LOG-90S8 injection molding machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 3751-6340 g

Clamping Force: 11000 kn

Opening Stroke: 1150 mm

Power(W): 45+45 kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Screw Diameter: 100-110-120-130 mm

Space between Tie Bar: 1150*1100

Ejector stroke: 350mm

Ejector force: 270 kn

Oil Tank Capacity: 2300L

S8 series Rexroth servo motor energy-saving machine

S8 Series features

Hydraulic closed loop and motor speed closed loop is realized by control system with the features of high repetition, high linearity, high efficency , and long service life. High-rigidity template design with T shot and ordinary threaded hole facilitates the mold installation. Oil filter equipment of high performance and high precision can keep the grease within NAS8. Colored control system is adopted.

SPECIFICATION OF LOG 90 S8 CRATE INJECTION MODLING MACHINE

LOG-90S8 | ||||

International size rating | 275/90 | |||

INJECTION | A | B | C | |

Shot volume | cm3 | 113 | 154 | 181 |

Shot weight | G | 106 | 144 | 170 |

OZ | 3.7 | 5.1 | 5.9 | |

Screw diameter | mm | 30 | 35 | 38 |

Injection pressure | mpa | 243 | 179 | 152 |

Screw L:D ration | 20:1 | 20:1 | 18:1 | |

Screw stroke | mm | 160 | ||

Screw speed(stepless) | r/min | 0-180 | ||

CLAMPING UNIT | ||||

Clamping force | kn | 900 | ||

Opening stroke | mm | 320 | ||

Platen size | mm×mm | 540×540 | ||

Space between fie bars | mm×mm | 360×360 | ||

Mold fhickness(Min-Max) | mm | 150-360 | ||

Max.daylingt | mm | 680 | ||

Hydraulic ejection stroke | mm | 100 | ||

Hydraulic ejection force | kn | 31 | ||

POWER UNIT | ||||

Hydraulic system pressure | mpa | 16 | ||

Max.motor current | A | 38 | ||

Heating capacity | kw | 6.5 | ||

Number of femp confrol zones | \ | 3+ nozzle | ||

GENERRL | ||||

Dry-cycle fime | Sec | 1.1 | ||

Oil fank capacify | λ | 160 | ||

Machine dimensions | m×m×m | 4.5×1.1×1.7 | ||

Machine weight | kg | 3500 | ||

Product range:90ton----2200ton

Engry saving machine with servo system

PVC special

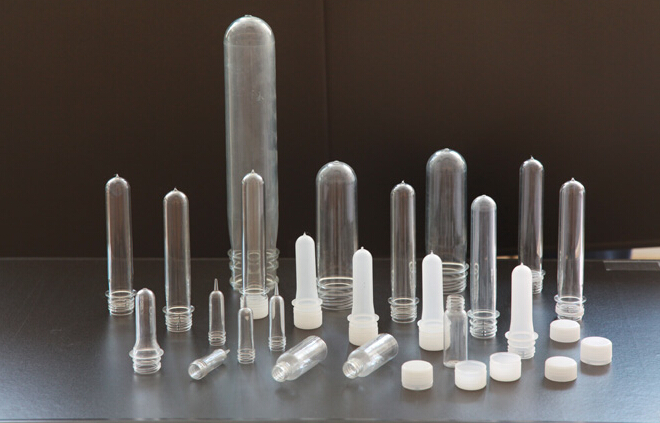

PET special

Energy Saving

Servo energy-saving injection molding machine ,there is no extra energy consumption due to output volume changes according to load.the cooling motor doesn't work and consumes no energy ,Servo energy-saving injection molding machines will save 20%-80% energy and bring you.

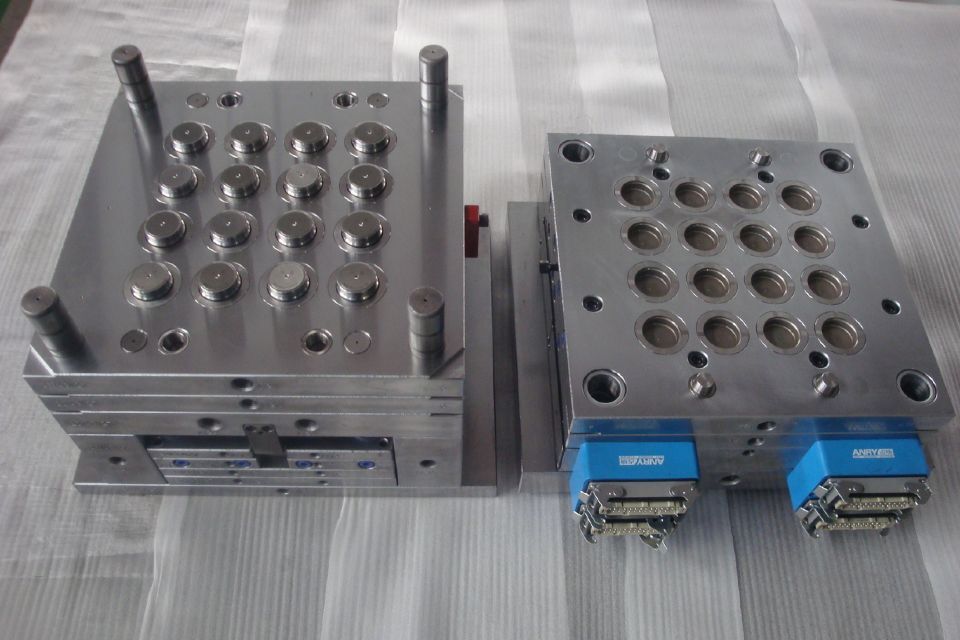

product mold

Packing detial:according to customer requirments

Delivery detial: 15-30days

- Q: Can carbon fiber be used for injection molding?

- Carbon fiber can be used for injection molding, and the typical product is CF+PPS.Carbon fibers are difficult to process two times, such as drilling on molded products, plain drills, drilling holes, and drilling bits. Therefore, in the part design to avoid two machining. In addition, as with plastic and glass fiber, and carbon fiber after the screw injection molding machine screw wear increases, the life expectancy was shortened.Global carbon fiber technology and production are still largely in the hands of Japan and the United states. There are less than 20 countries and regions that can realize the industrialization of carbon fiber in the world. There are no more than 12 large-scale production enterprises. Japan, Dongli, Japan, Toho, USA, tektronix,Japan MITSUBISHI Li Yang is the global carbon fiber production capacity of the top four manufacturers, the four respectively accounted for global carbon fiber production capacity of 23.4%, 17.1%, 14.3% and 10.3%, while Chinese enterprises accounted for only 4.3%.The global carbon fiber production is mainly based on PAN based carbon fiber. In 2009, PAN based carbon fiber production capacity accounted for about 96% of the total carbon fiber production capacity of the world. The Dongli of Japan, and Toho MITSUBISHI rayon is mainly engaged in the small tow (24K) PAN based.CF+PPS 160000 yuan / tonFiber production, in 2009 this three accounted for 70.5% of the world's small tow capacity; the United States Zoltek is mainly engaged in large tow (>24K) PAN based carbon fiber production, 2009 Zoltek accounted for the global total capacity of 49.1% large tow.

- Q: Haitian, Zhen Gong, MITSUBISHI, Sumitomo, Bo Chuang, Tai Ji, etc., what is the difference between direct press and curved arm?!

- According to the arrangement of injection device and mould locking device, they can be divided into vertical type, horizontal type and vertical horizontal compound type. The mold of the injection machine can be fixed in horizontal or vertical position. Most machines are horizontal, vertical machines are used for some special applications, and the machines are inserted by gravity.

- Q: What kinds of lubricants are used in the injection molding machine?

- No.Two, more impurities, especially the ultra small impurities, third, due to high temperature friction factors such as coke smell, currently on the market is not a good way to solve these micro impurities, water, emulsion, coke.So everyone thinks it's gone bad. It needs to be replaced. It's also for the maintenance of the equipment.Here, we will analyze the quality index of lubricating oil:1, viscosity: the most important point, in fact, this problem generally does not need to consider, almost all of the injection molding factory for oil viscosity is qualified, 5-8 years will not change.2, the impurity much, especially those of ultrafine particles of impurities, suspended in lubricating oil, lubricating oil to feel dirty, and more, this is a big problem, but it can solve, behind our discussion3, moisture: it is also a big problem, more than impurities, there are emulsified parts, there are free parts, discussed later4, partial acid: corrosion, sealing ring, etc., difficult to solve, but can be prevented, as long as the lubricant used to ensure that the temperature at ordinary temperatures below 50 degrees, there is no moisture, can be avoided4, pour point, freezing point, lightning: basic in injection molding die casting equipment such as oil, without too much consideration.5, additives: nothing more than anti-wear additives, antioxidants, anti foaming agents, anti emulsifier, etc., in general, additives will continue to wear and tear, but in general circumstances can be used for at least 5-8 years.Other seems to be nothing, and the above point of view, it is not difficult to analyze, as long as the removal of ultra-fine impurities, emulsification, moisture, oil can continue to use for 5-8 years.stay

- Q: How to debug the injection molding machine? solve

- This is not to say the machine belongs to the high current working machine but also large machine should have a master in their own training proficient is best not to touch.

- Q: What is the function of the temperature control box of the injection molding machine? Thank you

- Controlling the temperature of two heating tubes.Chasing the answerThe temperature is too high and too low, the thermostat plays the role of switch heating tube power supply.The heating tube is used to warm the mold

- Q: I want to study and maintain the injection molding machine, but I don't know whether it's difficult or not. What are the main points I should pay attention to when I study?

- Both imported and domestic injection molding machines have the following characteristics:And representatives of Jingxian County rubber hose enterprises attended the meeting. Mayor Gao Hongzhi attended the seminar and delivered a speech. Jingxian County is the birthplace of plastic pipe industry, great opportunities in recent years the county seize cars, coal, metallurgy, petroleum and other industries of China's rapid development, focusing on creating the first industry, the strongest and most characteristic industry, the author probes into many aspects of process principle, process flow, process, reaction the mechanism, adverse reaction and prevention and control measures, equipment, Manning, cost estimation, environmental protection, technical characteristics, product quality standards, can be used for domestic automotive hose technology reference to the development of this report;Oil or electric compound or local electric injection molding machine. Whether all electric or hybrid type belong to the category of electric injection molding machine injection molding machine, therefore, since the development of the plastic injection machine is all electric or electric part (hybrid) has aroused extensive discussion. More than the "full electrification" of the injection molding machine, especially the feeding structure, which is driven by an electric servo motor, is very common in injection molding machines in Germany and italy.

- Q: What do you mean by the number of beers produced by an injection molding machine?

- In general, each beer refers to the injection molding machine after a molding, take out products (including nozzles and products). If it is 1*1 hole number, a beer product =1 products; if it is 1*2 hole number, then a beer =2 products, and so on, and so on.And if it is two-color machine, then the molding is two times after a beer, the other is the same.

- Q: when the material stored, the screw has been in situ, and will not go back to the set stop position. What shall I do?

- The storage pressure is too small2. back pressure is too large, leading to the screw can not relax3. hydraulic system pressure relief4. melt temperature is too low5., melt motor power is too small, or the motor pressure is serious.6. screw barrel and raw materials do not match7., the material is not normal?More injection molding machine screw knowledge inquiries, Baidu search: "Jin Xin * screw", "Shenzhen Jin Xin * screw" for you to answer! Hope to adopt!

- Q: How the elite injection molding machine sales in Southern China?

- Not how the elite injection molding machine is low, I used, not very easy to use. The quality is poor and the price is cheap

- Q: What are the injection molding machine brands in China?

- Factors affecting user purchasesIndustry trends in the purchase of injection molding machines by users5, the survey of purchasing plan shows that 51% of users have purchasing plan. Among them, foreign-funded enterprises accounted for 40%, private enterprises accounted for 30%, joint-stock enterprises more than 20%, while state-owned enterprises less than 10%. Most of these users of the purchase plan belong to the automotive industry, followed by the packaging and electronic communications equipment industry.6, when asked whether the user will buy again in the use of brand, 36% of users are positive, 14% of users clearly will not, 50% of users expressed uncertainty.That is, the number of respondents surveyed and many factors such as uneven distribution of trade restrictions, although the investigation has a certain objectivity, but can not fully reflect the real situation of the market, only for your reference.

Send your message to us

LOG-90S8 injection molding machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords