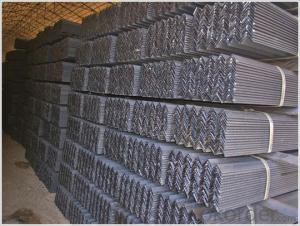

Hot Rolled Steel Angle Bar with High Quality 90*90mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 90*90*7 | 9.656 | 90*90*10 | 13.478 |

| 90*90*8 | 10.946 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used in signage?

- Signage can indeed utilize steel angles. These versatile and durable structural elements can be effortlessly fabricated and installed in a wide range of applications, including signage. With their exceptional strength and stability, steel angles are ideal for supporting heavy or sizable signs. Moreover, they can be joined through welding, bolting, or riveting, facilitating design flexibility and customization. By painting or coating them, their aesthetic appeal can be enhanced while safeguarding against corrosion, thereby guaranteeing the longevity of the signage. In summary, steel angles provide a dependable and sturdy solution for signage installations.

- Q: Can steel angles be used for structural support?

- Yes, steel angles can be used for structural support. Steel angles are often used as beams, columns, or braces in construction projects due to their strength and load-bearing capabilities. They provide stability and rigidity to the structure, making them suitable for supporting heavy loads and withstanding various forces.

- Q: Can steel angles be used in earthquake-prone areas?

- Yes, steel angles can be used in earthquake-prone areas. Steel is a highly durable and strong material that can withstand seismic forces better than other construction materials like wood or concrete. Steel angles, in particular, are commonly used in seismic-resistant designs, as they provide structural support and help distribute the seismic forces throughout the building. Steel angles are designed to resist bending and twisting, making them ideal for earthquake-resistant construction. They are often used in the construction of steel moment frames, which are known for their ability to absorb and dissipate seismic energy. These frames provide a rigid structural system that helps to prevent the collapse of buildings during earthquakes. Furthermore, steel angles can be easily bolted or welded together, allowing for quick and efficient construction. This flexibility in design and construction makes steel angles a popular choice for earthquake-prone areas, where buildings need to be able to withstand high-intensity seismic events. However, it is important to note that the effectiveness of steel angles in earthquake-prone areas also depends on various factors, such as the specific building design, the quality of materials used, and adherence to building codes and regulations. Proper engineering and design considerations should always be followed to ensure the safe and reliable use of steel angles in such areas.

- Q: What are the common design codes and standards for steel angles?

- The specific application and industry requirements determine the common design codes and standards for steel angles. Various recognized design codes and standards are applicable to steel angles, including: 1. The American Institute of Steel Construction (AISC) offers design specifications and standards for structural steel construction, including angles. The AISC Steel Construction Manual provides guidance on designing steel structures and selecting steel angles. 2. The American Society for Testing and Materials (ASTM) develops and publishes technical standards for different materials, including steel. ASTM A36/A36M is a commonly referenced standard for carbon structural steel, including angles. It specifies requirements for chemical composition, mechanical properties, and testing methods. 3. The European Norm (EN) specifies technical delivery conditions for structural steel products. EN 10025-2 covers non-alloy structural steels, including angles, and provides requirements for chemical composition, mechanical properties, and tolerances. 4. The British Standards Institution (BSI) publishes standards related to steel angles, such as BS EN 10056-1. This standard details the dimensions and tolerances for hot-rolled equal and unequal steel angles. 5. The Canadian Standards Association (CSA) provides guidance for steel design and construction in Canada. CSA G40.21 is a widely used standard that covers requirements for general structural steel, including angles. It is important to note that these examples represent common design codes and standards for steel angles. Depending on the project and location, additional local or industry-specific codes and standards may need to be considered. Consulting a structural engineer or referring to relevant design codes and standards is crucial for ensuring compliance and safety in steel angle design and construction.

- Q: Can steel angles be used in earthquake-resistant construction?

- Indeed, earthquake-resistant construction can incorporate steel angles. Due to their exceptional strength and durability, steel angles are frequently employed as structural elements in buildings. In earthquake-resistant construction, steel angles serve the purpose of offering supplementary bracing and reinforcement to the structural system of the building. Through strategic placement, such as at the corners or edges, steel angles aid in the more efficient distribution of earthquake forces and mitigate the risk of structural failure. Moreover, steel angles can be utilized to construct moment-resisting frames or as part of a steel moment frame system, which is highly effective in withstanding lateral forces during an earthquake. In summary, steel angles play a vital role in enhancing a building's seismic performance and are a valuable asset in earthquake-resistant construction.

- Q: What are the different test methods used to evaluate steel angles?

- There are several test methods used to evaluate steel angles in order to ensure their quality and suitability for various applications. These test methods include: 1. Tensile Test: This test measures the tensile strength, yield strength, and elongation properties of the steel angles. It involves applying a gradually increasing load to a specimen until it reaches its breaking point, allowing for assessment of the material's ability to resist forces without deforming or breaking. 2. Bend Test: The bend test evaluates the flexibility and ductility of steel angles. A specimen is bent to a specific angle and assessed for any signs of cracking, fracture, or deformation. This test is crucial in determining the angles' ability to withstand bending forces without compromising their structural integrity. 3. Charpy Impact Test: This test measures the impact resistance and toughness of steel angles by subjecting a notched specimen to a high-velocity impact. The amount of energy absorbed during the impact is measured, indicating the material's ability to resist sudden loads or shocks. 4. Hardness Test: The hardness test determines the steel angle's resistance to indentation or scratching. Different methods such as Rockwell, Brinell, or Vickers hardness tests may be employed to evaluate the material's hardness properties, which can help assess its durability and wear resistance. 5. Ultrasonic Testing: Ultrasonic testing uses high-frequency sound waves to detect flaws or defects within the steel angles. This non-destructive test method allows for the identification of internal cracks, voids, or inclusions that may affect the material's structural integrity. 6. Dimensional Inspection: This test method involves measuring the dimensions, tolerances, and geometric properties of the steel angles. It ensures that the angles meet the required specifications and can provide accurate information for engineering calculations and fabrication processes. By utilizing these various test methods, manufacturers, engineers, and quality control personnel can assess the mechanical properties, structural integrity, and overall quality of steel angles, ensuring their suitability for specific applications.

- Q: How do steel angles perform in terms of sound insulation?

- Steel angles are not typically recognized for their ability to provide sound insulation. This is due to their inflexible and compact composition, which limits their capacity to absorb or diminish sound waves. Consequently, they do not offer significant sound insulation on their own. Nevertheless, when utilized alongside materials like acoustic insulation, steel angles can contribute to the overall sound insulation of a structure. Moreover, the thickness and design of the steel angles can also influence their sound insulation performance. In general, while steel angles may not possess exceptional sound insulation properties, they can still play a role in enhancing the overall soundproofing of a building when employed in conjunction with other soundproofing materials.

- Q: What are the different types of steel angles used in machinery?

- There are several different types of steel angles that are commonly used in machinery. One of the most common types is the equal-leg angle, also known as L-shaped or L-angle steel. This angle has equal dimensions on both sides, forming a 90-degree angle. It is commonly used in machinery to provide structural support and stability, as well as to reinforce joints and connections. Another type is the unequal-leg angle, which has different dimensions on each side, resulting in an uneven angle. This type of angle is often used in machinery where specific weight distribution or load-bearing requirements need to be met, as it allows for greater flexibility in design. Additionally, there are also rounded steel angles, also known as rounded corner angles or round bars. These angles have rounded edges instead of sharp corners, making them ideal for machinery applications where safety is a concern, as they reduce the risk of injury from sharp edges. Furthermore, there are slotted steel angles, which have one or more holes or slots along their length. These slots allow for easy adjustment and mounting of components, making them suitable for machinery that requires frequent modifications or customization. Lastly, stainless steel angles are another type commonly used in machinery. Stainless steel offers excellent corrosion resistance, making it ideal for machinery that operates in harsh or corrosive environments, such as marine or chemical applications. Overall, the choice of steel angle in machinery depends on the specific requirements of the application, including structural needs, load-bearing capacity, safety considerations, and environmental factors.

- Q: How do steel angles contribute to sustainable construction?

- Steel angles contribute to sustainable construction in multiple ways. Firstly, steel is an incredibly durable and long-lasting material, which means that structures built using steel angles will have a longer lifespan compared to those made with other materials. This reduces the need for frequent repairs or replacements, thus minimizing waste and reducing the overall environmental impact of construction. Secondly, steel is a highly recyclable material. At the end of a structure's life cycle, steel angles can be easily recycled and repurposed for other construction projects. This reduces the demand for new steel production, which is energy-intensive and can result in significant carbon emissions. Additionally, steel angles offer design flexibility, allowing architects and engineers to create more efficient and innovative structures. This can lead to optimized building designs that require less energy for heating, cooling, and maintenance, contributing to energy savings and reduced greenhouse gas emissions. Moreover, steel angles are lightweight yet incredibly strong, resulting in less material usage and reduced transportation costs. As a result, the overall carbon footprint associated with steel construction is lower compared to other materials. Furthermore, steel angles have excellent fire resistance properties, making them a safer choice for construction. This increases the longevity of structures and reduces the risk of damage or destruction during fires. Consequently, the need for rebuilding or reconstructing is reduced, leading to less material waste and environmental impact. In conclusion, steel angles contribute to sustainable construction through their durability, recyclability, design flexibility, energy efficiency, lightweight nature, fire resistance, and overall reduced environmental impact. By incorporating steel angles into construction projects, we can create more sustainable and environmentally friendly structures that benefit both the present and future generations.

- Q: What are the alternatives to steel angles in construction?

- Construction offers various alternatives to steel angles, each with its own advantages and disadvantages depending on the specific application. 1. Aluminum angles provide a lightweight and corrosion-resistant option for outdoor construction projects. They are easily machinable and have good electrical conductivity. However, they may not possess the same strength and load-bearing capacity as steel angles, limiting their suitability for heavy-duty structural applications. 2. Fiberglass angles, on the other hand, offer a lightweight and non-conductive solution that is highly resistant to corrosion and chemical damage. They are commonly used in industries exposed to harsh environments. However, their strength may be inferior to that of steel angles, necessitating additional reinforcement for heavy loads. 3. Carbon fiber angles are known for their lightweight and high-strength properties, making them ideal for weight reduction in critical applications like aerospace and automotive industries. However, they tend to be more expensive than steel angles and require specialized manufacturing techniques. 4. Wood angles, made from hardwood or engineered wood products, present a traditional and cost-effective alternative to steel angles. They are readily available and easy to work with, often used in residential and light commercial construction projects. However, their strength and durability may not match that of steel angles, and they may be prone to warping, cracking, or rotting over time. When selecting an alternative to steel angles, it is crucial to consider the specific requirements of the construction project, including load-bearing capacity, environmental conditions, and budget. Consulting with a structural engineer or construction professional can help determine the most suitable option for each scenario.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 90*90mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords