Structure Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25m.t. m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

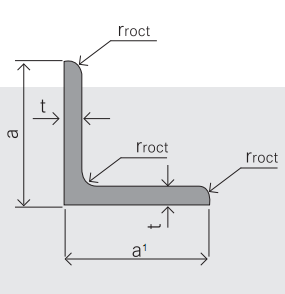

Specifications of Structure Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

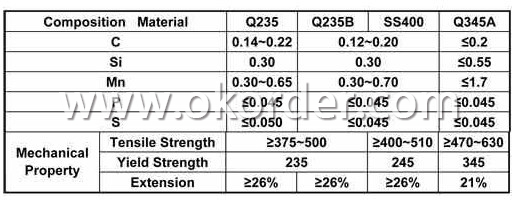

6. Material details:

Usage & Applications of Structure Angle Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Structure Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be used for supports in bridges?

- Yes, steel angles can be used for supports in bridges. Steel angles provide structural stability and strength, making them suitable for supporting heavy loads in bridge construction.

- Q: How do you determine the required thickness of a steel angle for a specific load?

- To determine the required thickness of a steel angle for a specific load, various factors need to be considered. These include the magnitude and direction of the load, the length and support conditions of the angle, and the desired safety factor. By analyzing these factors, engineers can utilize structural analysis techniques and calculations to determine the appropriate thickness of the steel angle that can withstand the given load without experiencing failure or excessive deflection.

- Q: Are steel angles suitable for high-temperature environments?

- Steel angles can be suitable for high-temperature environments depending on the specific type of steel used. Certain grades of stainless steel, such as 304 and 316, are known for their excellent heat resistance properties. These stainless steel angles can withstand high temperatures without significant loss of strength or corrosion resistance. They also exhibit good oxidation resistance, which is crucial in high-temperature environments where oxidation can occur. However, it is important to note that not all steel angles are suitable for high-temperature applications. Carbon steels, for example, are not recommended for prolonged exposure to high temperatures as they can undergo significant structural changes, such as softening or even melting, which can compromise their integrity and strength. When selecting steel angles for high-temperature environments, it is essential to consider the specific temperature range, duration of exposure, and any additional factors such as corrosive gases or chemicals present. Consulting with a material engineer or a steel supplier with expertise in high-temperature applications can help ensure the selection of the appropriate steel angle with the necessary heat resistance properties for the specific environment.

- Q: What are the different types of steel angles used in structural engineering?

- There are several types of steel angles commonly used in structural engineering, including equal angles, unequal angles, L-shaped angles, and T-shaped angles. Each type has its own specific applications and structural purposes.

- Q: Can steel angles be easily cut to size?

- Yes, steel angles can be easily cut to size using various tools such as saws or plasma cutters.

- Q: Can steel angles be used for conveyor supports?

- Yes, steel angles can be used for conveyor supports as they provide stability and strength due to their structural design.

- Q: How do you calculate the shear force on a loaded steel angle?

- In order to determine the shear force on a loaded steel angle, one must take into account the applied load, the angle's geometry, and the steel's material properties. The term "shear force" refers to the force that acts parallel to the angle's cross-sectional area. Firstly, it is crucial to ascertain the applied load that is acting upon the steel angle. This load can be either concentrated, distributed, or a combination of both. It is of utmost importance to accurately determine the load's magnitude and location. Subsequently, the steel angle's geometry should be considered. The angle consists of two legs, each possessing specific measurements of length, width, and thickness. Precise measurements of these dimensions are necessary. Once the load and angle dimensions are obtained, the shear force can be calculated by employing the following formula: Shear Force = Load / Cross-sectional Area To calculate the cross-sectional area, one must take into account the angle's shape. Typically, the cross-sectional area of a steel angle is calculated by adding together the areas of both legs and then subtracting the area of the corner radius. In the case of unequal legs, the cross-sectional area can be calculated by adding together the areas of the longer and shorter legs and subtracting the area of the corner radius. After determining the cross-sectional area, divide the applied load by this value to determine the shear force acting on the loaded steel angle. It is important to note that the aforementioned calculation assumes that the steel angle is solely subjected to pure shear. In practical scenarios, additional factors such as bending moments and torsion may need to be taken into consideration, which would necessitate more intricate calculations and analysis. Therefore, it is advisable to consult relevant design codes, principles of structural engineering, or seek the guidance of a professional engineer for accurate and reliable results.

- Q: How do you prevent rust on steel angles?

- One way to prevent rust on steel angles is by applying a protective coating or paint that acts as a barrier against moisture and oxygen. Additionally, keeping the steel angles dry and storing them in a controlled environment with low humidity can help prevent rust formation. Regular inspections and maintenance, such as cleaning and removing any dirt or corrosion, can also help in preventing rust on steel angles.

- Q: Can steel angles be used as supports for mechanical or HVAC ducts?

- Yes, steel angles can be used as supports for mechanical or HVAC ducts. Steel angles are commonly used in construction and engineering as they provide structural support and stability. They are strong and durable, capable of withstanding heavy loads and maintaining their shape over time. When properly installed, steel angles can effectively support the weight of mechanical or HVAC ducts, ensuring that they stay in place and do not sag or collapse. Additionally, steel angles can be easily customized and adjusted to fit specific duct sizes and configurations. Overall, steel angles are a reliable and cost-effective solution for supporting mechanical or HVAC ducts.

- Q: What is the typical length of a steel angle?

- Steel angles can have varying lengths depending on their purpose and application. Generally, a steel angle is commonly found at a length of 20 feet or 6 meters. This standard length facilitates convenient handling, transportation, and installation in diverse construction and fabrication projects. Nevertheless, it is important to acknowledge that steel angles can be tailored or trimmed to shorter lengths in order to meet specific requirements or accommodate specific designs.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; middle east; South Korea; Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30%-45% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

Structure Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25m.t. m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords