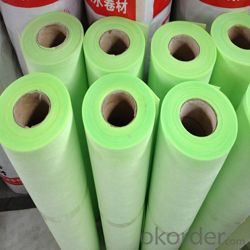

High polymer waterproof membrane PP and PE compound

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Polymer polyethylene polypropylene composite

waterproof membrane

PP+PE+PP composite waterproof membrane is made by multipleply different materials,

especially its aging and weathering resistance layer enables the membrane possess

more longer effective age. It can bond with many kinds of adhesions, firm and secure.

In case of cement-base, cementations agent can be used, the cementationsagent

can easily enter into the non-woven felt layer, forms a well-combination with cement

after solidification, permanent durability.

1.Specifications:

2.Core Material: PE, EVA

3.Color: black, white, green, grey

4.Weight: 300g/m2-800g/m2

5.Length: 100M, 50M

6.Width: 1.15M, 1.20M, 1M

7.Thickness: 0.6mm-1.5mm

8.Technics: Heat synthesis

9.Payment: T/T

10.Port: Qingdao

11.Origin: CHINA

12.Packaging & Delivery: Packed in roll, will deliver after 7-14 days after receive the prepayment

Characteristic:

1. Non-toxic, no pollution, environmental protecting product.

2. Can be used for many different surfaces, especially for cement basement.

3. Tough, impermeable, multi-layered sheet;

4. High tension strength, good cold flexibility.

Application:

Products used in roofing, basement, restroom, water conservation, warehouse to

protect structure from water infiltration.

Construction:

1.The application is simple and no-pollution. It is mainly used in the middle of building

for waterproofing. On this layers of protection and decoration are needed;

2. When application, pour the adhesive materials homogeneously on the smooth roof

deck, then roll the membrane to make is fully adhered to the deck.

3. The adhesive materials are usually made form cement or other building glue

- Q: Are there different waterproofing membrane options for above-ground and below-ground applications?

- Yes, there are different waterproofing membrane options available for above-ground and below-ground applications. Above-ground applications typically involve waterproofing structures such as roofs, balconies, or walls. For these applications, commonly used waterproofing membrane options include liquid-applied membranes, sheet membranes, and polyurethane membranes. These membranes are designed to withstand exposure to weather elements such as UV rays, temperature changes, and foot traffic. On the other hand, below-ground applications involve waterproofing structures like basements, foundations, or tunnels. Below-ground waterproofing membranes are specifically designed to withstand hydrostatic pressure from the surrounding soil and groundwater. These membranes are typically thicker and more durable than above-ground membranes. Commonly used below-ground waterproofing options include bituminous membranes, bentonite clay membranes, and composite membranes. It is important to choose the right waterproofing membrane for each specific application as the requirements and challenges can vary. Consulting with a waterproofing professional or engineer can help determine the most suitable membrane option for both above-ground and below-ground applications.

- Q: Can a waterproofing membrane be used on wood block surfaces?

- Certainly! Waterproofing membranes are a suitable option for safeguarding wood block surfaces. The utilization of a waterproofing membrane on wood block surfaces, like decks or wooden floors, can prove advantageous by shielding against water damage and prolonging the wood's lifespan. These membranes function as a barrier, effectively preventing water from infiltrating the wood and causing deterioration, such as rot, warping, or decay, over time. To guarantee optimal outcomes, it is crucial to select a waterproofing membrane explicitly designed for wood surfaces and adhere to the manufacturer's instructions for application. By doing so, the wood block surface can be adequately protected and maintained, ensuring its resilience and longevity.

- Q: Is a waterproofing membrane breathable?

- No, a waterproofing membrane is not typically breathable. The purpose of a waterproofing membrane is to create a barrier that prevents water or moisture from penetrating through it. In order to achieve this, the membrane is designed to be impermeable to water molecules. However, this lack of permeability also means that air and moisture vapor cannot easily pass through the membrane, resulting in a lack of breathability.

- Q: Can a waterproofing membrane be installed on vertical surfaces without sagging or slumping?

- Yes, a waterproofing membrane can be installed on vertical surfaces without sagging or slumping by using proper installation techniques and selecting a membrane that is specifically designed for vertical applications.

- Q: Can a waterproofing membrane be used for water tanks or reservoirs?

- Yes, a waterproofing membrane can be used for water tanks or reservoirs. The membrane will provide an effective barrier that prevents water from seeping through the tank or reservoir, ensuring its integrity and preventing leaks.

- Q: How does a waterproofing membrane handle movement or settling of a building?

- A building's movement or settling can be accommodated by a waterproofing membrane in several ways. Firstly, the membrane is typically installed in a manner that allows it to stretch or flex as the building moves. This elasticity ensures that the membrane remains intact and continues to provide a watertight seal, even if the structure shifts or settles. In addition, waterproofing membranes often include reinforcement materials, such as fabrics or fibers, which enhance their ability to withstand movement. These reinforcements help distribute the stress or strain caused by building movement across a larger area, reducing the risk of tears or failures in the membrane. Moreover, certain waterproofing membranes are designed with built-in features that can handle significant movement. For instance, some membranes possess special "crack-bridging" properties, enabling them to span small cracks that may develop in the building's substrate due to settling. This ensures that the membrane remains effective, even if the structure sustains minor damage. In cases where a building is expected to experience significant movement or settling, specialized waterproofing systems, such as joint sealants or expansion joints, may be used in conjunction with the membrane. These systems are specifically designed to handle large or dynamic movements, providing additional protection against water infiltration. Overall, careful design and installation of a waterproofing membrane enable it to effectively handle a building's movement or settling. Its elasticity, reinforcement materials, and additional features ensure that it maintains a watertight seal, even when faced with structural shifts or settlement.

- Q: Can waterproofing membranes be used on concrete floors?

- Yes, waterproofing membranes can be used on concrete floors. Waterproofing membranes are commonly used in construction to prevent water penetration and protect the underlying structure. When applied to concrete floors, these membranes create a barrier that prevents water from seeping through and causing damage. Waterproofing membranes can be particularly useful in areas such as basements, bathrooms, and outdoor patios where water exposure is common. They help to maintain the integrity of the concrete floor and protect it from moisture-related issues like cracking, spalling, and mold growth.

- Q: Does a waterproofing membrane require any maintenance?

- Maintenance is indeed required for a waterproofing membrane. Despite its ability to offer lasting defense against water damage, regular maintenance is vital to maintain its effectiveness. This involves checking the membrane for any indications of harm or wear, such as cracks or punctures, and promptly fixing them. Moreover, regularly cleaning the membrane to eliminate dirt, debris, and potential contaminants will assist in preserving its performance. It is advisable to have professionals who specialize in waterproofing systems carry out regular maintenance to guarantee proper upkeep and prevent any potential problems.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- A waterproofing membrane is specifically designed to shield building materials from water damage. Its purpose is to act as a barrier, preventing water from infiltrating the structure and causing harm. Typically, the membrane is applied to areas prone to water intrusion, such as roofs, basements, and foundations. By creating a watertight seal, it effectively stops water from seeping through and harming the building materials. This safeguard is essential in maintaining the structure's integrity and preventing issues like mold growth, rot, and material decay. However, it's crucial to acknowledge that the effectiveness of a waterproofing membrane can vary based on the product's quality and proper installation. Regular maintenance and inspections are also necessary to ensure the membrane remains intact and continues to safeguard against water damage.

- Q: Can a waterproofing membrane be used for dams?

- Yes, a waterproofing membrane can be used for dams. These membranes are designed to prevent water leakage by creating a barrier that is resistant to water penetration. They can be applied to the surface of the dam to ensure its integrity and prevent seepage of water through the structure.

Send your message to us

High polymer waterproof membrane PP and PE compound

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords