High Speed Laminatings Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Speed Laminatings Hot Press Machine

Products detail

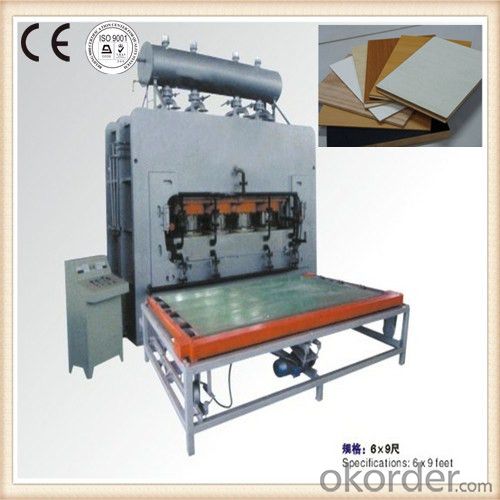

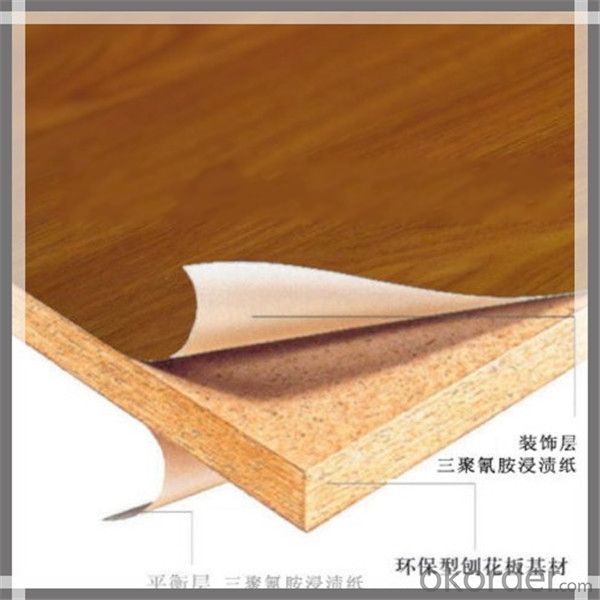

High speed laminatings hot press machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

High speed laminatings hot press machine is availale according to your requirements!

Features

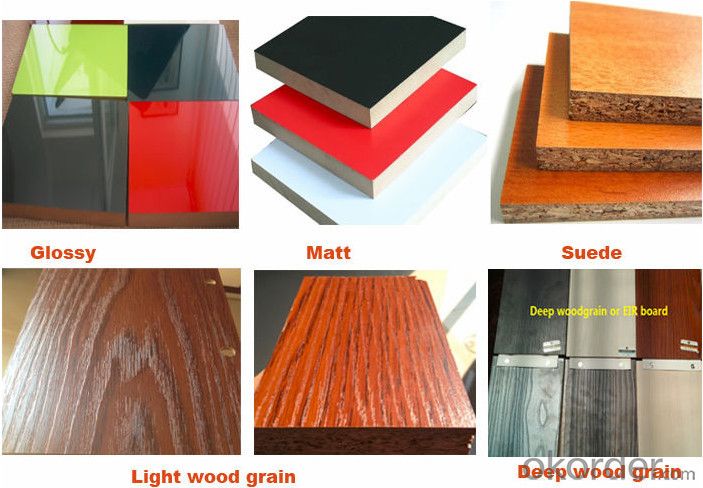

High speed laminatings hot press machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (High speed laminatings hot press machine are for)

- High speed laminatings hot press machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

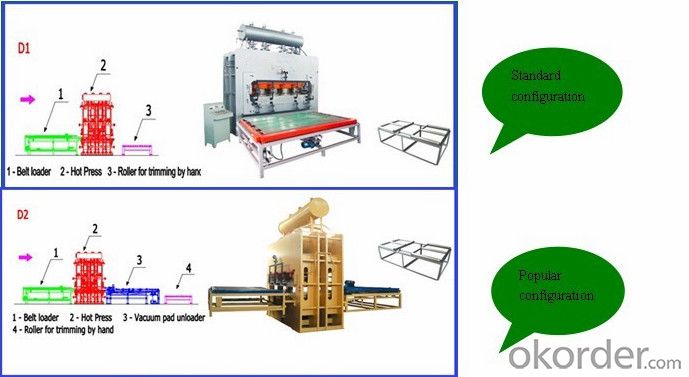

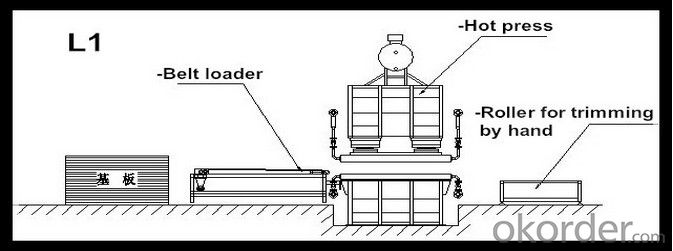

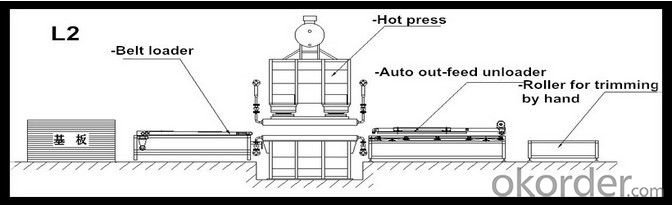

High speed laminatings hot press machine Production line A&B

Specification

The technical parameters of High speed laminatings hot press machine :

| Type | Size (ft) | Nominal Pressure (KN) | End Panel Size (mm) | Working Pressure (kg/cm2) | Main oil cylinder (Diameter×Quantity) |

| NYJ-900T | 4×8 | 9000 | 1220×2440 | ≤30 | Φ280×6 |

| NYJ-1200T | 4×8 | 12000 | 1220×2440 | ≤40 | Φ320×6 |

| NYJ-1400T | 4×8 | 14000 | 1220×2440 | ≤47 | Φ340×6 |

| 5×8 | 1550×2440 | ≤37 | Φ340×6 | ||

| 6×8 | 1830×2440 | ≤31 | Φ340×6 | ||

| NYJ-1600T | 4×8 | 16000 | 1200×2440 | ≤53 | Φ380×6 |

| 4×9 | 1200×2750 | ≤47 | Φ380×6 | ||

| 5×8 | 1500×2440 | ≤42 | Φ380×6 | ||

| 7×9 | 2100×2750 | ≤27 | Φ380×6 | ||

Products display

Packing & Shipping

Package: High speed laminatings hot press machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

Q:How to control the quality ?

A:Inform you the new progress of the production in some certain time. You will clear imagine how yourmachine made from the raw material step by step.To make sure our salesman be your eyes and ears.

The Ex-work test. The ex-work including the Final assembly test, factory test and working performance test. Each machine no matter big or small must pass the Ex-work work before leaving the factory. We must gurantee everyone machine from CNBM workshop must be qualified . The vedio will be taken for the test, and welcome you to come to our factory for inspection.

Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: i see people doing an incline and some lying flat on theri back doing a flat bench press. does it excerise different muslcles or just works the same and its just for comfort? and what the difference also on the bench press machine where the stack of weights are behind your head?

- the incline makes it harder for yourself but works the muscles harder which will bring better faster results ! the machine with the weights behind you works completly different muscles this is all down to your own personal preference on what you want out of your exercise and what muscles you want to work ! i hope this has helped

- Q: so which bench press will help give you the most strength in your chest? could you also tell me how to combo them in a workout, like flat to decline or decline to incline.

- Thers absolutely no right or wrong way to combo bench presses! actually the more you vary it the better! I guess the flat is the best for overall strength, but its good to mix it up and try different angles at which you put pressure on the pectorial muscle! This way you can keep track on prograssion in multiple ways! So just do whatever you want in which ever order, keep the body guessing! Also play around with the sets and reps im sure you can appreciate between buildin size and sterngth bit it good to vary it from now and again!

- Q: I'm 16 I weight 9 stone 6 pounds how many press ups and reps should I do to get a bigger chest?

- Pushups or press ups are a calisthenic exercise and mosts people can rapidly improve to the point that they can churn out lots of repetitions. In which case there is no longer enough resistance going on to allow you to get a bigger chest. If you want to increase muscular size, you need to do progressive resistance exercise...Weight lifting where you can constantly increase the weight as you grow stronger. Updog is right in that you may become more defined, but that's about it....

- Q: What happens when our Free Press is hijacked by Free Money?

- I think most of us have a love /hate relationship with the press, but a free press is one of THE most important things of a democracy........We need to make sure they stay on the level so we know what the hell is going on..........

- Q: If only one press is used, it takes the older press twice as long to print an edition as it takes the newer press. If the two presses together can print an edition in 3 hr, how long will it take each press alone to print an edition?

- Let x denote the older press's publishing rate (in editions/hr). Then the newer press's publishing rate is 2x (ed/hr). If the two presses work together for 3 hours, they produce 1 edition. 3(x + 2x) = 1 9x = 1 x = 1/9 So the older press does 1/9 of an edition per hour when working by itself, and the newer press does 2/9 of an edition in an hour. So the older press would take 9 hr to do 9/9 of an edition, and the newer press would take half that time, of 4.5 hr.

- Q: I called the cops on my ex becuase we were involved in an argument and he hit me, I called the police in July 2009 and he was arrested and charged with assault/domestic violence at the time I did not press any charges, as of now the case is still open and he is on probation, can I still press charges if I want to?

- Someone pressed charges as he is on probation. Usually the police do under the law since most states do not require someone to press charges other than the police. If charged once, charging him again is unconstitutional. Moreover, this is probably a misdemeanor assault and the Statute of Limitations is 1 year. Too late.

- Q: Ok, about a few days ago i hit this preppy girl and the face and she didnt fight back she just fell down and cried. The next day I got suspended from school and the hoe's mom said she was gonna press charges, My principal talked her out of it. So 3 days later when I came back I said Hi to her twice and she didn't answer me so I said I f/ing said hi to you b/ answer me. Then I walked up to her and said you do you remember that time I hit you in the face? So later that day she went home because she thought I was gonna hit her again. So my principal takes me out of class and said that her mom is considering pressing charges because she found out what I said. My principal said that she could press charges until 30 days after I hit her. Would she still be able to press charges, or not?

- Yes and she should.

- Q: I have a 1995 Honda Accord...I had a friend change my brakes and rotors - But to find out he couldnt change the rotors, Cuz they are pressed on....I told another guy mechanic that says he is able to get them off - Is there a way he can, I dont want to be left witht he same problem then have to go take it to a shop and spend 3 times as much.

- This Site Might Help You. RE: Pressed rotors on a honda accord? I have a 1995 Honda Accord...I had a friend change my brakes and rotors - But to find out he couldnt change the rotors, Cuz they are pressed on....I told another guy mechanic that says he is able to get them off - Is there a way he can, I dont want to be left witht he same problem then have to go...

- Q: Will doing pushups hinder bench press gains?

- No. While you are focusing on the pecs and secondarily triceps, they also recruit different muscles. For example, if you can bench press 400lbs, that doesn't mean you can do a push-up if you added weight to your back in order to get added weight + your weight to 400lbs. The converse is also true: just because you can push your body up doesn't also mean that you can bench your body weight. The two are separate things. Another factor is that push-ups are typically done in long sets, or at least that's what you end up striving for. Bench press, and most other lifting, is done with reps anywhere from 1-15 per set (depending on your goals). Do both, as they complement each other.

- Q: i use a french press and i get small particles in my coffee that taste bad. what kind of filter can i use to filter those particles out? name a SPECIFIC product that i can buy.

- tshirt, fruit of the loom to be more specific

Send your message to us

High Speed Laminatings Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords