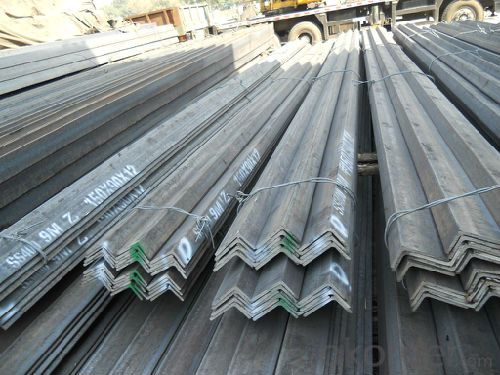

Low Carbon Prime Steel Equal Angle Bars in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Low Carbon Prime Steel Equal Angle Bars in High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Low Carbon Prime Steel Equal Angle Bars in High Quality are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries

Product Advantages:

OKorder's Low Carbon Prime Steel Equal Angle Bars in High Quality are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| EQUAL ANGLE STEEL | |||||

| size(mm) | a(mm) | a1(mm) | thickness(mm) | kg/m | length |

| 50*50*4 | 50 | 50 | 4 | 3.059 | 6m,9m,12m |

| 50*50*5 | 50 | 50 | 5 | 3.77 | 6m,9m,12m |

| 50*50*6 | 50 | 50 | 6 | 4.465 | 6m,9m,12m |

| 63*63*5 | 63 | 63 | 5 | 4.822 | 6m,9m,12m |

| 63*63*6 | 63 | 63 | 6 | 5.721 | 6m,9m,12m |

| 65*65*5 | 65 | 65 | 5 | 5 | 6m,9m,12m |

| 65*65*6 | 65 | 65 | 6 | 5.91 | 6m,9m,12m |

| 65*65*8 | 65 | 65 | 8 | 7.66 | 6m,9m,12m |

| 75*75*5 | 75 | 75 | 5 | 5.818 | 6m,9m,12m |

| 75*75*6 | 75 | 75 | 6 | 6.905 | 6m,9m,12m |

| 75*75*8 | 75 | 75 | 8 | 9.03 | 6m,9m,12m |

| 75*75*9 | 75 | 75 | 9 | 9.96 | 6m,9m,12m |

| 75*75*10 | 75 | 75 | 10 | 11.089 | 6m,9m,12m |

| 80*80*6 | 80 | 80 | 6 | 7.375 | 6m,9m,12m |

| 80*80*7 | 80 | 80 | 7 | 8.525 | 6m,9m,12m |

| 80*80*8 | 80 | 80 | 8 | 9.658 | 6m,9m,12m |

| 80*80*10 | 80 | 80 | 10 | 11.874 | 6m,9m,12m |

| 90*90*6 | 90 | 90 | 6 | 8.35 | 6m,9m,12m |

| 90*90*7 | 90 | 90 | 7 | 9.656 | 6m,9m,12m |

| 90*90*8 | 90 | 90 | 8 | 10.946 | 6m,9m,12m |

| 90*90*10 | 90 | 90 | 10 | 13.476 | 6m,9m,12m |

| 100*100*6 | 100 | 100 | 6 | 9.366 | 6m,9m,12m |

| 100*100*7 | 100 | 100 | 7 | 10.83 | 6m,9m,12m |

| 100*100*8 | 100 | 100 | 8 | 12.276 | 6m,9m,12m |

| 100*100*9 | 100 | 100 | 9 | 13.49 | 6m,9m,12m |

| 100*100*10 | 100 | 100 | 10 | 15.12 | 6m,9m,12m |

| 100*100*12 | 100 | 100 | 12 | 17.898 | 6m,9m,12m |

| 120*120*8 | 120 | 120 | 8 | 14.88 | 6m,9m,12m |

| 120*120*10 | 120 | 120 | 10 | 18.37 | 6m,9m,12m |

| 120*120*12 | 120 | 120 | 12 | 21.66 | 6m,9m,12m |

| 125*125*8 | 125 | 125 | 8 | 15.504 | 6m,9m,12m |

| 125*125*10 | 125 | 125 | 10 | 19.133 | 6m,9m,12m |

| 125*125*12 | 125 | 125 | 12 | 22.696 | 6m,9m,12m |

| 130*130*10 | 130 | 130 | 10 | 19.8 | 6m,9m,12m |

| 130*130*12 | 130 | 130 | 12 | 23.6 | 6m,9m,12m |

| 130*130*13 | 130 | 130 | 13 | 25.4 | 6m,9m,12m |

| 130*130*14 | 130 | 130 | 14 | 27.2 | 6m,9m,12m |

| 150*150*10 | 150 | 150 | 10 | 23 | 6m,9m,12m |

| 150*150*12 | 150 | 150 | 12 | 27.3 | 6m,9m,12m |

| 150*150*14 | 150 | 150 | 14 | 31.6 | 6m,9m,12m |

| 150*150*15 | 150 | 150 | 15 | 33.8 | 6m,9m,12m |

| 140*140*10 | 140 | 140 | 10 | 21.49 | 6m,9m,12m |

| 140*140*12 | 140 | 140 | 12 | 25.52 | 6m,9m,12m |

| 140*140*14 | 140 | 140 | 14 | 29.49 | 6m,9m,12m |

| 160*160*10 | 160 | 160 | 10 | 24.73 | 6m,9m,12m |

| 160*160*12 | 160 | 160 | 12 | 29.39 | 6m,9m,12m |

| 160*160*14 | 160 | 160 | 14 | 33.99 | 6m,9m,12m |

| 180*180*12 | 180 | 180 | 12 | 33.16 | 6m,9m,12m |

| 180*180*14 | 180 | 180 | 14 | 39.39 | 6m,9m,12m |

| 180*180*16 | 180 | 180 | 16 | 43.45 | 6m,9m,12m |

| 180*180*18 | 180 | 180 | 18 | 48.63 | 6m,9m,12m |

| 200*200*14 | 200 | 200 | 14 | 42.89 | 6m,9m,12m |

| 200*200*16 | 200 | 200 | 16 | 48.68 | 6m,9m,12m |

| 200*200*18 | 200 | 200 | 18 | 54.4 | 6m,9m,12m |

| 200*200*20 | 200 | 200 | 20 | 60.06 | 6m,9m,12m |

| 200*200*24 | 200 | 200 | 24 | 71.17 | 6m,9m,12m |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How many tons of steel products could be loaded in containers?

A3: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Are steel angles load-rated?

- Yes, steel angles are load-rated. The load rating of a steel angle depends on its dimensions, thickness, and material grade. The load rating is determined through engineering calculations and testing to ensure it can safely support specific loads and applications.

- Q: How does the price of steel angles vary based on size and grade?

- The price of steel angles varies based on size and grade, with larger sizes and higher grades typically commanding higher prices.

- Q: Can steel angles be used in the construction of sports stadiums?

- Yes, steel angles can be used in the construction of sports stadiums. Steel angles are versatile structural elements that can be used to support heavy loads and provide stability in large structures like sports stadiums. They are commonly used in the construction industry for various applications, including framing, support columns, and bracing systems. Steel angles offer excellent strength and durability, making them suitable for withstanding the dynamic forces and heavy loads experienced in sports stadiums. Additionally, steel angles can be easily fabricated and customized to fit the specific design and structural requirements of the stadium, offering flexibility in construction. Overall, steel angles are an ideal choice for the construction of sports stadiums due to their strength, versatility, and ability to withstand the unique demands of such large-scale structures.

- Q: How do steel angles perform in extreme temperatures?

- Steel angles are renowned for their exceptional performance in extreme temperatures. With their high melting point, they possess the ability to endure both exceedingly high and low temperatures without compromising their structural integrity. When faced with intense heat, steel angles display a remarkable resistance to thermal expansion, thereby preserving their form and strength. Similarly, even in extremely cold conditions, steel angles remain resilient and impervious to brittleness or weakness, ensuring their longevity and dependability. Consequently, steel angles are highly suitable for use in industries such as construction, automotive, and aerospace, where they are frequently subjected to a wide range of temperature variations. Furthermore, steel angles exhibit exceptional fire resistance, further augmenting their effectiveness in extreme temperature scenarios. All in all, when it comes to applications necessitating stability and strength in extreme temperatures, steel angles are the preferred choice.

- Q: How do steel angles perform in terms of water resistance or waterproofing?

- Steel angles typically do not have inherent water resistance or waterproofing properties. Since steel is a metal, it is susceptible to corrosion and rust when exposed to water or moisture for extended periods of time. However, the water resistance or waterproofing of steel angles can be improved through various measures. One common method is to apply a protective coating, such as galvanizing or painting, to the steel angles. Galvanizing involves coating the steel with a layer of zinc, which acts as a barrier against water and prevents corrosion. Painting, on the other hand, creates a protective layer that helps to seal out moisture and prevent direct contact between the steel and water. Additionally, proper design and installation techniques can also enhance the water resistance of steel angles. For example, ensuring proper drainage and avoiding water accumulation on or around the steel angles can prevent long-term exposure to moisture, reducing the risk of corrosion. It is important to note that even with these measures, steel angles may still be susceptible to water damage if the protective coatings become compromised or if there is constant exposure to harsh environmental conditions. Regular inspection, maintenance, and prompt repair or recoating of the steel angles are essential to ensure long-lasting water resistance.

- Q: How are steel angles protected against fire damage?

- Fire-resistant coatings and fireproofing materials are commonly used to protect steel angles from fire damage. These measures aim to prevent or delay the steel from reaching its critical temperature, which can compromise its structural integrity. One popular method of safeguarding steel angles involves applying intumescent coatings. These coatings expand when exposed to high temperatures, creating a protective char layer that insulates the steel and slows down heat transfer. This process effectively hinders the steel from rapidly increasing in temperature, thus enhancing its fire resistance capabilities. Another approach is to utilize fireproofing materials, such as concrete or gypsum-based sprays or boards. These materials act as a barrier between the steel angles and the fire, providing insulation and preventing the heat from reaching the steel. Fireproofing materials are commonly employed in buildings with higher fire resistance requirements, such as tall buildings or industrial facilities. In certain cases, steel angles can be enclosed within fire-rated enclosures for added protection. This entails enclosing the steel angles within fire-rated walls, floors, or ceilings made of materials with exceptional fire resistance properties. These enclosures effectively isolate the steel angles from potential fire sources, adding an extra layer of defense. It is important to acknowledge that the specific fire protection measures for steel angles can vary based on building codes, fire safety regulations, and the intended use of the structure. Consulting with fire protection engineers and adhering to the appropriate guidelines will ensure that the steel angles are adequately shielded against fire damage.

- Q: How do steel angles perform in terms of electromagnetic shielding?

- Steel angles are known to be effective in terms of electromagnetic shielding. This is primarily due to their high electrical conductivity and magnetic permeability. These properties allow steel angles to effectively redirect or absorb electromagnetic waves, thereby reducing their impact on nearby electronic devices or sensitive equipment. The shape and geometry of steel angles also contribute to their shielding capabilities, as they can be strategically positioned to create barriers or enclosures that block or divert electromagnetic fields. Additionally, the thickness or gauge of the steel angle can further enhance its shielding performance. Overall, steel angles are widely used in various applications where electromagnetic interference needs to be minimized or controlled, such as in construction, telecommunications, electronics, and automotive industries.

- Q: What is the typical hardness of steel angles?

- The typical hardness of steel angles can vary depending on the specific grade and manufacturing process. However, most commonly used steel angles have a hardness ranging between 120 and 280 on the Brinell hardness scale. It is important to note that the hardness of steel angles can be further influenced by factors such as heat treatment, alloy composition, and surface finishing. Therefore, it is recommended to refer to the specifications provided by the manufacturer or consult relevant industry standards to determine the precise hardness of a particular steel angle.

- Q: Can steel angles be used for manufacturing door frames?

- Yes, steel angles can be used for manufacturing door frames. Steel angles provide stability, strength, and durability, making them suitable for supporting and reinforcing door frames.

- Q: Can steel angles be used in architectural sculptures and installations?

- Yes, steel angles can be used in architectural sculptures and installations. Steel angles are versatile and commonly used in construction due to their strength and durability. They can be easily welded, bolted, or attached using other methods, making them ideal for creating intricate and complex structures. Steel angles can be shaped and formed into various angles and curves, allowing for creative and unique designs in architectural sculptures and installations. Additionally, steel angles can be finished with different coatings or paints to enhance their aesthetic appeal and protect them from corrosion, making them a suitable choice for both indoor and outdoor installations. Overall, steel angles offer the necessary strength, flexibility, and aesthetic possibilities required for architectural sculptures and installations.

Send your message to us

Low Carbon Prime Steel Equal Angle Bars in High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords