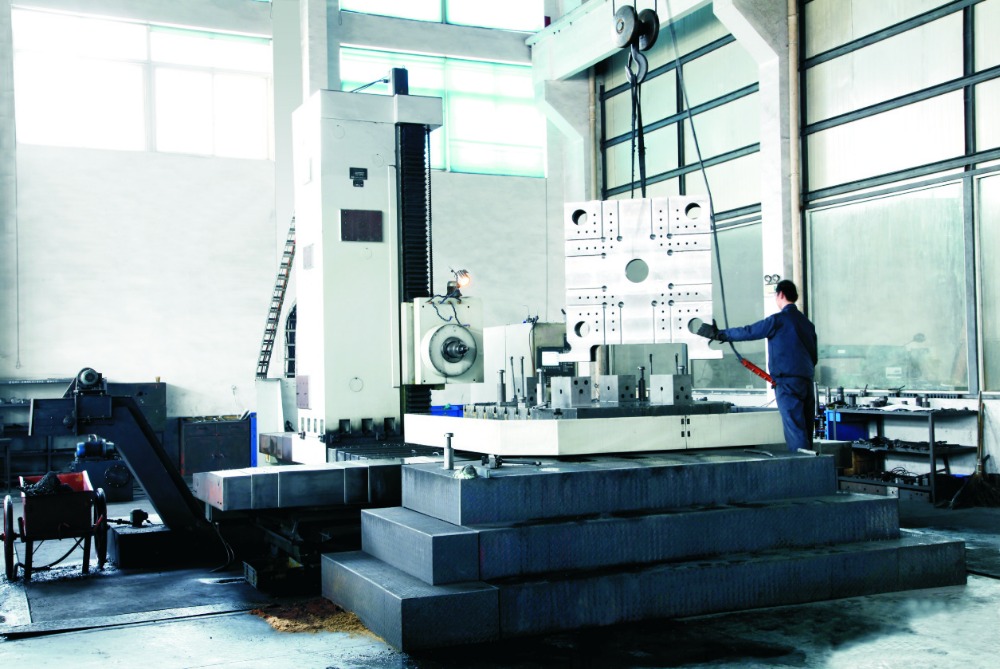

Injection molding machine LOG-900S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Condition: New

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG 900S8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Clamping Force: 9000kn

Power(W): 37+37

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Delivery Detail: | 60 DAYS |

|---|

| Description | Unit | LOG-900S8 | |||

| international recognized models | |||||

| injection | B | C | D | ||

| Tjeoretical injection volume | cm³ | 3179 | 3825 | 4750 | 5652 |

| Shot volume | g | 2893 | 3571 | 4321 | 5143 |

| Oz | 102.5 | 12.6 | 153 | 182.1 | |

| Screw diameter | mm | 90 | 100 | 110 | 120 |

| Injection diameter | mpa | 227 | 184 | 152 | 128 |

| Screw L:D ratio | 24.4:1 | 22:01 | 20:01 | 18.3:1 | |

| Scerw steoke | mm | 500 | |||

| Screw rotate speed | r/min | 0-120 | |||

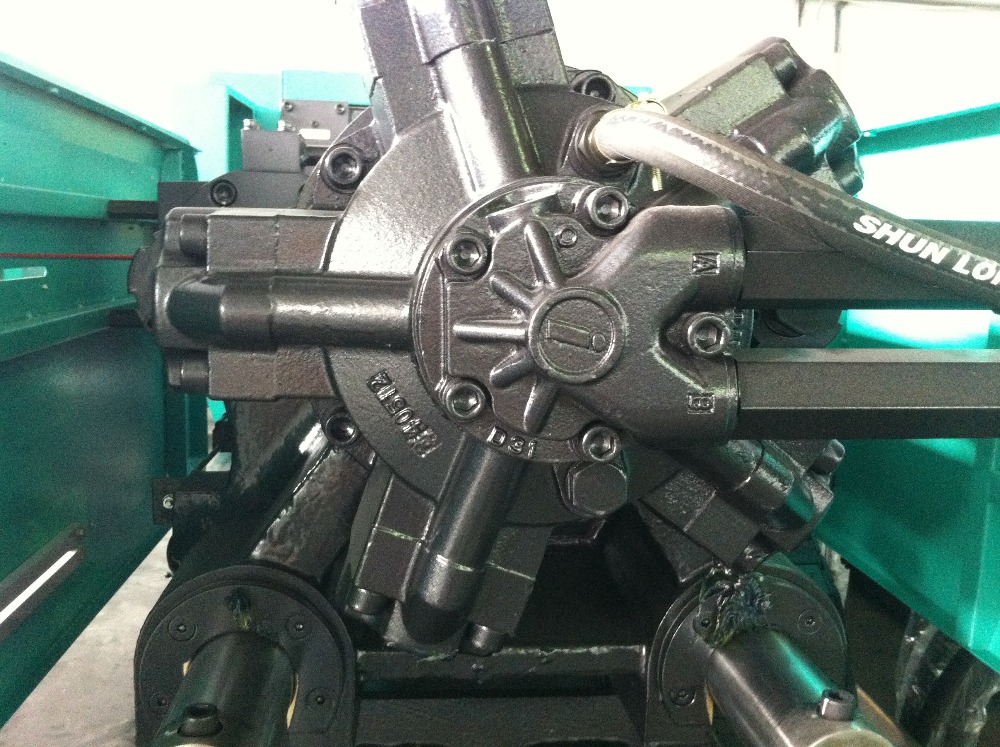

| CLAMPING UNIT | |||||

| Clamping force | kN | 9000 | |||

| Opening stroke | mm | 1050 | |||

| Platen size | mm*mm | 1530*1530 | |||

| Space between tie bars | mm*mm | 1080*1030 | |||

| Maldthickness | mm | 400-1100 | |||

| Platen Mix stroke | mm | 2150 | |||

| Ejection stroke | mm | 300 | |||

| Ejcetion force | kN | 270 | |||

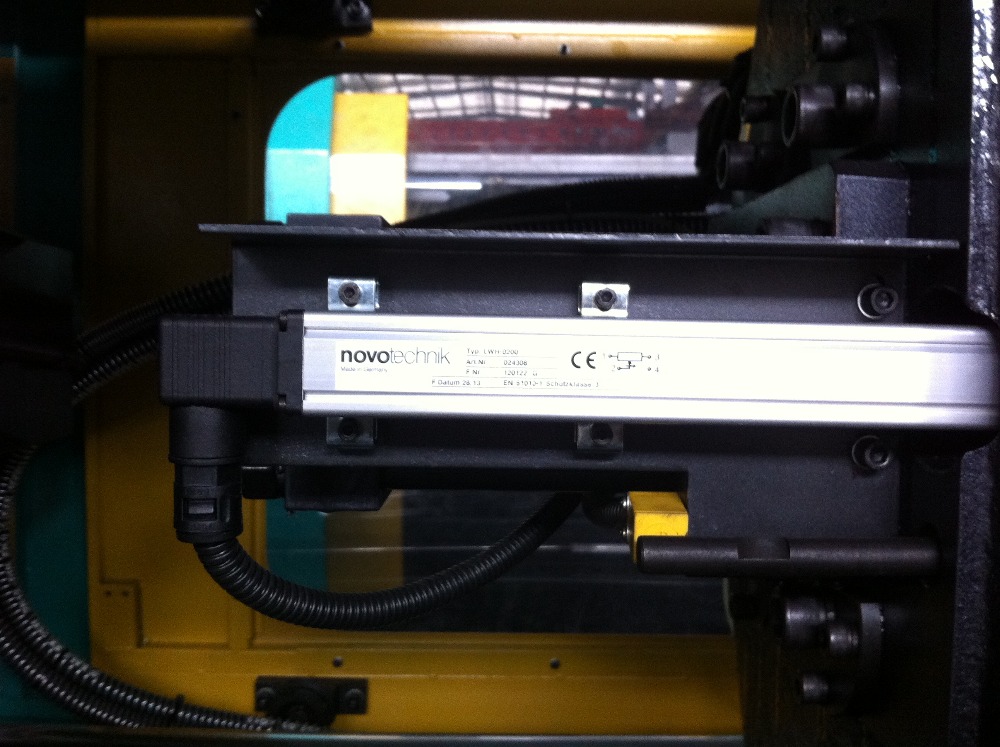

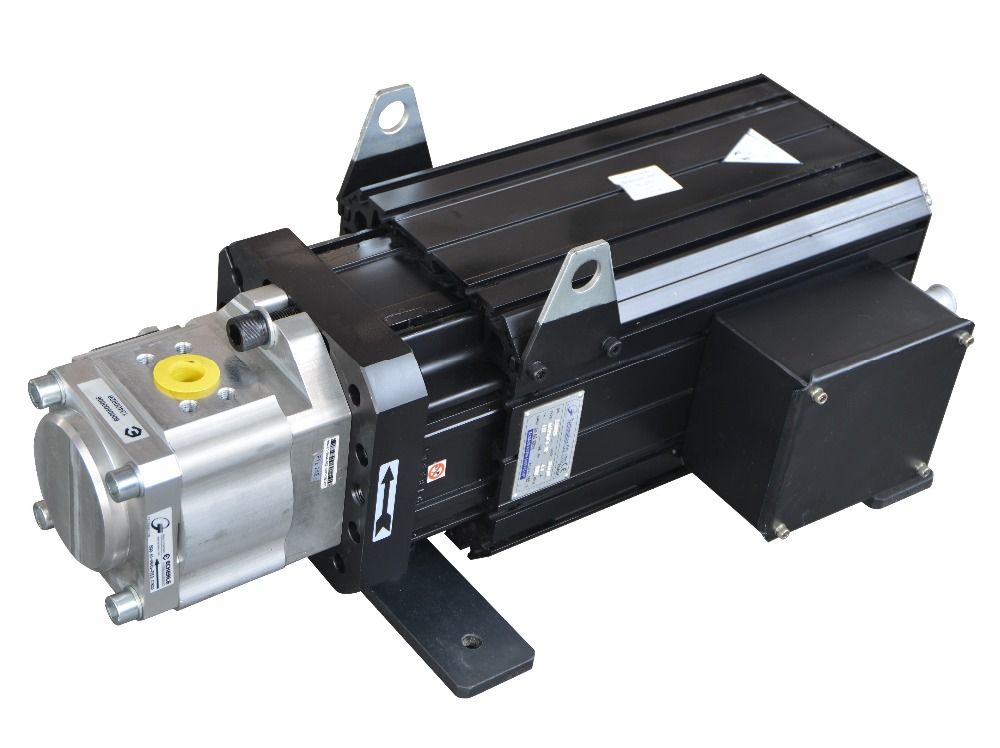

| Power/Elcetric Heating | |||||

| Hydralic system pressure | Mpa | 17.5 | |||

| Pump motor | kw | 37+37 | |||

| Heating power | kw | 52.45 | |||

| Number of temp.conteol | 6+nozzle | ||||

| Other | |||||

| Cycle time | sec | 8 | |||

| Tank volume | L | 1900 | |||

| Machine dimesions | m*m*m | 11*2.4*3.1 | |||

| Weight of machine | kg | 48000 | |||

- Q: Can carbon fiber be used for injection molding?

- Carbon fiber can be used for injection molding, and the typical product is CF+PPS.Carbon fibers are difficult to process two times, such as drilling on molded products, plain drills, drilling holes, and drilling bits. Therefore, in the part design to avoid two machining. In addition, as with plastic and glass fiber, and carbon fiber after the screw injection molding machine screw wear increases, the life expectancy was shortened.Global carbon fiber technology and production are still largely in the hands of Japan and the United states. There are less than 20 countries and regions that can realize the industrialization of carbon fiber in the world. There are no more than 12 large-scale production enterprises. Japan, Dongli, Japan, Toho, USA, tektronix,Japan MITSUBISHI Li Yang is the global carbon fiber production capacity of the top four manufacturers, the four respectively accounted for global carbon fiber production capacity of 23.4%, 17.1%, 14.3% and 10.3%, while Chinese enterprises accounted for only 4.3%.The global carbon fiber production is mainly based on PAN based carbon fiber. In 2009, PAN based carbon fiber production capacity accounted for about 96% of the total carbon fiber production capacity of the world. The Dongli of Japan, and Toho MITSUBISHI rayon is mainly engaged in the small tow (24K) PAN based.CF+PPS 160000 yuan / tonFiber production, in 2009 this three accounted for 70.5% of the world's small tow capacity; the United States Zoltek is mainly engaged in large tow (>24K) PAN based carbon fiber production, 2009 Zoltek accounted for the global total capacity of 49.1% large tow.

- Q: What does injection pressure mean?

- Five, the adjustment of back pressureThe adjustment of the injection back pressure shall be determined according to the raw material performance, drying conditions, product structure and quality, and the back pressure should be adjusted at 3-15kg/cm 3. When the surface of the product has little Qihua, mixed color, shrink and product size and weight changes, may be appropriate to increase the back pressure. When the nozzle leakage glue, salivation, Melt Overheating product decomposition, discoloration and feeding back too slow may be considered appropriate to reduce the back pressure.Back pressure is one of the important parameters to control melt quality and product quality in injection molding process. Proper back pressure plays an important role in improving product quality, and can not be ignored!

- Q: For example, for nylon 6 GF30 material, some injection process information required to set the injection pressure is: 85-100MPa, the actual adjustment of the machine in our injection molding machine panel set the injection pressure is 65, then this number "65" unit is what?If the number of units is "bar", not with the data of some books conflict, please expert answer

- 1MPa=10bar 10KN=1T here are not in conflict, in the injection molding machine test machine computer interface on the back of the unit is 65 bar, we usually say the clamping force is in tonnes,

- Q: From left to right nozzle middle feeding end. Someone told me that the temperature setting should high temperature to low temperature, such as from the nozzle 230220210200. Start is not so ah. Who knows what "nylon 6" as an example to say thank you.

- But if the injection amount is far lower than the theoretical amount of about 80%, due to the homogeneous material is very small, so reduce the temperature to prevent the material plastication decomposition was from low to high temperature Nylon 6 crystal plastic. Its heating temperature starts at the feed port. 240~260270~290 270~280280~290. The machine also varies. I hope it can help you

- Q: Known diameter and displacement length of screw.

- The calculated volume of PS is L (L)Two, quality words1. when injection molded products are manufactured in PS:M (PS) = (1.1~1.3) * (product weight + gating system total weight)The correction factor in parentheses is the higher the product quality, the greater the value2.

- Q: What kind of metal material is the nozzle head of injection molding machine?

- The injection head of the injection machine is the material of No. 45 steelNozzle specifications must be confirmed: total length, diameter of tooth, distance between teeth.All kinds of nozzles, spring nozzles and split nozzles for injection molding machinesThe thread has M18*2.5,M22*2,M24*2, M24*2 lengthenedM30*2, M30*2 lengthenedM30*3, M30*3 lengthenedM36*2, M36*2 lengthened,M36*3, M36*3 lengthenedM39*2, M39*2 extended specialtyM39*3, M39*3 lengthened special skillsM42*3, lengthenM45*2And so on all kinds of specifications, various length sizes. Special specifications must be ordered ~ systemThe difference between a split nozzle and a spring nozzle

- Q: Recommend durable low pressure injection molding machines?

- Low pressure injection molding machine Dongguan tiansai Plastic Machinery Co., Ltd. has CE certification, spare parts production, stable quality, electronic components are selected GB or imported brands, and the company in accordance with ISO9001 and TS16949 quality management system, in addition to standard injection molding equipment can also be customized equipment, and the 1 year warranty. (refer to the website www.lpms of Dongguan Tian Jie plastics machinery Co., Ltd.)

- Q: Not transformer. It's wires and meters. Because the transformer is public. If 10 kilowatts is not enough. How much is enough?

- 160T injection molding machine, if you want to use electromagnetic heating control panels for energy-saving transformation, the easiest way is to determine the original electric heating block is a few areas? What is the power of each zone? Then, in accordance with this to match the line, a few zones with several electromagnetic heating control panels, the power of each board and the power of the same heat block, or close to the line. In this way, the power saving rate can reach more than 40%, and the production efficiency can also be improved by about 20%. The friend in need can find Xin Rui energy saving manager, consult the order, and have professional technical guidance!

- Q: What is low voltage protection (injection molding machine)?

- Protect the mold. Never press dies during production

- Q: What is the meaning of injection molding machine before melting and pumping and after melting? What's the function of 10?

- Before the pumping molten refers to the pumping action in the melt before the start, to remove the injection pressure in the cylinder head, the buildup of pressure; pumping molten refers to the pumping action in the melt after the end to relieved some of the pressure generated by the melt.The pumping action is not necessary, generally set according to the nature of raw materials, no salivation phenomenon is not used.

Send your message to us

Injection molding machine LOG-900S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords