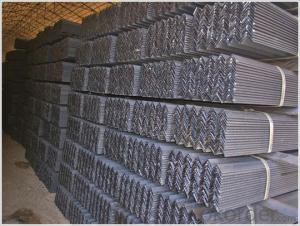

Hot Rolled Steel Angle Bar with High Quality 70*70mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 70*70*6 | 6.406 | 70*70*8 | 8.373 |

| 70*70*7 | 7.398 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used in telecommunications towers?

- Certainly, telecommunications towers can incorporate steel angles. Due to their robustness, longevity, and cost efficiency, steel angles are frequently employed in the construction of telecommunications towers. They are commonly utilized within the tower's framework to deliver stability and structural reinforcement. The exceptional tensile strength of steel angles enables them to withstand substantial loads, intense winds, and various environmental elements that telecommunication towers may confront. Moreover, the adaptability of steel angles permits customization and seamless installation, rendering them a favored option within the telecommunications sector.

- Q: Can steel angles be used in outdoor applications?

- Steel angles have a wide range of uses in outdoor settings. They are frequently employed in construction projects, serving as essential components in outdoor structures like fences, gates, and outdoor staircases. Moreover, they are extensively utilized in outdoor equipment and machinery, fulfilling purposes such as supporting brackets for solar panels or frames for outdoor signage. Thanks to their exceptional durability and resistance to corrosion, steel angles are capable of enduring outdoor elements such as rain, wind, and sunlight. Furthermore, these angles can be further fortified against rust and other types of corrosion through galvanization or the application of protective finishes. Overall, steel angles are a reliable and versatile option for outdoor applications due to their strength, durability, and resilience to various weather conditions.

- Q: What is the maximum shear force for a steel angle?

- The maximum shear force for a steel angle depends on various factors such as the size, shape, and material properties of the angle. To determine the specific maximum shear force, it is essential to consult the relevant design codes, standards, or specifications that provide guidelines for calculating the shear capacity of steel angles.

- Q: How do steel angles perform under dynamic loads?

- Steel angles generally perform well under dynamic loads due to their inherent strength and durability. The structural shape of steel angles, characterized by their L-shaped cross-section, provides excellent resistance to bending and torsional forces. This design allows them to efficiently distribute dynamic loads and resist deformation, making them suitable for various applications in construction, engineering, and manufacturing industries. However, the specific performance of steel angles under dynamic loads can vary depending on factors such as the grade and quality of the steel, the magnitude and frequency of the dynamic load, and the overall design and reinforcement of the structure.

- Q: What are the limitations of using steel angles in corrosive or saltwater environments?

- The use of steel angles in corrosive or saltwater environments is limited due to their susceptibility to corrosion. Steel is primarily composed of iron, which can react with oxygen and water to form iron oxide, commonly known as rust. In the presence of corrosive substances or saltwater, this corrosion process is accelerated. One limitation is the potential for accelerated corrosion in these environments. Corrosion weakens the structural integrity of the steel angles, which can compromise the overall stability and safety of any structure they are used in. This can be particularly concerning in applications where the steel angles are load-bearing or subjected to significant stress. Another limitation is the decrease in the lifespan of steel angles in corrosive or saltwater environments. The ongoing corrosion process can significantly reduce the lifespan of the steel angles, leading to more frequent maintenance or replacement requirements. This can result in higher costs and potential disruptions to operations or projects. Furthermore, the appearance of the steel angles can be negatively affected by corrosion in corrosive or saltwater environments. Rust stains can develop on the surface of the steel, which can be aesthetically unappealing, especially in applications where the steel angles are visible. To overcome these limitations, alternative materials can be considered for corrosive or saltwater environments. Stainless steel, for example, contains a high proportion of chromium, which provides it with enhanced corrosion resistance. Additionally, protective coatings or treatments, such as galvanizing or epoxy coatings, can be applied to steel angles to provide an additional barrier against corrosion. Overall, while steel angles are versatile and widely used in various applications, their use in corrosive or saltwater environments is limited due to their susceptibility to corrosion. It is crucial to carefully evaluate the specific environment and consider alternative materials or protective measures to ensure the longevity and integrity of any structure or project.

- Q: What are the different types of steel angles used in bridge construction?

- There are several types of steel angles commonly used in bridge construction. These angles play a crucial role in providing structural support and stability to the bridge. 1. Equal Leg Angles: Equal leg angles, also known as L-shaped angles, have two legs of equal length that form a 90-degree angle. These angles are used in bridge construction to provide support and reinforcement to the bridge components. 2. Unequal Leg Angles: Unequal leg angles, as the name suggests, have two legs of different lengths that form a 90-degree angle. These angles are commonly used in bridge construction to accommodate specific design requirements and support varying loads. 3. Bulb Angles: Bulb angles are special types of angles that have a bulb-shaped leg. These angles are used in bridge construction to provide additional strength and rigidity to the bridge structure, particularly in areas where high stress or heavy loads are anticipated. 4. Inverted Angles: Inverted angles are similar to equal leg angles, but the orientation is inverted, with the longer leg on the bottom. These angles are commonly used in bridge construction to provide additional support and stability, especially in situations where the bridge needs to withstand lateral forces. 5. Fillet Welded Angles: Fillet welded angles are angles that are joined together using fillet welds. These angles are used in bridge construction to create strong and durable connections between different bridge components, ensuring structural integrity and stability. Each type of steel angle has its unique properties and advantages, making them suitable for specific applications in bridge construction. The selection of the appropriate angle type depends on factors such as load requirements, span length, design specifications, and structural considerations. Professional engineers and designers carefully assess these factors to determine the best type of steel angle to be used in a specific bridge construction project.

- Q: Where does channel steel use more? Where does angle iron use more?

- Hot rolled stainless steel ordinary channel (GB707-88) main use: ordinary channel steel, mainly used for building structures, vehicle manufacturing and other industrial structures, often with the use of i-beam.

- Q: Are steel angles resistant to fire?

- Fire resistance is generally attributed to steel angles. Steel, being a non-combustible substance, does not burn or aid in the propagation of fire. However, it should be noted that while steel itself is fire-resistant, it can lose its strength when exposed to prolonged high temperatures. In the event of a fire, the temperature can rise rapidly and cause the steel to weaken, potentially compromising the structural integrity of a building or component. To improve fire resistance, fire-resistant coatings such as intumescent paint or fireproofing materials can be applied to steel angles. These coatings offer additional insulation, delaying the steel's exposure to high temperatures and preventing failure. Ultimately, the fire resistance of steel angles depends on several factors, including the duration and intensity of the fire, as well as the measures taken to enhance their fire performance. To ensure the appropriate level of fire resistance for steel angles in a specific application, it is crucial to consult with fire protection experts and adhere to building codes and regulations.

- Q: What are the different load-carrying capacities for steel angles?

- The load-carrying capacities for steel angles can vary depending on several factors such as the size and shape of the angle, the type of steel used, and the specific application or use case. Generally, load-carrying capacities for steel angles are determined by considering the maximum allowable stress or load that the angle can withstand without experiencing permanent deformation or failure. This is often expressed in terms of the maximum axial or bending load that an angle can support. To determine the load-carrying capacity of a specific steel angle, engineers and structural designers refer to industry standards and guidelines, such as the American Institute of Steel Construction (AISC) Manual of Steel Construction. These standards provide tables and formulas that take into account various factors such as the angle's dimensions, thickness, and moment of inertia to calculate its load-carrying capacity. It is important to note that load-carrying capacities for steel angles are typically specified for specific loading conditions and safety factors. These factors include the type of load (e.g., axial or bending), the direction and magnitude of the applied load, and the safety factor required to ensure the structural integrity and durability of the angle. Therefore, it is essential to consult the relevant codes, standards, and engineering resources to determine the specific load-carrying capacity of a particular steel angle for a given application. Professional structural engineers and designers are best equipped to assess and determine the load-carrying capacities of steel angles based on their expertise and familiarity with the applicable design codes and standards.

- Q: What are the safety precautions when working with steel angles?

- To minimize the risk of accidents and injuries when working with steel angles, it is crucial to follow specific safety measures. Here are some essential considerations: 1. Personal Protective Equipment (PPE) is essential. Make sure to wear safety glasses, gloves, steel-toed boots, and a hard hat to protect yourself from potential hazards like flying debris, sharp edges, and falling objects. 2. Proper handling is key. Utilize mechanical aids such as cranes or forklifts to lift and move heavy steel angles. Avoid manual lifting if the weight exceeds your capacity. Ensure secure stacking of angles and avoid overloading shelves or racks. 3. Organize and keep the work area clean to prevent accidents. Remove any obstructions or clutter that may hinder movement. Clearly mark areas where steel angles are stored or being worked on to prevent unauthorized access. 4. Regularly inspect and maintain tools and equipment used to work with steel angles. Repair or replace any defects promptly and avoid using damaged or faulty equipment. 5. When cutting or grinding steel angles, wear appropriate eye and face protection to shield against sparks, dust, and debris. Use tools specifically designed for cutting and grinding steel. Ensure proper ventilation in enclosed spaces to minimize the risk of inhaling toxic fumes. 6. Store steel angles in a designated area where they are secure and not at risk of falling or causing accidents. Use racks or shelves suitable for supporting the weight and size of the angles. Securely stack and strap them to prevent toppling over. 7. Implement proper fire safety measures. Steel angles can generate sparks when cut or welded. Have fire extinguishers and fire-resistant materials nearby. Keep flammable substances away from the work area. 8. Provide adequate training to all workers handling steel angles. Ensure they understand safety precautions, procedures, and emergency protocols. Encourage open communication and reporting of safety concerns or incidents. By following these safety precautions, you can create a safer working environment and minimize the risk of accidents when handling steel angles. Always prioritize your safety and the safety of others in your work with steel angles.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 70*70mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords