Hot Rolled Spring Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 600000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Spring Steel:

Spring steel is divided into two types, one is alloy spring steel, and other one is carbon spring steel.

Alloy spring steel is a type that is used for manufacturing springs and other elastic parts. Spring steel should have high elastic limit and ratio of yield strength and tensile strength to make sure that the springs obtain enough power of elastic deformation and can bear much load.

Types of alloy spring steel: Si-Mn spring steel, Si-Cr spring steel, Cr-Mn Spring steel, Cr-V spring steel and so on.

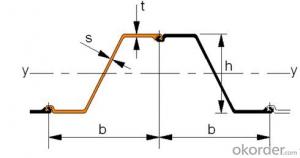

Specification of Hot Rolled Spring Steel

-Material: 55CrMnA

-Standard: GB/T 1222-1984

-Type: Spring Steel

Corresponding Steel Grade for Reference:

CHN, GB | JPN, JIS | GER, DIN |

55CrMnA | SUP9 | 55Cr3 |

GBR, BS | FRA,FN | |

525A58 | 55Cr3 |

Chemical Composition:

C | Si | Mn |

0.52~0.60 | 0.17~0.37 | 0.65~0.95 |

S | P | Cr |

≤0.030 | ≤0.030 | 0.65~0.95 |

Ni | Cu | V |

≤0.35 | ≤0.25 | 0.10~0.20 |

Mechanical Properties:

-Tensile Strength σb (MPa): ≥1225(125)

-Yield Strength σs (MPa): ≥1080 (110)

-Percentage reduction of area: ψ (%): ≥20

-Hardness:

1, Hot rolled, ≤321HB

2, Cold drawn + Heat treatment: ≤321HB

-Norm of heat treatment:

1, Quenching: 830℃~860℃.

2, Cooled by oil.

3, Tempering: 460℃~510℃.

Usage/Applications of Hot Rolled Spring Steel

-55CrMnA Spring Steel possesses high strength, plasticity and toughness. Its hardenability is good. The thermal sensitivity is lower than Mn-steel. The decarburizing tendency is smaller than Si-Mn steel. The outstanding characteristic is the nice hardenability, moreover, hot workability, general mechanical properties and anti-decarburizing are also good.

-It’s used for producing large flat spring o spiral spring with big diameter that can bear much load in the industry of cars and tractors.

Packaging & Delivery of Hot Rolled Spring Steel:

-Packing Detail:

1, The products can be packed in bundles by steel wires.

2, The weight of each bundle no exceed normally 3 tons

-Marks: there are two types of marks.

1, Tag marks. To show customers the specifications of products, company name and logo and other information required by customers.

2, Color marks. It’s easy for customers to distinguish them from other products at destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Terms of payment: T.T. or L/C at sight.

Photos of Hot Rolled Spring Steel:

- Q: Can special steel be used in the automotive parts manufacturing industry?

- Yes, special steel can be used in the automotive parts manufacturing industry. Special steel, such as high-strength, heat-resistant, or corrosion-resistant alloys, can provide enhanced durability, performance, and safety in automotive components like engine parts, suspension systems, and body structures. The use of special steel can improve the overall quality and longevity of automotive parts, ensuring better performance and reliability of vehicles.

- Q: How does stainless steel contribute to the automotive industry?

- Stainless steel contributes to the automotive industry by providing strength, durability, and corrosion resistance in various automotive components such as exhaust systems, body panels, and engine parts. Its ability to withstand extreme temperatures and harsh conditions make it a preferred material for manufacturing high-performance vehicles. Additionally, stainless steel's aesthetic appeal and low maintenance requirements make it suitable for decorative purposes in car interiors and exteriors.

- Q: What are the challenges in machining special steel alloys?

- Machining special steel alloys poses several challenges due to their unique properties and characteristics. One of the primary challenges is their high hardness. Special steel alloys are often heat-treated to enhance their mechanical properties, resulting in increased hardness. This makes it difficult to machine them as traditional cutting tools may wear out quickly or become dull. The high hardness also increases the risk of tool breakage, leading to frequent tool changes and increased production downtime. Another challenge is the presence of abrasive elements in special steel alloys. Some alloys contain elements like chromium, tungsten, or vanadium, which can cause rapid tool wear and degradation. These abrasive elements can cause excessive tool wear, leading to reduced cutting tool life and increased machining costs. Moreover, the presence of these elements can result in poor surface finish and dimensional accuracy if not properly managed during the machining process. Special steel alloys also tend to have low thermal conductivity, which makes it difficult to dissipate heat generated during machining. This can lead to high temperatures at the cutting zone, resulting in thermal expansion and distortion of the workpiece. The heat can also affect the cutting tool, reducing its life and efficiency. Managing the heat generated during machining is critical to prevent workpiece deformation and maintain dimensional accuracy. Furthermore, the presence of alloying elements can make these steel alloys prone to work hardening. This means that the material becomes harder and more difficult to cut as the machining process progresses. Work hardening can lead to increased cutting forces, tool wear, and reduced surface finish. To overcome this challenge, machining parameters such as cutting speed, feed rate, and depth of cut must be carefully optimized to avoid excessive work hardening. In conclusion, machining special steel alloys presents challenges such as high hardness, abrasive elements, low thermal conductivity, and work hardening. Overcoming these challenges requires the use of specialized cutting tools, efficient cooling and lubrication systems, optimized machining parameters, and careful selection of machining strategies. By addressing these challenges effectively, manufacturers can achieve accurate and efficient machining of special steel alloys.

- Q: How is precipitation-hardening steel used in aerospace applications?

- Precipitation-hardening steel is commonly used in aerospace applications due to its exceptional strength-to-weight ratio and excellent corrosion resistance. It is extensively used in critical components such as aircraft structural parts, landing gear, engine components, and fasteners. The precipitation hardening process involves heating and cooling the steel to create a fine dispersion of precipitates, which significantly enhances its mechanical properties. This steel's high strength allows for the construction of lighter and more fuel-efficient aircraft, while its corrosion resistance prolongs the lifespan of aerospace components, ensuring safe and reliable operation.

- Q: How does special steel contribute to reducing product downtime?

- Special steel contributes to reducing product downtime by offering enhanced durability and resistance to wear, corrosion, and high temperatures. Its unique properties enable components made from special steel to withstand harsh operating conditions and maintain their integrity over extended periods. By using special steel in critical parts, manufacturers can minimize the frequency of component failures, repairs, and replacements, thereby reducing product downtime and increasing overall productivity.

- Q: What are the main alloying elements in special steel?

- The main alloying elements in special steel are chromium, nickel, molybdenum, vanadium, and tungsten.

- Q: How does special steel contribute to the aerospace structural industry?

- Special steel plays a crucial role in the aerospace structural industry by offering exceptional strength, durability, and heat resistance. It is used extensively in the manufacturing of aircraft components such as landing gears, engine parts, and structural frames. The high tensile strength and corrosion resistance of special steel ensure the integrity and safety of the aircraft, enabling it to withstand extreme conditions and stress encountered during flight. Additionally, special steel's lightweight nature allows for increased fuel efficiency, reducing operational costs and environmental impact in the aerospace industry.

- Q: How does special steel contribute to the metalworking industry?

- The metalworking industry greatly relies on special steel to achieve properties and performance that regular steel cannot. Special steel plays a vital role in several ways: 1. Strengthened and Lasting: Through the use of specific alloys and composition, special steel is manufactured to be stronger and more durable than regular steel. This allows it to withstand high temperatures, heavy loads, and extreme environments, making it perfect for aerospace, automotive, and construction industries. 2. Improved Resistance to Corrosion: Special steel is designed to have superior resistance to corrosion compared to regular steel. This makes it highly suitable for marine, chemical, and oil and gas industries, where exposure to harsh environments and corrosive elements is common. 3. Increased Hardness and Resistance to Wear: Special steel can be engineered to have higher hardness and resistance to wear, making it ideal for manufacturing cutting tools, dies, molds, and other components that require prolonged usage and resistance to wear and tear. This contributes to increased productivity and efficiency in metalworking processes. 4. Precise Machining: Special steel offers excellent machinability, allowing for precise shaping, drilling, and cutting. This enables manufacturers to easily create complex and intricate designs, resulting in high-quality finished products and components. 5. Customization and Flexibility: Special steel can be customized to meet specific requirements, allowing for flexibility in design and application. Manufacturers have a wide range of special steel grades to choose from, each with its unique properties, to suit their specific needs. Overall, special steel significantly contributes to the metalworking industry by providing enhanced strength, durability, corrosion resistance, hardness, wear resistance, machinability, and customization options. It enables the industry to manufacture high-quality products, improve efficiency, and meet the demanding requirements of various sectors.

- Q: How does special steel contribute to improving product quality?

- Special steel contributes to improving product quality in several ways. Firstly, special steel has superior strength and durability compared to ordinary steel, making it less likely to deform or break under stress. This ensures that products made with special steel have a longer lifespan and are more reliable for consumers. Secondly, special steel can be engineered with specific properties such as corrosion resistance, heat resistance, or high hardness, which are essential for certain industries or applications. This allows manufacturers to create products that can withstand harsh environments or demanding conditions, ultimately enhancing product quality. Lastly, special steel can be precision-machined to tight tolerances, enabling the production of complex and intricate components with high precision. This level of accuracy results in better-fitting parts, improved performance, and enhanced overall product quality.

- Q: How does special steel contribute to the aerospace material weight reduction?

- Special steel contributes to aerospace material weight reduction by providing a lightweight yet strong and durable material option. Its unique properties, such as high strength-to-weight ratio and excellent corrosion resistance, allow for the construction of lighter aircraft components without compromising on safety or performance. This reduction in weight leads to improved fuel efficiency, increased payload capacity, and enhanced maneuverability, making special steel an essential element in aerospace industry's ongoing efforts to achieve greater fuel economy and sustainability.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

Hot Rolled Spring Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 600000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords