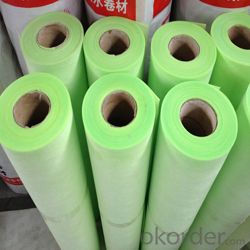

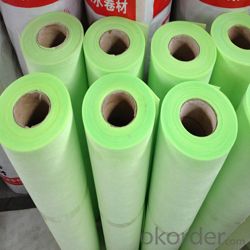

High polymer PP and PE waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Polymer polyethylene polypropylene composite

waterproof membrane

PP+PE+PP composite waterproof membrane is made by multipleply different materials,

especially its aging and weathering resistance layer enables the membrane possess

more longer effective age. It can bond with many kinds of adhesions, firm and secure.

In case of cement-base, cementations agent can be used, the cementationsagent

can easily enter into the non-woven felt layer, forms a well-combination with cement

after solidification, permanent durability.

1.Specifications:

2.Core Material: PE, EVA

3.Color: black, white, green, grey

4.Weight: 300g/m2-800g/m2

5.Length: 100M, 50M

6.Width: 1.15M, 1.20M, 1M

7.Thickness: 0.6mm-1.5mm

8.Technics: Heat synthesis

9.Payment: T/T

10.Port: Qingdao

11.Origin: CHINA

12.Packaging & Delivery: Packed in roll, will deliver after 7-14 days after receive the prepayment

Characteristic:

1. Non-toxic, no pollution, environmental protecting product.

2. Can be used for many different surfaces, especially for cement basement.

3. Tough, impermeable, multi-layered sheet;

4. High tension strength, good cold flexibility.

Application:

Products used in roofing, basement, restroom, water conservation, warehouse to

protect structure from water infiltration.

Construction:

1.The application is simple and no-pollution. It is mainly used in the middle of building

for waterproofing. On this layers of protection and decoration are needed;

2. When application, pour the adhesive materials homogeneously on the smooth roof

deck, then roll the membrane to make is fully adhered to the deck.

3. The adhesive materials are usually made form cement or other building glue

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Yes, a waterproofing membrane can be used for theaters or concert halls. Waterproofing membranes are commonly used in construction to protect buildings from water damage. The membrane can be applied to various surfaces, including walls, floors, and roofs, helping to prevent water penetration and moisture-related issues. In theaters or concert halls, where there may be a significant risk of water damage due to heavy rain, leaks, or potential spills, using a waterproofing membrane can provide an extra layer of protection and help preserve the structural integrity of the building.

- Q: Are waterproofing membranes resistant to chemicals?

- Waterproofing membranes are generally resistant to chemicals, providing a protective barrier against water infiltration. These membranes are typically made from materials like PVC, TPO, or EPDM, which possess excellent chemical resistance properties. Their engineering ensures they can endure exposure to various chemicals like acids, alkalis, solvents, and oils without deteriorating. This chemical resistance guarantees that waterproofing membranes can maintain their integrity and effectiveness even in environments with common chemical exposure, such as industrial settings, laboratories, or chemical storage areas. However, it is important to consider that the specific chemical resistance capabilities may differ based on the type and quality of the chosen waterproofing membrane. Therefore, it is crucial to select the appropriate membrane that matches the project's specific chemical exposure requirements.

- Q: Can a waterproofing membrane be used for a parking garage deck?

- Indeed, a parking garage deck can benefit from the use of a waterproofing membrane. Its purpose is to safeguard the underlying structure by creating a barrier against water infiltration. Given the exposure of parking garage decks to various weather conditions and potential vehicle-related leaks, it is imperative to employ a waterproofing membrane to shield the concrete slab and prevent moisture-related problems such as cracking, corrosion, and deterioration. By implementing a waterproofing membrane on the parking garage deck, a protective layer is established, effectively blocking water from permeating the concrete. This membrane can be applied in the form of a liquid coating, sheet membrane, or a combination thereof. The selection of the appropriate membrane depends on factors including the desired level of protection, traffic load, and project-specific requirements. Moreover, a waterproofing membrane for a parking garage deck offers additional advantageous properties aside from water resistance. Some membranes are engineered to withstand chemicals and oil, which is vital considering the potential exposure to vehicles. Additionally, they provide an extra layer of defense against freeze-thaw cycles that may inflict harm upon the concrete structure. It is crucial to note that the installation of a waterproofing membrane for a parking garage deck should be carried out by experienced professionals who adhere to the manufacturer's guidelines and industry standards. Proper surface preparation, including thorough cleaning and repair of any cracks or defects, is imperative to ensure the long-term effectiveness of the membrane. In conclusion, a waterproofing membrane proves to be an effective solution for safeguarding a parking garage deck against water damage. It serves to prevent water infiltration, safeguard the concrete from deterioration, and enhance the overall durability and lifespan of the structure.

- Q: Can a waterproofing membrane be used on tunnels?

- Yes, a waterproofing membrane can be used on tunnels. Waterproofing membranes are commonly used in tunnel construction to prevent the ingress of water and protect the structure from potential water damage. These membranes are designed to be highly durable, flexible, and resistant to external factors such as water pressure and ground movements. They provide a reliable barrier against water infiltration, helping to maintain the structural integrity of the tunnel and ensure its long-term functionality.

- Q: Can a waterproofing membrane be used for below-grade parking structures?

- Yes, a waterproofing membrane can be used for below-grade parking structures. These membranes are designed to provide a barrier against water intrusion and can be applied to the below-grade walls and floors of parking structures to prevent water damage and leakage.

- Q: How does a waterproofing membrane handle exposure to high temperatures?

- The ability of a waterproofing membrane to withstand high temperatures relies on its composition and quality. These membranes are typically made from durable materials like bitumen, EPDM, or PVC, which have high melting points and can resist heat. These materials are carefully selected to ensure that the membrane remains intact and effective even when exposed to elevated temperatures. The resistance of high-quality waterproofing membranes to heat is enhanced through the use of additives and fillers during manufacturing. These additives help the membrane maintain its integrity, preventing it from softening, melting, or becoming brittle under high temperature conditions. Additionally, the successful installation of the waterproofing membrane is crucial to its ability to handle high temperatures. Proper installation techniques, such as ensuring adequate adhesion and seam sealing, are essential for maintaining the membrane's effectiveness and preventing any potential damage caused by heat exposure. To summarize, waterproofing membranes are specifically engineered to withstand high temperatures. Their composition, quality, and installation techniques all contribute to their ability to resist heat without deteriorating or losing their waterproofing properties.

- Q: Can a waterproofing membrane be used for restaurants or kitchens?

- Restaurants or kitchens can indeed utilize waterproofing membranes. These membranes are frequently employed in these spaces to safeguard the foundational structure against water damage. Generally, they are installed in areas prone to water exposure such as floors, walls, and countertops. By preventing water infiltration into the building materials, waterproofing membranes avert deterioration, mold growth, and other related problems. Furthermore, these membranes are specifically designed to resist chemicals and stains commonly found in restaurant or kitchen settings. In conclusion, the use of a waterproofing membrane is an effective means to ensure the durability and longevity of the restaurant or kitchen, while also upholding a sanitary and hygienic environment.

- Q: Can a waterproofing membrane be used for solar panel installations?

- Yes, a waterproofing membrane can be used for solar panel installations. Waterproofing membranes are commonly used in construction to create a watertight barrier. When properly installed, they can effectively protect the underlying structure and prevent water leakage. This makes them a suitable option for protecting solar panel installations from potential water damage.

- Q: Can a waterproofing membrane be used for a water tank sealant?

- Yes, a waterproofing membrane can be used as a water tank sealant. Waterproofing membranes are designed to prevent the passage of water and are commonly used to seal various structures, including water tanks. They provide a durable and effective barrier against water infiltration, protecting the tank from leaks and potential damage. However, it is important to ensure that the waterproofing membrane used is specifically designed for water tanks and meets the necessary standards and regulations for the specific application. It is also recommended to consult with a professional or a reputable manufacturer to ensure the correct product and installation method are used for optimum performance and longevity.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Yes, a waterproofing membrane can be used for plant rooms or mechanical spaces. These areas often require protection against water damage due to the presence of pipes, equipment, or other mechanical systems. A waterproofing membrane provides an effective barrier to prevent water intrusion and protect the integrity of the space.

Send your message to us

High polymer PP and PE waterproof membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords