Injection Molding Machine LOG-130S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Preform Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG130-A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 196g-239g-277g

Clamping Force: 1300KN

Opening Stroke: 380mm

Power(W): 11 Kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Name: PET Preform

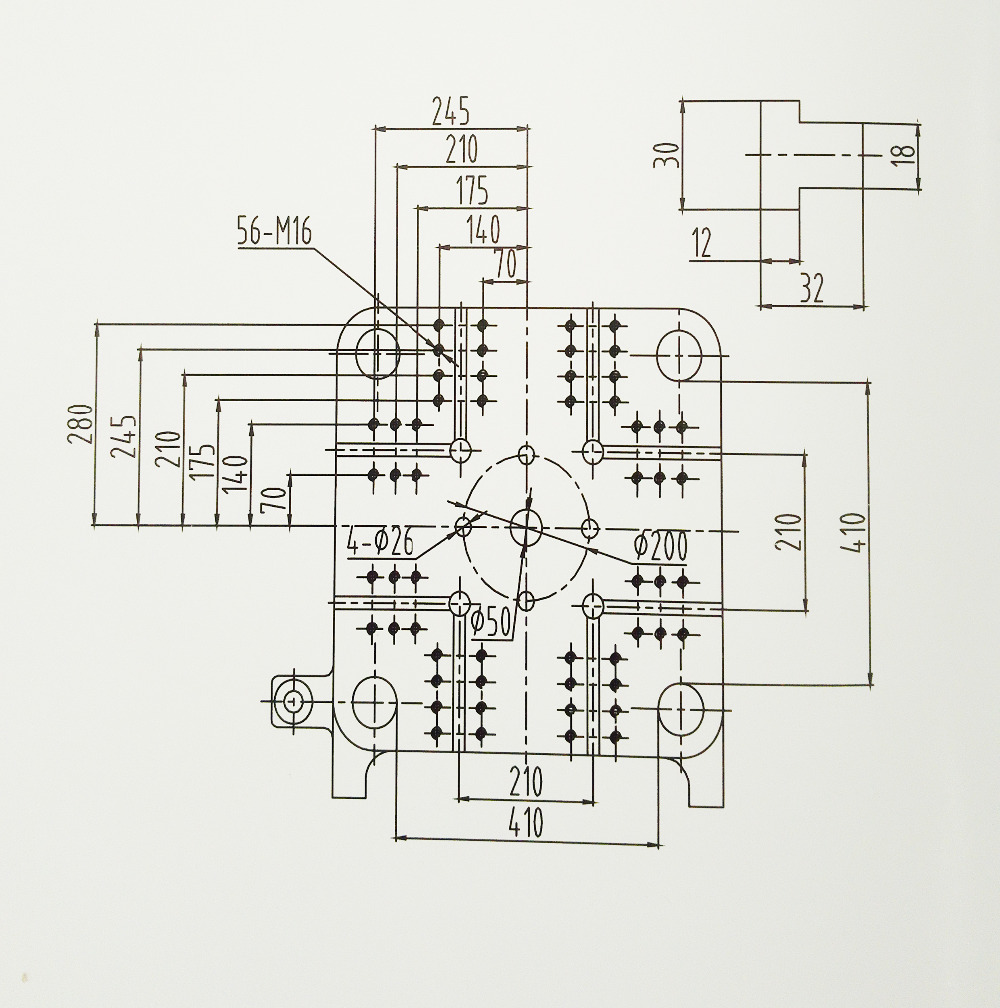

Space between tie bar: 410mm*410mm

Color: Green

Machine weight: 4T

Screw Diameter: 38-45mm

Machine dimension(L*W*H): 4.6*1.2*1.8

Warranty: 1 Year

Material: Stainless Steel

Machine: Thermoplastic Injection Moulding Machine

| Description | Unit | LOG-130A8 | ||

| international recognized models | 416/130 | |||

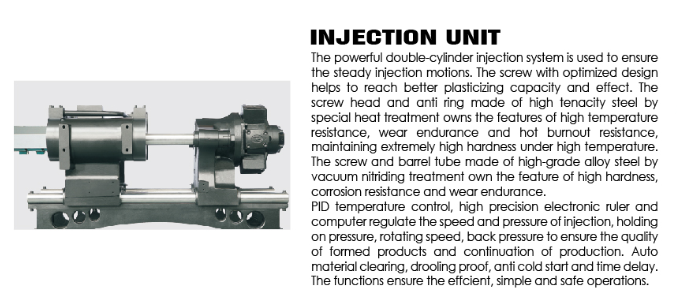

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 215 | 263 | 302 |

| Shot volume | g | 196 | 239 | 274 |

| Oz | 6.9 | 8.4 | 9.6 | |

| Screw diameter | mm | 38 | 42 | 45 |

| Injection diameter | mpa | 193 | 158 | 138 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| Scerw steoke | mm | 190 | ||

| Screw rotate speed | r/min | 180 | ||

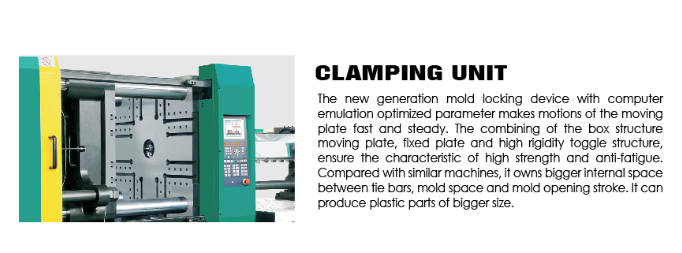

| CLAMPING UNIT | ||||

| Clamping force | kN | 1300 | ||

| Opening stroke | mm | 380 | ||

| Platen size | mm*mm | 610*610 | ||

| Space between tie bars | mm*mm | 410*410 | ||

| Maldthickness | mm | 150-430 | ||

| Platen Mix stroke | mm | 810 | ||

| Ejection stroke | mm | 120 | ||

| Ejcetion force | kN | 42 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 12 | ||

| Heating power | kw | 7.7 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 1.3 | ||

| Tank volume | L | 200 | ||

| Machine dimesions | m*m*m | 4.6*1.2*1.8 | ||

| Weight of machine | kg | 4000 | ||

Packaging Details: 20 GPcabinet Delivery

Delivery Detail: two weeks after get payment

| INJECTION | LOG130 | |||

| A | B | C | ||

| Shot volume | cm³ | 215 | 263 | 302 |

| Shot weight (ps) | G | 196 | 239 | 274 |

| oz | 7 | 8 | 10 | |

| Max injection rate | cm³/s | 97 | 118 | 163 |

| Screw diameter | mm | 38 | 42 | 45 |

| Plasticizing rate | Kg/h | 46 | 60 | 75 |

| Injection pressure | Mpa | 193 | 158 | 138 |

| Screw L:D ratio | 22:01 | 20:01 | 18:01 | |

| screw speed | r/min | 0~180 | ||

| CLAMPING | ||||

| Clamping force | Kn | 1300 | ||

| Opening stroke | mm | 380 | ||

| Platen size | mm*mm | 610*610 | ||

| Space between tie bars | mm*mm | 410*410 | ||

| Mold thickness (Min--Max) | mm | 150~430 | ||

| Hydraulic ejection stroke | mm | 120 | ||

| Hydraulic ejection force | Kn | 42 | ||

| Power Unit | ||||

| Hydraulic system pressure | Mpa | 17.5 | ||

| Pump motor | Kw | 11 | ||

| Heating capacity | Kw | 7.7 | ||

| Number of temp control zones | 4+ (nozzle) | |||

| GENERAL | ||||

| Dry-cycle time | sec | 1.3 | ||

| oil tank capacity | L | 200 | ||

| Machine dimensions | m*m*m | 4.6*1.2*1.8 | ||

| Machine weight | kg | 3550 | ||

Platen Dimensions:

product 1

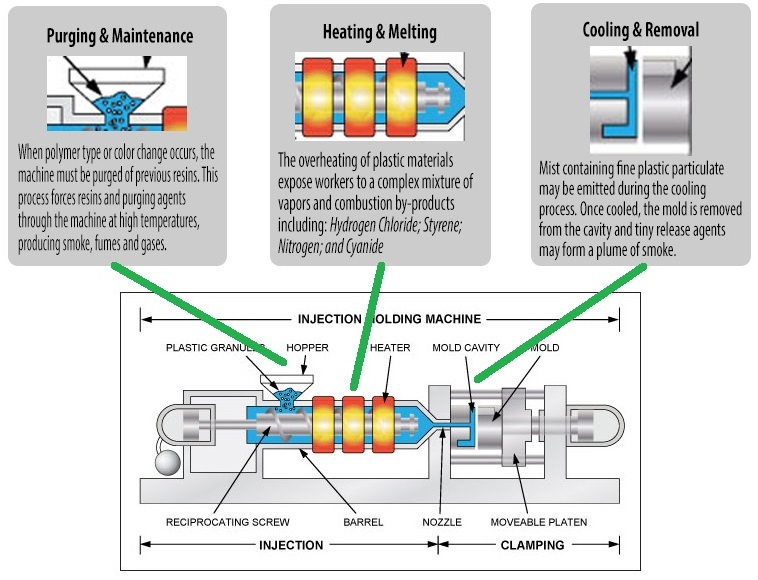

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

- Q: What kind of lubricant does the injection machine use?

- The main use of antiwear hydraulic oil, as well as 00-000, extreme pressure grease

- Q: injection molding machine is used, every day is 20000G 10000G 7000G of 6000G 4000G 2000G 1000G 560G 210G why the type of injection machine to overcome the number of markers. For example, 20000G injection molding machine can be injected products of the quality of the largest and minimum number of kilograms, thank you

- Injection volume, that is, the screw material capacity and the maximum injection volume at one time. 20000G is 20 kilograms, the image of the point, the injection molding machine production of the largest, can do 20 kilograms of heavy products.

- Q: How many tons is the injection machine of 4 Ann?

- Ann is the name of Hongkong in the last century. Ann means the amount of injection, and tons, that is, clamping force. generally speaking3 Ann -----60T4 Ann -----90T7 Ann -----120T10 Ann -----160T14 Ann -----210T17 Ann -----250T

- Q: What is the temperature of the NH, H and HP on the injection machine screen?

- Injection molding machine in the lock mode, the thimble is to look back, not open mold, to see if the parameters are set incorrectly, press the mold opening, the volume of mold opening valve, there is no electricity

- Q: What should be noticed before the machine is stopped when the injection machine is finished?

- Dongguan City Zhen Ying Machinery equipment limited company to remind you: to prolong the life of the injection molding machine, usually must take good care of!

- Q: From left to right nozzle middle feeding end. Someone told me that the temperature setting should high temperature to low temperature, such as from the nozzle 230220210200. Start is not so ah. Who knows what "nylon 6" as an example to say thank you.

- The plastication temperature is higher than the melting temperature for the material, some plastics segment is low, mainly to ensure the uniform material in this temperature. The nozzle temperature is higher because its low temperature and injection mold front contact to the red hot runner. This is short of non hot runner mold. And it is about to reach the theoretical amount of injection volume 80%, from the inlet temperature is low, high, slightly lower.

- Q: Known diameter and displacement length of screw.

- when the product is other plastic:M (other) = (1.1~1.3) * (product weight + gating system total weight)M (PS) =1.05*W (other) / P (other)1.05 is PS density unit g/cm3P (other) for other plastic density(formula: P =M/V)

- Q: Please tell me the reason for choosing this tonnageFor example, an injection molding machine, water flow of 4 tons per hour, then 4 units on the election of 20T cooling tower is not enough? 20T's cooling water flow is about 18 cubic meters per hour

- The cooling water machine 160T~200T injection dosage of 160T~200T injection molding machine cooling water consumption is 4.2 m fand /H, you have 4, that is 16.8m /H this is fand regardless of your water, cold water machine, injection molding machine, mold temperature and water machine water situation. Personal advice, buy a water tower, you can buy a little larger, and if you want to increase the machine later, the water tower is small, then you have to change. At the moment, it's okay to pick a big water tower (big, cool, better, too big to waste), and 20t's water tower and 30t's water tower don't cost much (about 600~900)20t traffic to 15.62m /H fand tower25t traffic to 19.51m /H fand tower30t traffic to 23.4m /H fand tower

- Q: Introduction of injection molding machine

- Secondly, the rated power of the whole machine is only 245KW, and the energy consumption of the traditional machinery is reduced by more than 45%;Third, an injection molding capacity of more than 50KG, ranking first in the world;Fourth, injection precision control, will not produce bubbles in the injection molding, greatly improving the quality of products;Fifth, the products are widely used in industry, transportation, warehousing, packaging, building, automobile, home appliances and defense, large plastic injection products with its light weight, good elasticity, high impact resistance, good chemical stability and excellent mechanical properties, is widely replaced with steel products and wood products.

- Q: Vertical injection molding machine in the semi-automatic state, not sol, and sometimes sol is very slow, seems to be very difficult, and sometimes simply do not turn. The problem is that it occurs during normal use, so the temperature should be fine. The parameter should be OK, too. I removed the screw and cleaned it. There was no foreign object. Under manual operation, the sol is very smooth. Consult an expert.

- Mainly back pressure problems, a lot of injection molding machine, manual adhesive and automatic adhesive in the back pressure is not the same

Send your message to us

Injection Molding Machine LOG-130S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords