is essential for achieving a smooth concrete finish. It provides stability, precision, and minimizes the risk of formwork marks. Its strength, durability, and versatility make it an ideal choice for ensuring high-quality finishes in concrete construction projects.

- Q: Can steel frame formwork be used for both small and large scale construction projects?

- Yes, steel frame formwork can be used for both small and large scale construction projects. Its versatility and strength make it suitable for various project sizes and complexities. Steel frame formwork offers durability and stability, ensuring efficient and reliable concrete construction across different scales.

- Q: Are there any specific considerations for using steel frame formwork in projects with corrosive environments?

- Yes, there are specific considerations for using steel frame formwork in projects with corrosive environments. Steel, being susceptible to corrosion, needs to be protected from the corrosive elements present in the environment. This can be achieved by applying appropriate protective coatings or using corrosion-resistant materials such as stainless steel or galvanized steel. Regular maintenance and inspection are also crucial to identify and address any signs of corrosion, ensuring the longevity and safety of the steel frame formwork in corrosive environments.

Send your message to us

Scaffolding Screw Jack Formwork Scaffolding China Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches