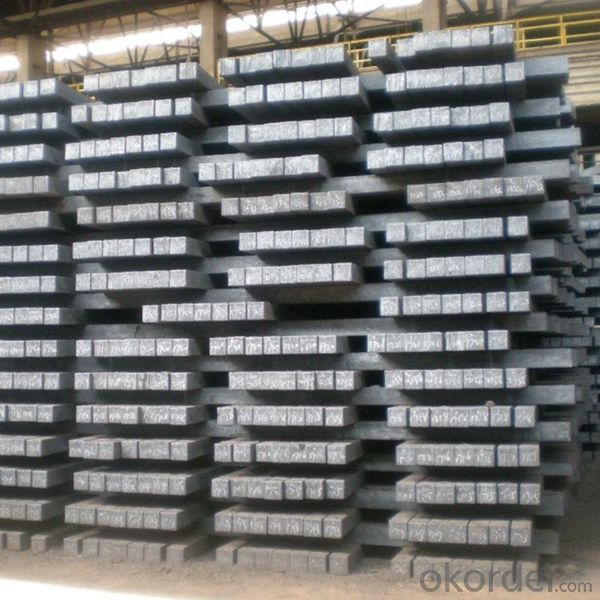

Hot Rolled Steel Billet China Supplier/Made In China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product picture:

2. Production Equipment

Currently the main equipment:

1, two section of new environmental protection gas occurrence furnace two.

2, digital temperature control of high efficiency and energy saving heating furnace.

3, 650 continuous rolling mill bearing.

4, natural cooling bed.

5, modern product collecting and bundling equipment.

6, electrical control of the use of the German Siemens products.

3. Production Description

Owing to the bearing of domestic advanced technology of continuous mill, natural cooling bed and the advanced electric control equipment, so that the company's products than water cooling products in quality are greatly improved, product size precision of the company, minus tolerance of high control precision, quality and stable performance, is not easy to rust, appearance and color pure and beautiful. And rolling speed, high output, consumption and low cost, has the very high prestige both at home and abroad.

2013 February to transform the original steel production line, the electric control system of rolling mill was updated, increased the number of rolling mill heating furnace, improves the cooling capacity, etc..

Company's annual output of 800000 tons. Main products are GB No. 10 -30 channel, American Standard Japanese standard channel and strip etc..

4. Why Choose Us?

We are professional in products export.

We have established longterm cooperation with forwarders and shipping company.

We have more than twenty overseas houseware with timely aftersale service.

We have complicate and professional quality control system, from material purchasing to products loading abroad.

- Q: How is steel forgings heat-treated for improved mechanical properties?

- Steel forgings are heat-treated through a process called quenching and tempering to enhance their mechanical properties. Initially, the steel is heated to a high temperature and then rapidly cooled, or quenched, in a liquid medium such as oil or water. This rapid cooling helps to achieve high hardness and strength in the material. Following quenching, the steel is tempered by reheating it to a lower temperature to relieve internal stresses and improve toughness while maintaining a desirable level of hardness. This heat treatment process is crucial in optimizing the mechanical properties of steel forgings, making them more durable and suitable for various applications.

- Q: What are the uses of steel grating in walkways and platforms?

- Steel grating is commonly used in walkways and platforms due to its various advantages. It provides a robust and durable surface for people to walk on, ensuring their safety. The open grid design allows for effective drainage of liquids, preventing slipping hazards. Steel grating also offers excellent load-bearing capacity, making it suitable for heavy foot traffic or equipment. Additionally, its corrosion-resistant properties make it ideal for outdoor applications, where exposure to moisture and harsh weather conditions is common. Overall, steel grating enhances the functionality and safety of walkways and platforms.

- Q: How does steel sheet metal bending and forming work?

- Steel sheet metal bending and forming work by applying force to a sheet of steel, causing it to deform and take on a desired shape. This can be achieved through various methods such as using specialized machinery or tools, like a press brake, which applies pressure to the sheet metal along a specific line to create bends or folds. The process may also involve heating the metal to make it more malleable and easier to form. Overall, steel sheet metal bending and forming require precise techniques and equipment to shape the metal into the desired final product.

- Q: Can steel be recycled? If so, how?

- Yes, steel can be recycled. The process involves collecting steel products, such as old vehicles or scrap metal, and taking them to a recycling facility. At the facility, the steel is sorted, cleaned, and shredded into small pieces. These pieces are then melted down in a furnace to remove impurities and create new steel. The recycled steel can be used to manufacture various products, reducing the need for raw materials and conserving energy.

- Q: How does steel pipe coating for underground applications work?

- Steel pipe coating for underground applications typically involves applying a protective layer to the surface of the steel pipe to prevent corrosion and extend its lifespan. This coating is usually made from materials such as epoxy, polyethylene, or polyurethane, which provide excellent resistance to moisture, chemicals, and soil conditions. The coating process involves cleaning and preparing the pipe surface, followed by the application of the coating material through methods like extrusion, spraying, or wrapping. Once the coating is applied and properly cured, it acts as a barrier, shielding the steel pipe from environmental factors and enhancing its durability in underground environments.

- Q: How are steel products used in the construction of shopping malls and retail centers?

- Steel products are used extensively in the construction of shopping malls and retail centers due to their strength, durability, and versatility. Steel beams and columns provide the structural framework, supporting the weight of the building and ensuring its stability. Steel is also used for roofing, cladding, and façade systems, providing a sleek and modern aesthetic. Additionally, steel is used for escalators, elevators, and staircases, as well as for mezzanines and catwalks within the mall. Its ability to be fabricated into different shapes and sizes allows for flexible and efficient construction, making steel an integral component in the development of shopping malls and retail centers.

- Q: How are steel plates used in the fabrication of storage tanks?

- Steel plates are used in the fabrication of storage tanks to provide structural support and maintain the integrity of the tank. These plates are welded together to form the tank's shell and are strong enough to withstand the pressure and weight of the stored materials. Additionally, steel plates can be coated or lined to prevent corrosion and ensure the longevity of the tank.

- Q: What are the applications of steel in the petrochemical industry?

- Steel has numerous applications in the petrochemical industry due to its exceptional strength, durability, and resistance to extreme temperatures and corrosive environments. It is extensively used in the construction of storage tanks, pipelines, and equipment for the processing and transportation of petrochemicals. Additionally, steel is utilized in the fabrication of heat exchangers, reactors, and furnaces, where it plays a crucial role in maintaining operational efficiency and safety.

- Q: How do steel products contribute to the construction of zoos and wildlife sanctuaries?

- Steel products contribute to the construction of zoos and wildlife sanctuaries in various ways. Firstly, steel is a durable and strong material that is used to create the framework and support structures of zoo exhibits and enclosures, ensuring the safety and security of the animals. Additionally, steel is used in the construction of visitor facilities like walkways, observation decks, and viewing platforms, allowing visitors to safely observe and interact with the animals. Steel products also play a crucial role in the creation of gates, fences, and barriers, helping to keep the animals secure and prevent any unwanted interactions. Overall, steel products provide the necessary strength, stability, and versatility required for the construction of zoos and wildlife sanctuaries.

- Q: What are the different types of steel angles and channels available?

- There are several different types of steel angles and channels available, including equal angles, unequal angles, C channels, and U channels. Equal angles have equal sides and are commonly used for structural applications, while unequal angles have different side lengths and are often used for bracing or support in construction projects. C channels have a C-shaped cross-section and are typically used for structural support, while U channels have a U-shaped cross-section and are often used for edging or framing.

Send your message to us

Hot Rolled Steel Billet China Supplier/Made In China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords