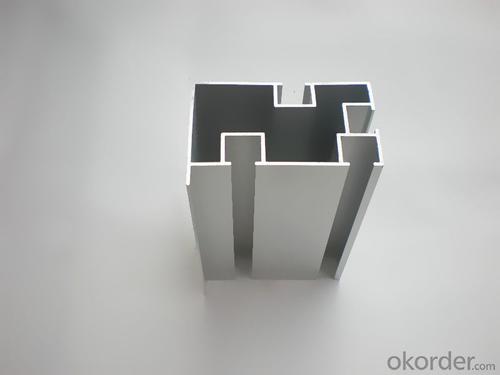

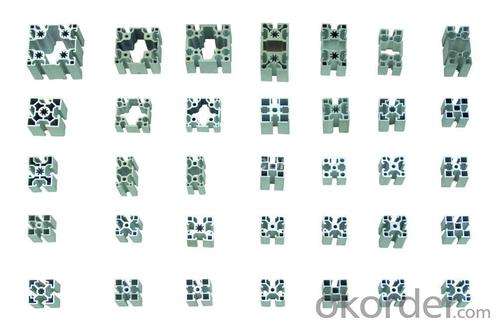

Industrial Aluminum Extrusion Profiles T-Slot

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Are aluminum profiles suitable for use in pharmaceutical manufacturing?

- Pharmaceutical manufacturing can benefit greatly from the use of aluminum profiles. These profiles offer a range of advantages in the industry due to the versatile and lightweight nature of aluminum. One crucial advantage is the corrosion resistance of aluminum profiles, which is of utmost importance in pharmaceutical manufacturing where cleanliness and hygiene are vital. Aluminum does not rust or deteriorate when exposed to moisture, making it an ideal material for cleanrooms and sterile environments. Furthermore, aluminum profiles are easy to clean and maintain, maintaining their structural integrity even after rigorous cleaning processes such as sterilization and disinfection. This ensures that the pharmaceutical manufacturing equipment remains in a pristine and contamination-free condition. Customization is another key benefit of aluminum profiles in pharmaceutical manufacturing. These profiles can be easily fabricated into various shapes and sizes, allowing for the creation of complex structures and machinery. This flexibility makes aluminum profiles an excellent choice for designing precise pharmaceutical equipment, including conveyor systems, processing machinery, and packaging equipment. Additionally, aluminum profiles possess excellent thermal conductivity, which is advantageous in pharmaceutical manufacturing processes that involve temperature control. Freeze-drying, sterilization, and granulation, for example, can benefit from efficient heat transfer provided by aluminum profiles. This ensures that pharmaceutical products are processed and stored at the desired temperature. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, reducing the carbon footprint associated with pharmaceutical manufacturing. The ability to reuse and repurpose aluminum profiles contributes to a circular economy and minimizes waste generation. In conclusion, aluminum profiles are highly suitable for pharmaceutical manufacturing. Their corrosion resistance, ease of cleaning, customization options, thermal conductivity, and sustainability make them an excellent choice for designing and fabricating pharmaceutical equipment and machinery.

- Q: Can aluminum profiles be used for creating protective enclosures?

- Yes, aluminum profiles can be used for creating protective enclosures. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various applications, including protective enclosures. Aluminum profiles can be easily fabricated and assembled to create custom enclosures of different shapes and sizes. They provide excellent structural integrity and can withstand harsh environmental conditions. Additionally, aluminum profiles offer good thermal conductivity, allowing for efficient heat dissipation if required. Overall, aluminum profiles are a popular choice for creating protective enclosures due to their versatility, strength, and durability.

- Q: Are aluminum profiles compatible with glass?

- Yes, aluminum profiles are compatible with glass. Aluminum frames are commonly used in the construction industry to hold and support glass panels in windows, doors, and other architectural applications. The lightweight, durable, and corrosion-resistant properties of aluminum make it an ideal material for framing glass.

- Q: Can aluminum profiles be utilized in constructing building facades that necessitate superior thermal insulation?

- <p>Yes, aluminum profiles can be used for building facades requiring high levels of insulation. By incorporating thermal breaks or using insulated aluminum profiles, the thermal conductivity of aluminum can be mitigated. These profiles can also be combined with insulating materials like polyurethane or mineral wool to enhance the insulation properties. Modern facade systems often employ aluminum due to its strength, durability, and design flexibility, while ensuring energy efficiency through advanced insulation techniques.</p>

- Q: Is it possible to utilize aluminum profiles in the construction of residential buildings or homes?

- <p>Yes, aluminum profiles can be used in residential buildings and houses. They are valued for their durability, low maintenance, and resistance to corrosion. Aluminum profiles are commonly used in window frames, door frames, and as structural components due to their strength and lightweight properties. They also offer good thermal insulation and can be easily painted or finished to match the aesthetic of the building.</p>

- Q: Is it possible to utilize aluminum profiles as a material for flooring?

- <p>Yes, aluminum profiles can be used for flooring, particularly in industrial or commercial settings where durability and resistance to wear are required. They are known for their strength, lightweight, and corrosion resistance, making them suitable for high-traffic areas. Aluminum profiles can be used to create grid systems or as support structures for modular flooring solutions. However, they are not typically used as the direct surface material for flooring due to their hardness and potential for thermal conductivity, which can make them uncomfortable underfoot. Instead, they are often part of a system that supports other flooring materials like tiles or planks.</p>

- Q: What is aluminum profile opening mold, I want to process a batch of aluminum profiles, the other side to open mold fees also expensive, then I can open the mold of things? I don't know the hero for a favor

- There is no on-site mold, so the mold must be re opened to meet the requirements. I hope my answer can help you. Thanks

- Q: Can aluminum profiles be used in modular exhibition system manufacturing?

- Yes, aluminum profiles can be used in modular exhibition system manufacturing. Aluminum profiles are known for their lightweight and durable properties, making them ideal for constructing modular exhibition systems. They are easy to handle and assemble, allowing for quick and efficient installation and dismantling of exhibition booths. Additionally, aluminum profiles can be easily customized and reconfigured to meet specific design requirements, making them a versatile choice for modular exhibition system manufacturing.

- Q: What are the bending capabilities of aluminum profiles?

- Aluminum profiles have excellent bending capabilities due to their malleability and ductility. They can be easily formed into various shapes and angles, making them versatile for a wide range of applications. However, the specific bending capabilities may vary depending on the alloy and temper of the aluminum profile.

- Q: Are aluminum profiles suitable for exhibition displays?

- Yes, aluminum profiles are highly suitable for exhibition displays. They are lightweight, durable, and can be easily customized to fit various display requirements. Aluminum profiles also offer a sleek and modern aesthetic, making them ideal for creating visually appealing exhibition displays. Additionally, they are versatile and can be easily assembled and disassembled, allowing for easy transportation and setup at different exhibition venues.

Send your message to us

Industrial Aluminum Extrusion Profiles T-Slot

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords