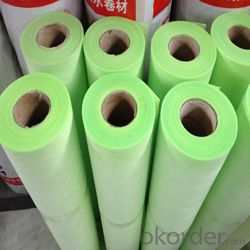

High polymer pp pe pp waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Polymer polyethylene polypropylene composite

waterproof membrane

PP+PE+PP composite waterproof membrane is made by multipleply different materials,

especially its aging and weathering resistance layer enables the membrane possess

more longer effective age. It can bond with many kinds of adhesions, firm and secure.

In case of cement-base, cementations agent can be used, the cementationsagent

can easily enter into the non-woven felt layer, forms a well-combination with cement

after solidification, permanent durability.

1.Specifications:

2.Core Material: PE, EVA

3.Color: black, white, green, grey

4.Weight: 300g/m2-800g/m2

5.Length: 100M, 50M

6.Width: 1.15M, 1.20M, 1M

7.Thickness: 0.6mm-1.5mm

8.Technics: Heat synthesis

9.Payment: T/T

10.Port: Qingdao

11.Origin: CHINA

12.Packaging & Delivery: Packed in roll, will deliver after 7-14 days after receive the prepayment

Characteristic:

1. Non-toxic, no pollution, environmental protecting product.

2. Can be used for many different surfaces, especially for cement basement.

3. Tough, impermeable, multi-layered sheet;

4. High tension strength, good cold flexibility.

Application:

Products used in roofing, basement, restroom, water conservation, warehouse to

protect structure from water infiltration.

Construction:

1.The application is simple and no-pollution. It is mainly used in the middle of building

for waterproofing. On this layers of protection and decoration are needed;

2. When application, pour the adhesive materials homogeneously on the smooth roof

deck, then roll the membrane to make is fully adhered to the deck.

3. The adhesive materials are usually made form cement or other building glue

- Q: Are waterproofing membranes resistant to high-pressure water jets?

- Yes, waterproofing membranes are generally resistant to high-pressure water jets. These membranes are designed to provide a barrier against water penetration and are tested to withstand various water pressures. The level of resistance may vary depending on the specific type and quality of the membrane. However, in general, waterproofing membranes are engineered to withstand high-pressure water jets, ensuring effective protection against water infiltration and potential damage to the underlying structure.

- Q: Can a waterproofing membrane be used on precast glass surfaces?

- Indeed, precast glass surfaces can benefit from the utilization of a waterproofing membrane. It is common for precast glass surfaces to possess joints and seams that allow water to infiltrate. Applying a waterproofing membrane can effectively establish a protective barrier against water penetration. By doing so, the waterproofing membrane acts as a safeguard, preventing moisture from seeping into the joints and causing potential harm to the precast glass. It is crucial to select a waterproofing membrane specifically designed for glass surfaces and to adhere to the manufacturer's guidelines for proper application. Moreover, it is prudent to perform regular maintenance and inspections to ensure that the waterproofing membrane remains effective over time.

- Q: Can a waterproofing membrane be used on tunnels with historical significance?

- Yes, a waterproofing membrane can be used on tunnels with historical significance. The use of a waterproofing membrane is a common method to prevent water infiltration and damage in tunnels, regardless of their historical significance. It is crucial to protect these tunnels from water damage, as moisture can lead to deterioration, structural issues, and even collapse over time. However, when working with tunnels of historical significance, it is important to take additional precautions to preserve their historical integrity. This may involve using a waterproofing membrane that is visually compatible with the tunnel's original materials, ensuring that the installation does not disrupt or damage any historical features, and obtaining the necessary permissions, permits, and approvals from relevant historical preservation authorities. By following these guidelines, it is possible to effectively waterproof tunnels with historical significance while also preserving their historical and cultural value.

- Q: Can a waterproofing membrane be used for modular buildings or container homes?

- Indeed, modular buildings or container homes can benefit from the utilization of a waterproofing membrane. These types of structures pose distinctive obstacles in terms of waterproofing as a result of their modular design and the possibility of water seepage at joints and connections. By employing a waterproofing membrane, these vulnerable areas can be effectively sealed off, preventing any potential leaks or water-related harm. This versatile solution can be administered to the structure's exterior walls, roof, and foundation, delivering a robust and enduring barrier against water. Furthermore, a waterproofing membrane can be tailored to accommodate the specific needs of modular buildings and container homes, guaranteeing utmost defense against water infiltration.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Yes, a waterproofing membrane can be used in crawlspaces or basements. These membranes are specifically designed to prevent water infiltration and are commonly used in these areas to protect against moisture, dampness, and potential water damage. They create a barrier that keeps water out, helping to keep crawlspaces and basements dry and free from water-related issues.

- Q: Can a waterproofing membrane be used for parking garages?

- Yes, a waterproofing membrane can be used for parking garages. Waterproofing membranes are commonly used in construction to prevent water infiltration and damage to structures. Given the potential exposure of parking garages to water from rainfall, snowmelt, or vehicle fluids, using a waterproofing membrane can help protect the structural integrity of the garage and extend its lifespan.

- Q: Can a waterproofing membrane be used for bridge or tunnel waterproofing?

- Yes, a waterproofing membrane can be used for bridge or tunnel waterproofing. Waterproofing membranes are designed to create a barrier against water infiltration and are commonly used in various construction applications, including bridges and tunnels. These membranes are typically made of materials such as bitumen, PVC, or EPDM, which provide excellent resistance to water penetration. Bridge and tunnel structures are exposed to harsh environmental conditions, including water seepage, which can lead to corrosion and structural damage over time. By applying a waterproofing membrane to the surface of the bridge or tunnel, it helps to prevent water from entering the structure, protecting it against deterioration and extending its lifespan. Waterproofing membranes for bridges and tunnels are specifically engineered to withstand heavy traffic loads, weathering, and other environmental factors. They are designed to be durable, flexible, and resistant to cracking, ensuring long-term protection. These membranes are also typically UV resistant, which helps to maintain their integrity even when exposed to sunlight. Furthermore, waterproofing membranes can be installed in various ways, depending on the specific requirements of the bridge or tunnel project. They can be applied as liquid coatings, sprayed or rolled on, or installed as prefabricated sheets. This versatility allows for customization and efficient installation to suit the unique characteristics of each structure. In conclusion, a waterproofing membrane is a viable and effective solution for bridge and tunnel waterproofing. It provides a reliable barrier against water infiltration, protecting the structure from corrosion and deterioration, and extending its lifespan.

- Q: Can a waterproofing membrane be used on tunnels with soundproofing systems?

- Tunnels with soundproofing systems can benefit from the use of a waterproofing membrane. It is common practice to integrate waterproofing membranes with soundproofing systems in tunnels. This is because tunnels are prone to water infiltration, which can cause structural damage and impact the performance of the soundproofing system. By applying a waterproofing membrane, the tunnel can be shielded from water intrusion, ensuring the durability and efficacy of the soundproofing system. Moreover, the waterproofing membrane aids in maintaining a dry and comfortable environment in the tunnel, which is essential for the efficient operation of the soundproofing system. Therefore, combining a waterproofing membrane with a soundproofing system is highly recommended in tunnels to provide both water protection and sound insulation.

- Q: Are there any specific considerations for installing a waterproofing membrane in high-traffic areas?

- Yes, there are several specific considerations when installing a waterproofing membrane in high-traffic areas. Firstly, the durability and strength of the membrane should be a top priority. High-traffic areas are subject to constant wear and tear from foot traffic, heavy equipment, and other activities. Therefore, the membrane should be able to withstand the load and pressure without getting damaged or compromised. Secondly, the slip resistance of the waterproofing membrane is crucial in high-traffic areas to prevent accidents and ensure safety. The surface of the membrane should provide sufficient grip to minimize the risk of slips and falls, especially in wet conditions. Additionally, the installation process should be carefully planned and executed in high-traffic areas. It is essential to minimize disruptions and inconveniences to the people using the area. This may involve scheduling the installation during off-peak hours or implementing temporary alternative pathways to ensure smooth traffic flow. Furthermore, the choice of materials is important in high-traffic areas. The waterproofing membrane should be resistant to chemicals, oils, and other substances that may be commonly found in such areas. This will help to prolong the lifespan of the membrane and maintain its functionality over time. Lastly, regular maintenance and inspection are crucial for long-term performance in high-traffic areas. The membrane should be regularly checked for any signs of damage or deterioration, and necessary repairs or replacements should be promptly carried out to ensure the continued effectiveness of the waterproofing system. In conclusion, installing a waterproofing membrane in high-traffic areas requires careful consideration of durability, slip resistance, installation process, material choice, and maintenance. By addressing these specific considerations, a waterproofing membrane can effectively protect the underlying structure while accommodating the demands of heavy foot traffic.

- Q: How does a waterproofing membrane handle water vapor transmission?

- A waterproofing membrane handles water vapor transmission by preventing the passage of water vapor through its surface. It acts as a barrier to prevent moisture from penetrating the membrane, thus protecting the underlying structure from potential damage caused by moisture.

Send your message to us

High polymer pp pe pp waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords