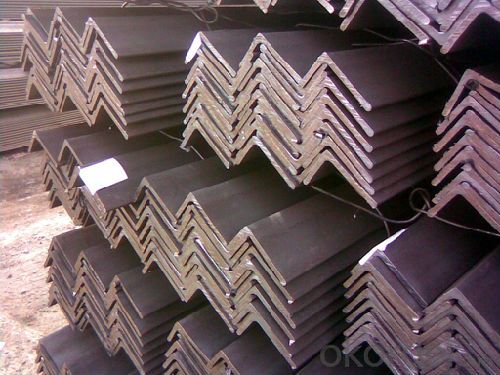

Hot rolled steel angle steel angle for constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot rolled steel angle steel angle for constrution at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel angle steel angle for constrution are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications

1) . Easy to install, fire proof, good insulation

2). Certification: ISO9001:2000, SGS Standard.

Steel Structure Warehouse:

1.The steel structure of the connection method: welding connection

2.Steel structure design common norms are as follows: "Steel Design Code" (GB50017-2003) Cold-formed steel structure technical specifications" (GB50018-2002) "Construction Quality Acceptance of Steel" (GB50205-2001) "Technical Specification for welded steel structure" (JGJ81-2002, J218-2002) "Technical Specification for Steel Structures of Tall Buildings" (JGJ99-98)

3.The characteristics of steel Light weight steel structure Higher reliability of steel work Steel anti-vibration (earthquake), impact and good Steel structure for a higher degree of industrialization Steel can be assembled quickly and accurately Large steel interior space Likely to cause sealing structure Steel corrosive Poor fire-resistant steel Recyclable steel shorter duration

4.Commonly used steel grades and performance of steel Carbon

structural steel: Q195, Q215, Q235, Q255, Q275, etc.

High-strength low-alloy structural steel Quality carbon structural steel and alloy structural steel Special purpose steel Product Feature Carport, House, Office, Shop, Toilet, Villa, Warehouse, Workshop, Plant Other Information

Products have been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North America, the Middle East, Africa, Asia and other countries and regions, the widespread use

Welcome to our factory, we assure that our products will satisfy your needs with designs, competitive performance price ratio and best services.

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase?

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the design considerations for steel mining plants?

- Some key design considerations for steel mining plants include ensuring structural integrity and stability to withstand heavy loads and equipment, incorporating efficient transportation systems for moving materials and products within the plant, implementing effective ventilation and dust control measures for worker safety and environmental protection, and considering the potential for expansion or modification in the future. Additionally, factors such as accessibility, site topography, and local regulations should also be taken into account during the design process.

- Q: How does the design of steel structures differ for industrial applications?

- The design of steel structures for industrial applications differs in several key aspects. Firstly, industrial structures often require higher load-bearing capacities compared to other types of buildings due to the heavy machinery, equipment, and materials they house. This necessitates the use of thicker steel sections and stronger connections to ensure structural integrity and safety. Additionally, industrial structures are typically designed with large clear spans to accommodate expansive manufacturing or storage areas without the need for internal columns, allowing for maximum flexibility in layout and operations. This requires careful consideration of the structural system, such as the selection of trusses or beams, to efficiently distribute loads and minimize deflection. Moreover, industrial structures often incorporate specific design features to address unique requirements. For example, they may include overhead cranes, mezzanines, or special ventilation systems, which demand additional considerations in terms of load distribution, access points, and integration with the overall structural design. Lastly, industrial structures also need to adhere to specific building codes and regulations related to fire protection, seismic resistance, and environmental considerations. This may involve the incorporation of fireproofing materials, seismic bracing, or sustainable design features to ensure compliance and minimize potential risks. Overall, the design of steel structures for industrial applications involves a comprehensive understanding of the functional needs, load requirements, and regulatory constraints to create safe, efficient, and durable facilities that can withstand the demands of industrial operations.

- Q: Construction technology practice of steel structure in interior decoration

- Home improvement, steel structure interlayer construction methods: the main beam using different types of I-beam, general 12cm can. Or to channel steel transverse arrangement of 60--80cm span longitudinal rectangular steel pipe connection, the formation of 400 ~ 600mm Affirmative or rectangular mesh structure to do anti rust treatment.

- Q: What are the common design considerations for steel structures in residential buildings?

- Some common design considerations for steel structures in residential buildings include the structural integrity and strength of the steel framework, the load-bearing capacity of the structure, fire resistance, corrosion protection, and the aesthetic appeal of the steel elements. The design also takes into account factors such as the building's location, local building codes and regulations, seismic activity, and environmental sustainability. Additionally, considerations for ease of construction, cost-effectiveness, and the ability to accommodate future modifications or expansions may also be taken into account.

- Q: What are the factors influencing the choice between steel and concrete structures?

- The factors influencing the choice between steel and concrete structures include cost, design flexibility, construction speed, durability, sustainability, and aesthetic preferences.

- Q: What are the factors to consider when designing steel structures for open spaces and stadiums?

- When designing steel structures for open spaces and stadiums, several key factors need to be considered. Firstly, the structural integrity and load-bearing capacity of the steel framework are crucial. This involves assessing the potential loads, such as the weight of the roof, seating, and equipment, as well as any potential dynamic loads caused by wind or seismic activity. Secondly, the architectural and aesthetic requirements of the open space or stadium should be taken into account. The design should align with the desired visual appeal, while also ensuring practical functionality and ease of maintenance. Additionally, the steel structure's durability and resistance to corrosion and weather conditions should be evaluated. This involves choosing suitable materials and protective coatings to ensure the longevity and safety of the structure. Moreover, considering the intended use of the open space or stadium is essential. Factors such as seating arrangements, sightlines, acoustics, and accessibility for spectators and players need to be integrated into the design. Lastly, project budget and timeline constraints must also be considered when designing steel structures for open spaces and stadiums. Balancing the desired design and functionality with the available resources is crucial for successful project execution.

- Q: How are steel structures designed for efficient use of natural ventilation and heating?

- Various techniques can be employed to maximize the efficient use of natural ventilation and heating in steel structures. Incorporating openings such as windows, vents, and louvers is a key consideration for natural ventilation. These openings allow for the free flow of air, promoting cross-ventilation and ensuring a constant supply of fresh air. To optimize natural heating, solar energy can be harnessed in the design of steel structures. Strategic placement of windows and skylights allows sunlight to penetrate the interior spaces. Additionally, thermal mass materials like concrete or stone can be integrated into the structure to absorb and store solar heat during the day, releasing it in the cooler evenings. Passive design strategies further enhance natural ventilation and heating in steel structures. Building orientation can be utilized to maximize exposure to prevailing winds, and natural landscape features like trees and vegetation can serve as windbreaks or provide shade during summer months. Insulated building envelopes, such as insulated metal panels, significantly improve energy efficiency by minimizing heat transfer through walls and roofs. This reduces the need for artificial heating or cooling. Smart control systems can be integrated into the design of steel structures to optimize natural ventilation and heating. These systems monitor indoor and outdoor conditions, automatically adjusting window openings, louvers, or blinds to allow for optimal airflow and heat exchange. In conclusion, the efficient use of natural ventilation and heating in steel structures is achieved through the integration of openings, passive design strategies, thermal mass materials, insulated building envelopes, and smart control systems. These considerations not only enhance comfort and indoor air quality but also contribute to energy savings and environmental sustainability.

- Q: How are steel structures used in the construction of religious buildings?

- Religious buildings often incorporate steel structures for their long-lasting, sturdy, and versatile properties. Steel serves as a robust foundation capable of supporting the weight of intricate architectural designs. In the construction of churches, temples, mosques, or synagogues, steel is frequently employed to establish the framework for roofs, walls, and other structural elements. By using steel, religious buildings can feature open and spacious interiors, allowing natural light to permeate the space and evoking a sense of grandeur. One of the primary advantages of utilizing steel structures in religious buildings lies in its ability to span lengthy distances without the necessity for intermediate support columns. This permits the creation of expansive areas, fostering a feeling of unity and openness that is often sought after in religious architecture. Moreover, steel structures can be effortlessly modified or expanded, facilitating adjustments to accommodate future growth or changes within the religious community. This adaptability enables religious buildings to meet the evolving needs of the congregation. Steel structures also possess outstanding resistance to fire, earthquakes, and other natural calamities, ensuring a safe and secure environment for worshipers. This attribute is particularly crucial in regions prone to seismic activity or extreme weather conditions. Furthermore, steel is an environmentally sustainable material that can be recycled, reducing the demand for fresh raw materials and minimizing the carbon footprint of the construction process. In conclusion, the utilization of steel structures in the construction of religious buildings allows for the creation of captivating architectural designs that are both functional and visually pleasing. It establishes a robust, long-lasting, and flexible framework that can cater to the needs of the religious community while establishing an atmosphere of sanctity.

- Q: What are the considerations for steel structure design in coastal areas?

- When designing steel structures in coastal areas, several considerations need to be taken into account. Firstly, the corrosive effects of saltwater and airborne salts are significant. Therefore, the selection of corrosion-resistant materials and protective coatings is crucial to ensure the longevity and durability of the structure. Secondly, the high wind loads and potential for hurricanes or cyclones in coastal areas require the steel structure to be designed to withstand these extreme weather conditions. This includes adequate bracing, anchoring, and connections to resist lateral forces. Thirdly, the proximity to the ocean means that the structure may be exposed to high levels of moisture and humidity. Proper ventilation and drainage systems should be incorporated to prevent the accumulation of moisture and subsequent corrosion. Additionally, the design of steel structures in coastal areas should consider potential wave impact and flooding. Ensuring the foundation is built above the flood level and incorporating design features to redirect or absorb wave energy can help mitigate any potential damage. Lastly, environmental factors such as marine life and saltwater spray should also be considered. Design elements that deter marine growth and protect against saltwater ingress, such as coatings and sacrificial anodes, may be necessary. Overall, the considerations for steel structure design in coastal areas revolve around corrosion resistance, wind load resistance, moisture control, wave impact and flooding protection, and protection against marine life and saltwater spray.

- Q: What are the advantages of using steel structures in bridge construction?

- There are several advantages of using steel structures in bridge construction. Firstly, steel is a very strong and durable material, allowing bridges to withstand heavy loads and harsh weather conditions. Secondly, steel structures are lightweight compared to other materials like concrete, which makes them easier and faster to construct. Thirdly, steel is highly flexible and can be shaped into various designs, allowing for creative and aesthetically pleasing bridge structures. Additionally, steel is a recyclable material, making it an environmentally friendly choice. Lastly, steel structures require minimal maintenance and have a long lifespan, resulting in cost savings in the long run.

Send your message to us

Hot rolled steel angle steel angle for constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches