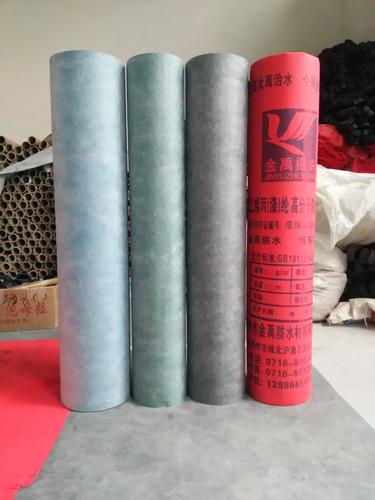

High-polymer Polyethylene Polypropylene Waterproof Membranes

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantages:

The membrane is showed good performance on waterproofness

It will be a high-strength membrane to resist water

Puncture-resisting, tear-resisting, corrosion-resisting, mold-resisting and weather-resisting

Good tensile strength and elongation

Strong adaptability for substrate shrinkage, deformation and cracks

Both high and low-temperature resistance, especially in cold areas

Convenient to apply: use heat fusion method in all seasons

Usage: roof and underground in industrial and civil buildings, bridge, subway, tunnel, swimming pool

Our service:

Provide high-quality and competitive price

Professional sales to answer all your questions about products

Strict quality control of production

Timely communication during the production process

Provide technical support after sales if you needed

- Q: Can a waterproofing membrane be used in areas with high levels of salt or saltwater exposure?

- Yes, a waterproofing membrane can be used in areas with high levels of salt or saltwater exposure. However, it is important to choose a membrane specifically designed to withstand such conditions. Certain waterproofing membranes are specifically formulated to be resistant to salt and saltwater exposure, preventing any potential damage or degradation. These membranes are typically made with materials that are highly resistant to corrosion and have enhanced durability. It is crucial to consult with a professional to ensure the correct type of waterproofing membrane is selected for high salt or saltwater exposure areas to ensure long-term effectiveness and protection.

- Q: How does a waterproofing membrane handle temperature fluctuations?

- A waterproofing membrane is designed to handle temperature fluctuations by being able to expand and contract without compromising its effectiveness. It is made of materials that are flexible and can withstand extreme temperatures, ensuring that it remains intact and continues to provide protection against water infiltration.

- Q: 1.2 thick synthetic polymer waterproofing membrane two weight how to count

- Waterproof to do in what position, the specific requirements, you can contact me, I have a contact in space, the specific use of what materials, synthetic polymer points several categories, the same material is not the same cost

- Q: Can a waterproofing membrane be used on modified bitumen roofs?

- Yes, a waterproofing membrane can be used on modified bitumen roofs. In fact, it is a common practice to enhance the waterproofing capabilities of modified bitumen roofs by applying a separate waterproofing membrane on top. This additional layer provides an extra barrier against water infiltration and helps prolong the lifespan of the roof.

- Q: The difference between waterproof linoleum and waterproofing membrane

- The elastomer (SBS) modified asphalt waterproofing membrane is made of polyester nonwoven fabric or glass fiber mat as the tire base, styrene-butadiene-styrene (SBS) thermoplastic elastomer as modifier, Vinyl film, aluminum foil film, sand, sand, shale made of building waterproof material. The product has a vertical and horizontal tensile strength, good elongation, toughness, low temperature resistance, aging resistance, resistance to ultraviolet light, temperature difference changes, self-healing strength and other excellent performance.

- Q: Are waterproofing membranes suitable for below-grade applications?

- Yes, waterproofing membranes are suitable for below-grade applications. These membranes are specifically designed to prevent water infiltration into basements, foundations, and other below-ground structures. They provide a protective barrier against groundwater, ensuring the integrity and longevity of the structure.

- Q: Can a waterproofing membrane be used for plant rooms and mechanical equipment areas?

- Yes, a waterproofing membrane can be used for plant rooms and mechanical equipment areas. Plant rooms and mechanical equipment areas often require waterproofing to protect the equipment and surrounding structures from water damage. A waterproofing membrane is a commonly used solution for this purpose. It creates a barrier that prevents water from penetrating into the plant rooms and mechanical equipment areas, ensuring that the equipment remains dry and protected. The waterproofing membrane also helps to prevent moisture-related issues such as mold and mildew growth, which can be detrimental to the operation of the equipment and the overall functionality of the plant room. Overall, using a waterproofing membrane in plant rooms and mechanical equipment areas is a reliable and effective way to ensure the longevity and performance of the equipment and structures.

- Q: Can a waterproofing membrane be used for pond or pool applications?

- Certainly! A waterproofing membrane is suitable for both pond and pool applications. Its main purpose is to create a barrier that prevents water from penetrating, making it an excellent choice for sealing ponds and pools. These membranes are typically made from synthetic materials like PVC, EPDM, or TPO, all of which have high resistance to water and UV rays. They come in different thicknesses and can be tailored to fit the specific dimensions of the pond or pool. Moreover, waterproofing membranes are incredibly durable and flexible, allowing them to withstand continuous exposure to water and the movement of the underlying substrate. In summary, utilizing a waterproofing membrane for pond or pool applications helps avoid leaks, extends the lifespan of the structure, and guarantees a safe and enjoyable water environment.

- Q: Can a waterproofing membrane be used for foundation walls?

- Yes, a waterproofing membrane can be used for foundation walls. Waterproofing membranes are commonly used to protect foundation walls from moisture, preventing water penetration and potential damage to the structure. These membranes are designed to create a protective barrier against water, helping to keep the foundation dry and maintaining its structural integrity.

- Q: Can waterproofing membranes be used on concrete block walls?

- Yes, waterproofing membranes can be used on concrete block walls. In fact, it is often recommended to use waterproofing membranes on concrete block walls to prevent water infiltration and moisture damage. Waterproofing membranes are designed to create a barrier against water and can be applied to the exterior or interior surface of the concrete block walls. These membranes provide an additional layer of protection, preventing moisture from seeping into the walls and causing issues such as mold growth, efflorescence, and deterioration of the concrete blocks. By using waterproofing membranes, you can ensure the longevity and durability of your concrete block walls.

Send your message to us

High-polymer Polyethylene Polypropylene Waterproof Membranes

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords