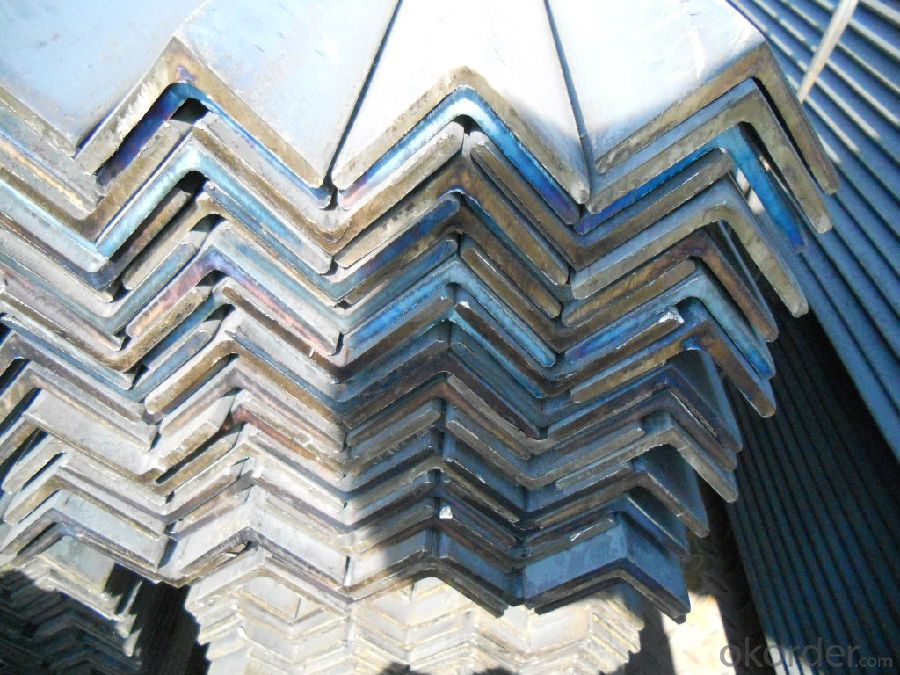

Hot Rolled Steel Angle Bar with High Quality 75*75mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 75*75*6 | 6.905 | 75*75*8 | 9.03 |

| 75*75*7 | 7.976 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used for acoustic isolation or noise barriers?

- No, steel angles are not typically used for acoustic isolation or noise barriers as they do not possess the necessary properties to effectively block or absorb sound. Other materials such as acoustic panels or specialized barriers are more commonly used for this purpose.

- Q: How do you determine the required angle size for a specific application?

- To determine the required angle size for a specific application, you need to consider factors such as the purpose of the application, the type of material being used, and the desired outcome. It is important to analyze the application's requirements, consult relevant guidelines or standards, and consider any potential safety or functional considerations. Additionally, conducting tests or simulations can help determine the appropriate angle size for optimal performance and efficiency in the given application.

- Q: What are the different types of connections used for steel angles?

- Steel angles can be connected in several ways, depending on the application and load requirements. Here are some commonly used connections: 1. Welded Connection: The most frequently used connection for steel angles involves welding them to other members, such as beams or columns. These connections offer high strength and stiffness, making them suitable for heavy loads and structural purposes. 2. Bolted Connection: Another option is to bolt the steel angles to the connected members using bolts and nuts. Bolted connections are preferred when the structure may need to be disassembled or relocated. They offer flexibility, adjustability, and easy installation. 3. Riveted Connection: While not as commonly used nowadays, riveted connections were widely employed in older structures. Riveting involves joining the steel angle to other members using rivets. Although they require skilled labor for installation, riveted connections provide good strength and durability. 4. Clip Connection: A clip connection is a type of bolted connection where a clip or bracket is used to secure the steel angle to the supporting member. This allows for easy assembly and disassembly, making it suitable for temporary structures or situations requiring frequent modifications. 5. Shear Connection: Shear connections use shear plates or angles to connect the steel angle to the supporting member. These connections primarily transfer shear forces and provide sufficient strength and rigidity. 6. Cleat Connection: Cleat connections involve using a cleat plate, typically welded or bolted, to connect the steel angle to the supporting member. Cleat connections are commonly employed in industrial applications where heavy loads and high forces need to be transferred. When selecting the appropriate type of connection for steel angles, it is crucial to consider the specific requirements of the structure, including load capacity, design codes, and environmental conditions. Consulting with a structural engineer or referring to relevant design standards can ensure the proper selection and installation of the connection.

- Q: Can steel angles be used in telecommunications or broadcasting structures?

- Yes, steel angles can be used in telecommunications or broadcasting structures. Steel angles are commonly used in construction due to their strength, durability, and versatility. They can provide structural support and stability to various components of telecommunications and broadcasting structures, such as antenna mounts, equipment racks, and cable trays. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, making them suitable for a wide range of applications in the telecommunications and broadcasting industry.

- Q: Can steel angles be used in sports facilities or stadium constructions?

- Yes, steel angles can be used in sports facilities or stadium constructions. Steel angles are commonly used in construction projects due to their strength and durability. They can be used to provide support and stability in various structural elements, such as beams, columns, and frames, making them suitable for use in sports facilities or stadium constructions where robustness and reliability are crucial.

- Q: How do you calculate the shear force on a loaded steel angle?

- To calculate the shear force on a loaded steel angle, you need to consider the applied load, the geometry of the angle, and the material properties of the steel. The shear force refers to the force acting parallel to the cross-sectional area of the angle. First, determine the applied load that is acting on the steel angle. This could be a concentrated load, distributed load, or a combination of both. It is important to accurately determine the magnitude and location of the load. Next, consider the geometry of the steel angle. The angle has two legs, with each leg having a specific length, width, and thickness. Measure these dimensions accurately. Once you have the load and angle dimensions, you can calculate the shear force using the formula: Shear Force = Load / Cross-sectional Area To calculate the cross-sectional area, you need to consider the shape of the angle. The cross-sectional area of a steel angle is typically calculated as the sum of the areas of the two legs minus the area of the corner radius. If the angle has unequal legs, the cross-sectional area can be calculated as the sum of the areas of the longer and shorter legs minus the area of the corner radius. After calculating the cross-sectional area, divide the applied load by this value to obtain the shear force on the loaded steel angle. It is important to note that the above calculation assumes the steel angle is subjected to pure shear. In practical situations, other factors such as bending moments and torsion may also need to be considered, which would require more complex calculations and analysis. Therefore, it is advisable to consult relevant design codes, structural engineering principles, or seek the advice of a professional engineer for accurate and reliable results.

- Q: Can steel angles be used for load-bearing walls?

- Yes, steel angles can be used for load-bearing walls. Steel angles are commonly used in construction as a structural element to provide support and stability. They are often used to reinforce load-bearing walls by adding strength and rigidity. Steel angles can be used to distribute the weight of a load evenly, making them suitable for load-bearing applications. However, it is important to ensure that the steel angles are appropriately designed and installed to meet the specific load requirements of the wall. Consulting with a structural engineer or construction professional is recommended to ensure the proper use of steel angles for load-bearing walls.

- Q: What are the different types of connections used for steel angles in residential applications?

- There are several different types of connections used for steel angles in residential applications. Some of the most commonly used ones include: 1. Welded connections: This is the most common type of connection used for steel angles. It involves welding the angle to the adjacent structural members, such as beams or columns. Welded connections provide excellent strength and rigidity, making them ideal for residential applications. 2. Bolted connections: Bolted connections involve using bolts and nuts to secure the steel angle to the adjacent members. This type of connection is often used when the angle needs to be easily removable or adjustable. Bolted connections are less rigid than welded connections but still provide sufficient strength for residential applications. 3. Clip connections: Clip connections are typically used to connect steel angles to wood or other non-steel materials. They involve using clips or brackets that are attached to the angle and then fastened to the adjacent material using screws or nails. Clip connections are commonly used in residential framing applications. 4. Gusset plate connections: Gusset plate connections are used when two steel angles need to be connected at a joint. A gusset plate, which is a flat plate of steel, is welded or bolted to the angles to provide additional support and rigidity. This type of connection is often used in residential roof trusses and other structural applications. 5. Cleat connections: Cleat connections involve using a steel plate, called a cleat, that is bolted or welded to the steel angle and the adjacent member. Cleat connections are commonly used when the angle needs to be attached to a horizontal member, such as a floor or roof joist. These are just a few examples of the different types of connections used for steel angles in residential applications. The choice of connection type will depend on factors such as the structural requirements, ease of installation, and the type of materials being connected.

- Q: How do steel angles perform under impact or dynamic loading conditions?

- Steel angles are known for their excellent performance under impact or dynamic loading conditions. Their shape provides structural stability and resistance to bending, making them highly effective in withstanding sudden forces and vibrations. The high strength of steel angles allows them to absorb energy and distribute it evenly, reducing the risk of deformation or failure. Overall, steel angles are reliable and dependable in demanding situations with impact or dynamic loading.

- Q: What is the maximum length for a steel angle bracket?

- The maximum length for a steel angle bracket can vary depending on the manufacturer and the specific design of the bracket. However, in general, steel angle brackets are commonly available in lengths ranging from 1 inch to 8 feet or more. It's important to note that longer brackets may be more prone to bending or flexing under heavy loads, so it's essential to consider the intended application and weight-bearing requirements when selecting the appropriate length for a steel angle bracket. Additionally, consulting the manufacturer's guidelines and specifications is recommended to ensure the bracket's maximum length is not exceeded, as this could compromise its structural integrity.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 75*75mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords