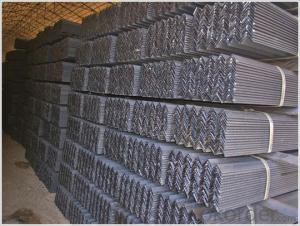

Hot Rolled Steel Angle Bar with High Quality 60*60mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 60*60*4 | 3.643 | 63*63*5 | 4.822 |

| 60*60*5 | 4.514 | 63*63*6 | 5.721 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What are the different fabrication techniques used for steel angles?

- There are several different fabrication techniques used for steel angles, depending on the specific requirements and desired outcome. Some of the commonly used techniques include: 1. Hot rolling: This is the most common fabrication technique for steel angles. In this process, the steel is heated above its recrystallization temperature and passed through a series of rollers to shape it into the desired angle profile. Hot rolling helps to improve the mechanical properties of the steel and provides a smooth surface finish. 2. Cold rolling: This technique is similar to hot rolling, but the steel is processed at room temperature. Cold rolling is often used to produce steel angles with tighter dimensional tolerances and improved surface finish. It also enhances the mechanical properties of the steel. 3. Laser cutting: Laser cutting is a precise and efficient fabrication technique used to cut steel angles into the desired shape and size. A high-powered laser beam is directed onto the steel, melting or vaporizing the material along the cutting path. Laser cutting offers excellent accuracy, speed, and versatility. 4. Welding: Welding is commonly used to join steel angles together or attach them to other structural components. Different welding techniques, such as arc welding, gas metal arc welding (MIG), or tungsten inert gas (TIG) welding, can be employed depending on the specific application and the desired strength of the joint. 5. Bending: Bending is another technique used to fabricate steel angles. It involves applying force to the steel to bend it into the desired angle shape. Bending can be done using various methods, including press brakes, rollers, or hydraulic machines. This technique is often used when precise angle measurements and specific radius requirements are needed. 6. CNC machining: Computer Numerical Control (CNC) machining is a highly precise and automated fabrication technique used to produce steel angles with complex shapes and intricate details. CNC machines use computer-controlled tools to remove material from the steel, creating the desired angle profile. Each fabrication technique has its own advantages and limitations, and the choice of technique depends on factors such as the required angle dimensions, tolerances, surface finish, and the intended application of the steel angles.

- Q: How does the weight of a steel angle affect its load-bearing capacity?

- The load-bearing capacity of a steel angle is directly impacted by its weight. Generally, a heavier steel angle possesses a greater load-bearing capacity compared to a lighter one. This is due to the weight of the angle contributing to its overall strength and stability. When a load is exerted on a steel angle, it generates both compressive and tensile forces within the material. The weight of the angle aids in evenly distributing these forces, minimizing the likelihood of deformation or failure. Moreover, a heavier steel angle typically signifies a higher density and a larger quantity of material utilized in its construction. Consequently, the angle can endure larger loads without experiencing significant deflection or structural damage. It is crucial to acknowledge that the load-bearing capacity of a steel angle is also influenced by additional factors such as its dimensions, material properties, and the type of connection employed. Nonetheless, the weight of the angle remains a vital consideration in determining its overall strength and ability to support loads.

- Q: What are the different types of corrosion protection coatings for steel angles?

- For steel angles, there exists a variety of corrosion protection coatings that serve different purposes in safeguarding against corrosion. 1. Paint Coatings: Paint coatings are frequently employed for corrosion protection of steel angles. Acting as a barrier, they shield the steel surface from corrosive elements present in the surroundings. These coatings are typically applied in multiple layers and can be tailored to meet specific needs, such as resistance to chemicals or UV radiation. 2. Galvanizing: Another extensively used method for corrosion protection in steel angles is galvanizing. This process entails the application of a zinc layer to the steel surface through hot-dip galvanizing. By acting as a sacrificial anode, this coating provides excellent corrosion protection, sacrificing itself before the steel. Galvanized steel angles are commonly utilized in outdoor settings where exposure to moisture and harsh weather conditions is expected. 3. Powder Coatings: Powder coatings, which are applied as a dry powder and cured with heat, offer a durable and corrosion-resistant finish for steel angles. These coatings can be customized in terms of color, texture, and thickness, ensuring both aesthetic appeal and enhanced protection against corrosion. 4. Epoxy Coatings: Industrial applications often require the use of epoxy coatings when steel angles may be exposed to harsh chemicals or abrasive environments. These coatings form a robust and protective layer that resists corrosion, chemicals, solvents, and abrasion. They can be applied as a single layer or combined with other coatings for added protection. 5. Organic Coatings: In architectural applications where corrosion protection is necessary while maintaining an attractive appearance, organic coatings such as polyurethane or acrylic coatings are commonly used for steel angles. These coatings offer good resistance to weathering, UV radiation, and corrosion, ensuring the longevity of the steel angles. When selecting a corrosion protection coating for steel angles, it is crucial to consider the specific application, environmental conditions, and budget constraints. Seeking advice from corrosion specialists or coating suppliers can help determine the most suitable coating for the intended use.

- Q: Can steel angles be used for retaining walls?

- Yes, steel angles can be used for retaining walls. Steel angles are commonly used in construction for various purposes, including supporting structures and creating retaining walls. They provide strength and stability to the wall, making them suitable for retaining soil or other materials. Steel angles can be used as a primary structural element or in combination with other materials, such as concrete or timber, to form a robust and durable retaining wall. The specific design and engineering considerations would depend on factors such as the height and load requirements of the wall, as well as the soil conditions and local building codes. However, with proper design and installation, steel angles can be an effective choice for retaining walls.

- Q: What are the common applications of steel angles in the automotive industry?

- Steel angles are commonly used in the automotive industry for various applications due to their versatility and strength. One common application of steel angles in the automotive industry is in the construction of vehicle frames and chassis. Steel angles are often used to provide structural support and rigidity to the frame, ensuring the overall strength and stability of the vehicle. Another common application of steel angles is in the fabrication of brackets and mounting components. These angles are used to attach various components such as engine mounts, suspension components, and exhaust systems to the vehicle's chassis. Steel angles provide a secure and reliable connection, ensuring the proper functioning and longevity of these components. Steel angles are also utilized in the manufacturing of safety features in automobiles. For instance, they are used in the construction of roll cages, which provide protection to the occupants in case of a rollover or collision. Steel angles are preferred for roll cages due to their high strength and ability to absorb and distribute impact forces, thereby enhancing the safety of the vehicle. Additionally, steel angles find application in the design and production of various automotive accessories and components. They are commonly used as reinforcement in door panels, fenders, and bumpers, improving the overall structural integrity of these parts. Steel angles are also employed in the fabrication of trailer hitches, tow bars, and roof racks, providing a strong and secure attachment point for towing and carrying heavy loads. In summary, steel angles play a crucial role in the automotive industry by providing structural support, facilitating secure connections, enhancing safety, and improving the overall performance and durability of vehicles and their components.

- Q: How do you calculate the section modulus of a steel angle?

- To calculate the section modulus of a steel angle, you need to know the dimensions and properties of the angle. The section modulus is a measure of the strength of a structural member and is used to determine its resistance to bending. The formula to calculate the section modulus of a steel angle is: Section Modulus (Z) = (Width of the angle * Height of the angle^2) / 6 In this formula, the width of the angle refers to the distance between the two legs, while the height of the angle is the length of one leg. The section modulus is typically expressed in cubic inches or cubic centimeters. To calculate the section modulus, first measure the width and height of the angle. Then substitute these values into the formula to find the section modulus. This value will give you an indication of the strength and stiffness of the steel angle, which can be used in structural design and analysis.

- Q: What are the different methods of surface preparation for steel angles?

- Some of the different methods of surface preparation for steel angles include abrasive blasting, chemical cleaning, and mechanical cleaning. Abrasive blasting involves using a high-pressure stream of abrasive material to remove rust, scale, and other contaminants from the surface of the steel. Chemical cleaning involves using chemicals to dissolve and remove rust and other contaminants. Mechanical cleaning involves using tools such as wire brushes or sandpaper to physically scrape or scrub the surface of the steel to remove rust and other contaminants. These methods are important in preparing the steel surface for painting, coating, or other forms of protection against corrosion.

- Q: What are the safety considerations when working with steel angles?

- When working with steel angles, there are several important safety considerations to keep in mind. 1. Personal Protective Equipment (PPE): Always wear the appropriate PPE, including safety glasses, gloves, and steel-toed boots, to protect yourself from potential hazards such as flying debris, sharp edges, or heavy objects falling. 2. Lifting and handling: Steel angles can be heavy and cumbersome, so it is crucial to use proper lifting techniques and equipment to avoid strains or injuries. Use lifting aids such as cranes, hoists, or forklifts when necessary, and never attempt to lift or carry steel angles alone if they exceed a safe weight limit. 3. Sharp edges and burrs: Steel angles often have sharp edges and burrs that can cause cuts or abrasions. Use caution when handling them and consider deburring or filing down any sharp edges to reduce the risk of injuries. 4. Secure and stable work area: Ensure that the work area is clean, organized, and free from any tripping hazards. Steel angles should be stored securely to prevent them from falling or rolling onto workers or equipment. 5. Welding and cutting: If welding or cutting steel angles, be aware of the potential hazards associated with these processes. Use adequate ventilation or respirators to protect against fumes and ensure that the work area is clear of flammable materials. Follow proper safety protocols and use appropriate welding or cutting equipment to minimize the risk of fire, burns, or electric shocks. 6. Structural stability: When steel angles are used as part of a larger structure, it is crucial to ensure that the design and construction adhere to industry standards and codes. This includes properly securing the angles, verifying load capacities, and conducting regular inspections to identify any signs of structural weaknesses or defects. 7. Training and supervision: Workers should receive proper training on the safe handling, storage, and use of steel angles. Supervisors should actively monitor the work area and provide guidance to ensure that safety protocols are followed at all times. By following these safety considerations, individuals can reduce the risk of accidents and injuries when working with steel angles.

- Q: Are steel angles available in different colors?

- Steel angles typically come in a standard metallic gray color, but it's possible to alter their color or appearance by applying different finishes or coatings. Options like powder coating, paint, or galvanization can offer a variety of colors to choose from. However, it's worth mentioning that the range of available colors may vary depending on the manufacturer or supplier.

- Q: Can steel angles be used as supports for mechanical or electrical equipment?

- Indeed, mechanical or electrical equipment can be supported by steel angles. Due to their versatility and strength, steel angles are apt for a diverse array of uses. They offer stability, rigidity, and support, effectively securing mechanical or electrical equipment. The L-shaped configuration of steel angles facilitates effortless attachment and installation, rendering them convenient for a multitude of mounting necessities. Moreover, steel angles can be readily tailored and fabricated to fulfill precise specifications, guaranteeing a dependable and trustworthy support system for the equipment.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 60*60mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords