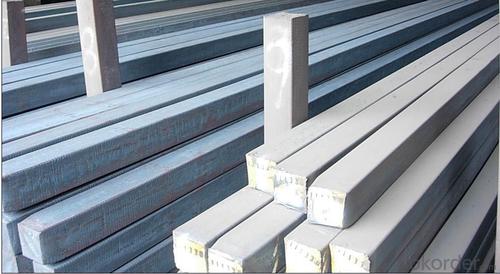

Hot Rolled Square Steel Billet 3SP Standard 110mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Hot Rolled Square Steel Billet 3SP Standard 110mm

Description of Hot Rolled Square Steel Billet 3SP Standard 110mm

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling. Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

Main Feature of Hot Rolled Square Steel Billet 3SP Standard 110mm

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve.

Applications of Hot Rolled Square Steel Billet 3SP Standard 110mm

1) Automotive bodies: filters, fuel tanks, etc.

2) Construction materials: roofings, welding pipes,

3) Electric and electronic appliances: computer cans, etc.

4) Steel cans: containers, etc.

5) Steel furniture: washing machines, refrigerators, microwaves, etc.

6) Drums

7) Office equipment: printer, recorders, etc.

8) Motors and transformers

Specifications of Hot Rolled Square Steel Billet 3SP Standard 110mm

| Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

| N/mm2 | Nominal Thickness mm (t) | |||||||

| JIS | Yogic | 0.25-0.4 | 0.4-0.6 | 0.6-1.0 | 1.0-1.6 | |||

| G3312 | specification | |||||||

| CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

| CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

| --- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

| CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

| CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

| CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

| CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

| ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

| ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

| A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

| A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

| A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

| A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

| A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

| A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

| A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

| A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ of Hot Rolled Square Steel Billet 3SP Standard 110mm

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

1, ISO, BV, CE, SGS approved.

2, Competitive price and quality.

3, Efficient service team online for 24 hours.

4, Smooth production ability(50000tons/month) .

5, quick delivery and standard exporting package.

6, Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc .

- Q: What are the specifications for alloy steel billets used in the aerospace industry?

- The specifications for alloy steel billets used in the aerospace industry can vary depending on the specific application and requirements. However, there are certain general specifications that are commonly followed. Firstly, the alloy steel billets used in the aerospace industry must meet stringent material standards such as the Aerospace Material Specification (AMS) and the International Organization for Standardization (ISO) standards. These standards ensure the material's mechanical properties, chemical composition, and overall quality meet the demanding requirements of the aerospace industry. In terms of mechanical properties, the alloy steel billets should possess high strength, excellent toughness, and good fatigue resistance. These properties are essential to withstand the extreme conditions and stress experienced by aircraft components during their operation. Additionally, the chemical composition of the alloy steel billets must be carefully controlled to ensure the desired alloying elements are present in the appropriate ratios. Common alloying elements used in aerospace grade steels include chromium, molybdenum, nickel, and vanadium. These elements enhance the material's strength, corrosion resistance, and heat resistance. Furthermore, the alloy steel billets must undergo specific heat treatment processes to achieve the desired microstructure and mechanical properties. Heat treatments such as quenching and tempering, solution annealing, and precipitation hardening are commonly employed to optimize the material's strength, hardness, and ductility. The size and shape of the alloy steel billets also play a crucial role in their usability. They are typically manufactured in various cross-sectional shapes, including round, square, and rectangular, to cater to different aerospace component designs. The billets should be produced with precise dimensions and tight tolerances to ensure compatibility with the manufacturing processes and facilitate the production of high-quality aerospace components. Overall, the specifications for alloy steel billets used in the aerospace industry prioritize high mechanical strength, excellent toughness, strict chemical composition control, precise dimensions, and tailored heat treatment processes. These stringent requirements ensure that the alloy steel billets meet the demanding performance and safety standards required in the aerospace industry.

- Q: How are steel billets used in the manufacturing of power plant equipment?

- Due to their exceptional strength and durability, steel billets play a vital role in the production of power plant equipment. These billets serve as the primary material from which various parts and components necessary for power plant machinery are shaped and formed. One significant application of steel billets in power plant equipment manufacturing is the fabrication of turbine blades. These blades are exposed to high temperatures, immense pressures, and rotational forces. Steel billets are carefully chosen for their mechanical properties, such as high tensile strength and resistance to corrosion and fatigue, to ensure the blades can withstand the demanding operating conditions. Additionally, steel billets are employed in the production of generator rotors and stators. These components convert mechanical energy into electrical energy. The strength and stability of steel billets enable them to endure the intense magnetic fields and rotational forces generated by the generator, guaranteeing reliable and efficient power generation. Furthermore, steel billets are used in the manufacturing of boilers and pressure vessels, which are vital for the power generation process. These vessels endure high pressures and temperatures, and steel billets with outstanding heat resistance and pressure containment properties are utilized to ensure the safety and dependability of the power plant equipment. In conclusion, the superior strength, durability, and resistance to extreme conditions make steel billets indispensable in the manufacturing of power plant equipment. Whether it be for turbine blades, generator components, or pressure vessels, steel billets play a critical role in ensuring the reliable and efficient operation of power plants.

- Q: What are the different types of steel billet surface treatments?

- There are several different types of steel billet surface treatments, including pickling, shot blasting, and painting. Pickling involves removing impurities and oxides from the surface of the billet using an acid solution. Shot blasting is a process in which small metallic or abrasive particles are blasted onto the surface of the billet to remove rust, scale, and other contaminants. Painting involves applying a protective coating or layer of paint to the surface of the billet to prevent corrosion and improve its appearance.

- Q: How are steel billets used in the production of rebar?

- Steel billets are used as the primary raw material in the production of rebar. These billets are heated and then passed through a series of rollers to shape them into long, thin rods. The resulting rebar is widely used in construction and infrastructure projects to reinforce concrete structures and provide added strength and durability.

- Q: What is the standard size of a steel billet?

- The standard size of a steel billet can vary depending on the specific requirements and industry standards. However, in general, steel billets are typically rectangular in shape and have dimensions ranging from 100mm x 100mm to 200mm x 200mm. The length of a steel billet can also vary but is commonly around 6 meters. It is important to note that these dimensions are not fixed and can be customized based on the intended use and manufacturing process.

- Q: How do steel billets contribute to the overall strength of a finished product?

- The strength of the finished product heavily relies on the quality of the steel billets used. Steel billets form an essential part of the manufacturing process for various steel products and have a vital role in determining the final product's strength. To start with, steel billets are produced by continuously casting molten steel into solid blocks or forms. This casting method guarantees that the steel billets possess a consistent and uniform structure, which is crucial for maintaining the overall strength of the end product. The uniformity of the billets enables an even distribution of stress and load-bearing capacity throughout the final product. Furthermore, steel billets are typically made from high-quality steel alloys specifically selected for their superior strength properties. These alloys contain elements like carbon, manganese, and other alloying elements that enhance the overall strength and hardness of the steel. The utilization of high-quality steel billets enables manufacturers to create finished products with excellent tensile and yield strength, making them highly resistant to deformation, bending, and breaking. In addition, steel billets undergo various heat treatment processes such as quenching and tempering, which further enhance their strength. Quenching involves rapid cooling of the billets to increase their hardness, while tempering reduces brittleness and improves toughness. These heat treatment processes result in steel billets with improved mechanical properties, including higher yield strength and enhanced resistance to fatigue and impact. Moreover, the size and shape of steel billets also contribute to the overall strength of the finished product. The dimensions of the billets determine the final dimensions of the product, and larger billet sizes allow for a more significant and stronger end product. Similarly, optimizing the shape of the billets improves the load-bearing capacity and structural integrity of the finished product. To conclude, steel billets are crucial for the overall strength of the finished product. Through their uniform structure, high-quality alloys, heat treatment processes, and optimized size and shape, steel billets provide the necessary foundation for the production of robust and long-lasting steel products. Selecting the appropriate steel billets and ensuring their quality throughout the manufacturing process are essential steps in creating a finished product with exceptional strength and performance.

- Q: How are steel billets used in the production of fasteners?

- Steel billets are used in the production of fasteners as they serve as the raw material for manufacturing various types of fasteners such as bolts, screws, and nuts. These billets are heated and then forged or rolled to shape them into the desired fastener form. The resulting fasteners possess high strength and durability, making them suitable for a wide range of applications in industries like construction, automotive, and manufacturing.

- Q: Can steel billets be used in the production of appliances?

- Appliances can indeed utilize steel billets for their production. These semi-finished products are typically employed for subsequent processing into diverse forms and dimensions. In the context of appliances, steel billets can serve as the primary material for fabricating elements like frames, panels, and other structural components. Steel possesses remarkable versatility and durability, providing robustness, stability, and corrosion resistance, thereby rendering it appropriate for appliances requiring sturdy construction. Moreover, steel can be effortlessly molded and shaped to fulfill the distinct design requisites of various appliances, making it the preferred choice in the manufacturing procedure.

- Q: What are the different sizes of steel billets?

- The sizes of steel billets can vary depending on the specific requirements and industry standards. However, common sizes range from small billets measuring around 100mm by 100mm to larger ones measuring several meters in length and width.

- Q: Are steel billets recyclable?

- Steel billets can indeed be recycled. As one of the most widely recycled materials globally, steel has a well-established and remarkably efficient recycling process for its billets. When these billets reach the end of their usefulness, they can be melted and repurposed to create new steel products. By engaging in this recycling process, we not only conserve precious natural resources but also decrease energy consumption and minimize our environmental footprint. Moreover, recycling steel billets aids in diminishing landfill waste while supporting the circular economy and promoting the sustainable utilization of resources.

Send your message to us

Hot Rolled Square Steel Billet 3SP Standard 110mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords