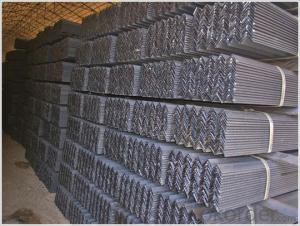

Hot Rolled Steel Angle Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 40*40*3 | 1.852 | 45*45*5 | 3.369 |

| 40*40*4 | 2.422 | 50*50*4 | 3.059 |

| 40*40*5 | 2.976 | 50*50*5 | 3.77 |

| 45*45*4 | 2.736 | 50*50*6 | 4.465 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What are the typical lengths of steel angles?

- Steel angles come in a range of lengths depending on their intended purpose and use. Generally, they are found in standard sizes of 20 feet or 6 meters, which are favored by manufacturers and construction firms for their convenience and easy transport. Moreover, steel angles can be tailored to meet the specific length requirements of a particular project.

- Q: Where can steel angles be purchased?

- Steel angles can be purchased from various sources, including steel suppliers, metal fabrication companies, hardware stores, and online marketplaces such as Amazon or Alibaba.

- Q: What are the common finishes available for steel angles?

- The common finishes available for steel angles include hot-dip galvanized, painted, and untreated/raw.

- Q: Can steel angles be used for shelving and storage racks?

- Yes, steel angles can be used for shelving and storage racks. Steel angles are commonly used in construction and industrial applications due to their strength and durability. They provide excellent support and stability, making them suitable for organizing and storing various items on shelves and racks.

- Q: Can steel angles be used for manufacturing machinery?

- Yes, steel angles can be used for manufacturing machinery. Steel angles provide structural support and can be used as framing members, braces, or brackets in machinery construction. They offer high strength, durability, and versatility, making them suitable for various industrial applications.

- Q: What is the bending capacity of a steel angle?

- The bending capacity of a steel angle refers to its ability to withstand bending or flexing without breaking or deforming excessively. It is a measure of the angle's structural strength and is typically determined by factors such as the dimensions and thickness of the angle, the type of steel used, and any additional reinforcements or supports present. The bending capacity is usually expressed in terms of the maximum amount of load or stress that the angle can endure before it reaches its yield point, which is the point at which it permanently deforms. The bending capacity of a steel angle can vary widely depending on these factors, and it is crucial to consider this capacity when designing and constructing structures that utilize steel angles to ensure their structural integrity and safety.

- Q: What are the different methods of surface preparation for steel angles?

- There are several methods of surface preparation for steel angles in order to ensure proper adhesion of coatings, improve corrosion resistance, and enhance the overall durability of the material. Some of the common methods include: 1. Mechanical Cleaning: This involves using mechanical tools such as wire brushes, sandpaper, or abrasive discs to physically remove dirt, rust, mill scale, and other contaminants from the surface of the steel angles. This method is relatively simple and cost-effective but may not be suitable for heavy corrosion or stubborn deposits. 2. Chemical Cleaning: Chemical cleaning involves the use of acid-based solutions or pickling pastes to dissolve rust, scale, and other contaminants. The solution is applied to the surface and left for a specific period before being rinsed off. This method is highly effective in removing stubborn deposits but requires careful handling and proper disposal of the chemicals. 3. Power Tool Cleaning: Power tool cleaning utilizes power tools like grinders, sanders, or needle guns with abrasive attachments to remove rust, scale, and other contaminants. This method is faster and more efficient than manual mechanical cleaning, making it suitable for large-scale surface preparation. 4. Blast Cleaning: Blast cleaning, also known as abrasive blasting, involves propelling abrasive materials (such as sand, steel grit, or glass beads) at high velocity onto the steel surface using compressed air or centrifugal force. This method effectively removes rust, scale, and other contaminants, providing a clean and profiled surface. It is widely used in industrial applications but requires proper safety measures to protect workers from exposure to abrasive materials. 5. Flame Cleaning: Flame cleaning is a method where a high-temperature flame is directed onto the steel surface to remove contaminants. The intense heat burns off organic materials and evaporates moisture, leaving a clean surface. This method is particularly useful for removing oil, grease, and paint residues. 6. Conversion Coating: Conversion coating involves applying a chemical solution onto the steel surface, which reacts with the metal to form a thin protective layer. This layer enhances the adhesion of subsequent coatings and provides additional corrosion resistance. Common conversion coatings include phosphating, chromating, and passivation. It is important to note that the selection of the most appropriate surface preparation method depends on factors such as the extent of corrosion, the desired coating system, and the environmental conditions the steel angles will be exposed to. Consulting with experts or referring to industry standards can help determine the most suitable method for a specific application.

- Q: How do you calculate the axial compression capacity of a steel angle?

- To calculate the axial compression capacity of a steel angle, you would need to consider several factors such as the dimensions and properties of the angle, the material properties, and the boundary conditions. The calculation typically involves determining the slenderness ratio, which is the ratio of the length of the angle to its thickness. This ratio helps determine whether the angle will fail in compression or buckling. The axial compression capacity can then be calculated using relevant design codes or formulas, taking into account factors such as the yield strength of the material and any additional considerations specific to the application.

- Q: What is the typical length of a steel angle?

- The typical length of a steel angle can vary depending on the specific application or project requirements. However, standard lengths for steel angles often range from 10 to 20 feet.

- Q: Can steel angles be used as support beams?

- Yes, steel angles can be used as support beams in construction and structural engineering projects. They are commonly used for their strength and load-bearing capabilities, providing stability and support to various structures such as buildings, bridges, and frameworks.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches