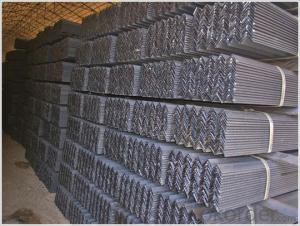

Hot Rolled Steel Angle Bar with High Quality 100*100mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 100*75*7 | 9.32 | 100*75*10 | 13.0 |

| 100*75*8 | 10.6 | 100*75*12 | 15.4 |

| 100*75*9 | 11.8 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used for support structures in stadiums or arenas?

- Yes, steel angles can be used for support structures in stadiums or arenas. Steel angles are commonly used in construction and engineering projects due to their strength, durability, and versatility. They are often utilized in structural applications where load-bearing support is required, making them suitable for supporting the weight of stadium or arena structures. Steel angles can be used as beams, columns, or trusses to provide the necessary support and stability for large structures. Their ability to withstand heavy loads and resist bending or warping makes them a popular choice for constructing stadium roofs, grandstands, and other support systems. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, allowing for efficient and cost-effective construction of stadium and arena support structures.

- Q: What are the common methods of surface finishing for steel angles?

- Steel angles can be surface finished in various ways to achieve specific aesthetic and functional properties. The following methods are commonly used: 1. Paint application: To protect against corrosion and enhance appearance, a protective coat of paint is applied to the steel angle. Different types of paint, like epoxy, acrylic, or powder coatings, are chosen based on specific needs. 2. Galvanization: This method involves immersing the steel angle in molten zinc to create a protective layer on its surface. Galvanization is particularly effective for steel angles exposed to harsh environments or outdoor use. 3. Powder coating: In this process, a dry powder is electrostatically sprayed onto the steel angle and then cured in an oven. The result is a durable finish that resists chipping, fading, and corrosion. Powder coating is preferred when a thicker, more robust finish is desired. 4. Anodizing: Although mainly used for aluminum, anodizing can also be applied to steel angles. It creates an oxide layer on the surface through an electrochemical process, providing increased corrosion resistance and the option to add color. 5. Shot blasting: This surface preparation technique involves bombarding the steel angle with small steel shots at high velocity. Shot blasting removes rust, mill scale, and other impurities, leaving the surface clean and prepared for further finishing processes. 6. Polishing: This technique mechanically smooths and shines the steel angle's surface, achieving a reflective, mirror-like finish or removing imperfections. These methods offer different advantages and are suitable for various applications. The choice of method depends on factors such as desired appearance, environmental conditions, and specific performance requirements.

- Q: Can steel angles be used in the construction of shopping malls?

- Yes, steel angles can be used in the construction of shopping malls. Steel angles are versatile structural components that can provide support and stability to various elements of a building, including shopping malls. They are commonly used in the construction industry for framing, bracing, and reinforcing structures. Steel angles can be used to support the walls, roof, and floors of shopping malls, ensuring the structural integrity of the building. Additionally, they can be used in the construction of staircases, escalators, and mezzanines within the shopping mall. The use of steel angles in shopping mall construction offers several advantages, including their durability, strength, and cost-effectiveness.

- Q: What is the maximum load capacity for a steel angle beam?

- The maximum load capacity for a steel angle beam depends on various factors such as the size and dimensions of the beam, the grade of steel used, and the specific application or intended use. Steel angle beams are commonly used in construction and structural applications for supporting loads, but the exact maximum load capacity can vary. It is important to consult engineering specifications, structural design codes, or consult with a structural engineer to determine the specific maximum load capacity for a steel angle beam in a particular scenario.

- Q: Are steel angles prone to rust or corrosion?

- Yes, steel angles are prone to rust or corrosion as they are typically made of carbon steel, which is susceptible to rusting when exposed to moisture and oxygen.

- Q: Can steel angles be used in outdoor or exposed applications?

- Yes, steel angles can be used in outdoor or exposed applications. Steel angles are commonly made from galvanized steel, which is coated with a protective layer of zinc. This zinc coating helps to prevent corrosion and rust, making them suitable for outdoor use. Additionally, steel angles are durable and strong, making them suitable for various applications such as construction, infrastructure, and outdoor furniture. However, it is essential to ensure proper maintenance and periodic inspection to identify any signs of corrosion or damage and take necessary actions to prevent potential issues.

- Q: Can steel angles be used in the construction of religious institutions?

- Yes, steel angles can be used in the construction of religious institutions. Steel angles are versatile and commonly used in construction due to their strength, durability, and ability to withstand heavy loads. They can be used to provide structural support and stability to the building, ensuring its longevity and safety. Whether it is for columns, beams, trusses, or framing, steel angles can be effectively utilized in the construction of religious institutions to meet the specific design and engineering requirements.

- Q: Can steel angles be used for fencing and gate construction?

- Yes, steel angles can be used for fencing and gate construction. Steel angles are commonly used in construction projects due to their strength and durability. They provide a strong framework for fencing and gate structures, offering support and stability. Steel angles can be easily welded or bolted together to form the desired shape and size for fencing and gate construction. Additionally, steel angles have a high resistance to corrosion, making them suitable for outdoor applications. Overall, steel angles are a versatile and reliable choice for fencing and gate construction.

- Q: What are the typical lifespan and durability of steel angles?

- The typical lifespan and durability of steel angles can vary depending on several factors such as the quality of the steel, environmental conditions, and maintenance. However, steel angles are known for their long lifespan and high durability. With proper care and maintenance, steel angles can last for several decades or even longer.

- Q: Can galvanized square tubes and angle iron be welded together?

- Yes, if the requirement is not high, it can be welded directly. If the requirement is high, the zinc coating on the galvanized square pipe can be polished off before welding, and then welded. However, two kinds of welding methods, welding well, must be carried out at the weld corrosion. Now there is a special coating for hot-dip galvanizing on the market. It is characterized by high zinc content and 96% zinc content. It can provide similar anticorrosive effect to hot-dip galvanizing for repairing parts.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 100*100mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords