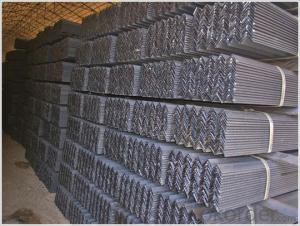

Hot Rolled Steel Angle Bar with High Quality 80*80mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 80*80*6 | 7.376 | 80*80*8 | 9.658 |

| 80*80*7 | 8.525 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: How do steel angles perform in high-humidity environments?

- Due to their corrosion-resistant properties, steel angles exhibit excellent performance in high-humidity environments. While the air's moisture content often causes metals to rust and corrode, steel angles are specifically engineered to withstand these conditions. Typically manufactured using stainless steel or galvanized steel, both materials possess a protective layer that effectively hinders rust formation. Consequently, steel angles are exceptionally well-suited for utilization in regions with high humidity, such as coastal areas or industrial settings where moisture is abundant. Moreover, their durability and extended lifespan further contribute to their exceptional performance in high-humidity environments.

- Q: Are steel angles suitable for playground equipment?

- Indeed, playground equipment can be made from steel angles as they possess the necessary attributes of strength, durability, and versatility. These angles are frequently employed in the construction of playground equipment due to their ability to endure rigorous usage and withstand the weight of numerous children. By conveniently welding or bolting steel angles together, a solid framework can be established, enabling the creation of an array of playground structures like climbing frames, swings, and slides. Moreover, the galvanization of steel angles serves to shield against corrosion, thereby prolonging the lifespan of the playground equipment and guaranteeing the safety of children during playtime.

- Q: How do you determine the required angle size for a specific application?

- To determine the required angle size for a specific application, you need to consider factors such as the purpose of the application, the type of material being used, and the desired outcome. It is important to analyze the application's requirements, consult relevant guidelines or standards, and consider any potential safety or functional considerations. Additionally, conducting tests or simulations can help determine the appropriate angle size for optimal performance and efficiency in the given application.

- Q: Can steel angles be used for overhead support in industrial settings?

- Yes, steel angles can be used for overhead support in industrial settings. Steel angles are versatile and strong structural components that can provide the necessary support for various overhead applications. They are commonly used in the construction industry for their ability to bear heavy loads and withstand high levels of stress. Steel angles are often employed in the construction of frameworks, trusses, and supports for overhead conveyors, cranes, piping systems, and other industrial equipment. Their durability, resistance to corrosion, and ability to be easily welded or bolted make them an ideal choice for providing overhead support in industrial settings.

- Q: Angle iron specifications 125 * 80 * 101 m multiple

- Angle steel is a kind of carbon structural steel for construction. It is a simple section steel, mainly used in the frame of metal component and workshop. In use, better weldability, plastic deformation and mechanical strength are required. The raw steel billet for producing angle steel is low carbon square billet, and the finished product angle iron is made by hot rolling, normalizing or hot rolling.

- Q: Can steel angles be used for framing or supporting mezzanines or elevated platforms?

- Yes, steel angles can be used for framing or supporting mezzanines or elevated platforms. Steel angles provide structural support, stability, and can be easily connected to other steel components. They are commonly used in construction projects for their strength and versatility.

- Q: How do steel angles contribute to the durability of a structure?

- Steel angles contribute to the durability of a structure by providing additional strength and stability. They are used to reinforce connections and support load-bearing components, ensuring structural integrity and withstanding various forces such as gravity, wind, and seismic loads. The angle shape of the steel allows for efficient distribution of stress and prevents bending or deformation, enhancing the overall durability and longevity of the structure.

- Q: I would like to ask you, angle iron, what does it usually use ah?

- Mainly used for making steel frame structure, such as high-voltage transmission tower, steel structure bridge on both sides of the frame, the construction site of the tower crane arm, workshop columns and columns and beams, small holiday places such as roadside stands, the window in the other pot under the air conditioning solar rack etc..

- Q: Can steel angles be cold-formed or bent to specific shapes?

- Indeed, it is possible to cold-form or bend steel angles to attain particular shapes. Cold forming refers to the act of reshaping metal without the application of heat, usually accomplished through techniques such as bending, rolling, or pressing. Steel angles, which consist of L-shaped steel components, can undergo cold forming to achieve diverse shapes and angles in accordance with project specifications. This procedure entails exerting force and pressure on the steel angle, resulting in its deformation and acquisition of the desired form. By employing cold forming techniques on steel angles, one can achieve design flexibility and customization while preserving the strength and durability of the steel material.

- Q: What are the different types of steel angles used in door and window frames?

- Door and window frames commonly utilize different types of steel angles, each with its own advantages and uses. Firstly, the L-shaped angle is the most frequently employed steel angle in these frames. It possesses a 90-degree angle and is primarily used to provide structural support and reinforcement. L-shaped angles are versatile, allowing for easy welding or bolting into place, making them suitable for various frame designs. Secondly, T-shaped angles, as the name suggests, resemble the letter "T" in their cross-section. They are often incorporated to enhance the strength and stability of door and window frames. T-shaped angles are commonly utilized in heavy-duty applications where increased load-bearing capacity is necessary. Equal angles, with two equal sides forming a 90-degree angle, are also commonly found in door and window frames. These angles are ideal for applications requiring equal support on both sides. Their usage ensures symmetry and balance, thereby maintaining frame stability and levelness. On the other hand, unequal angles possess sides of varying lengths. They are frequently utilized in door and window frames that require differing levels of support on each side. Their versatility allows them to compensate for differences in wall thickness or other structural considerations. Lastly, slotted angles are often preferred for door and window frames that require adjustable or modular designs. They incorporate a series of holes or slots along their length, facilitating easy attachment and customization. Slotted angles are commonly employed in DIY projects or applications that prioritize flexibility and adjustability. It is important to note that the selection of a steel angle for door and window frames depends on various factors such as the specific application, load-bearing requirements, and aesthetic considerations. Seeking consultation from a structural engineer or a professional in the field can aid in determining the most suitable type of steel angle for a particular project.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 80*80mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords