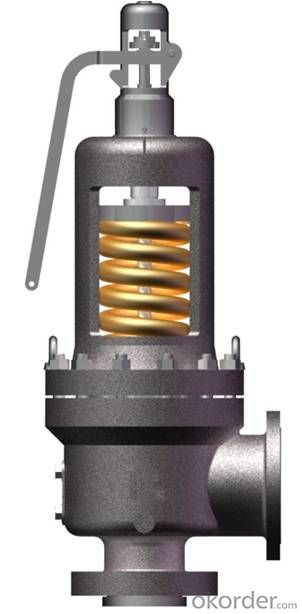

High Performance WCB Safety Valve For Steam Service

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

A pressure relief valve (PRV) is a safety device that relieves overpressure in a vessel or system. When the pressure of vessel or system increased beyond the specified design pressure or maximum allowable working pressure, PRV will be opened automaticly to relief the overpressure for proteding the vessel or system. The PRV will be closed if the pressure reached specified design pressure so that to ensure the normal operation and protect the vessel or system.

Our Pressure Relief Valve has been designed and manuractured according to following Standard:

♦ ISO 4123-1 Safety Devices for Portection Against Excessve Pressure

♦ API STD 526 Flanged Steel Pressure Relief Valves

♦ API STD 527 Seat Tightness of Pressure Relief Valves

♦ ASME Boiler and Pressure Vessel Code Section VIII Division 1, Rules for Construction of Pressure Vessels

Peformance:

♦ Type: Conventional, Bellows

♦ Size:1" D 2"- 8" T 10"

♦ Class:150lb~2500lb

♦ Temperature:-268~+538°C

♦ Fluid: Gas, Steam, and Liquid

♦ Material: Carbon steel, Stainless steel, Alloy steel

♦ The allowable tolerance of the set pressure: ≤±3%

♦ Overpressure: ≤10%(gas)/≤20%(liquid)

♦ Blowdown: ≤10%(gas)/≤20%(liquid)

♦ Tightness: conforms to API STD 527

Features:

♦The solid nozzle is screwed into the body, which makes the maintenance easy.

♦ The shape of the disc holder has been designed to enhance the effect of the fluid thrust for an instant lift of the disc.

♦ Blowdown control is provided with adjustable nuzzle ring only.

♦ The adequate terials and clearance between disc holder and guide , spindle and adjusting screw assures disc to lift successfully.

♦ The surface of both the disc and the nozzle seat are deposited with Stellite. Excellent flatness and surface finish of the seating surfaces by precision machining and lapping assure pressure relief valve to have high degree of seat tightness and long using life.

♦ The bellows of balanced bellows pressure relief valves can not only avoid and effect of variable back pressure in the system , but also protect spring and other trim components from corrosive media.

♦ Materials are chosen carefully , and the manufacture of the spring and the bellows has strict technological process. Each of them is tested and checked strictly.

- Q: can you spray WD-40 on it so you can turn it off?

- this is something to try, but if it doesn't work, you are going to need to call in a pro for help.

- Q: I have a no start on a briggs and straon 16.5 OHV. It has spark, and fuel. and backfire's through the intake. I took off the top of the motor to check the key way and it was in place. I think its a valve timing issue but what times the valve? I have not removed the flywheel yet because i need a puller. Is there another key way under the flywheel that times the valves

- you can,t tell if the key way is sheared by looking at the flywheel it has to be pulled, did you hit something when mowing? good indication that the key is sheared, the valves run off a cam like in a car if not then you have a burnt valve

- Q: Okay so my boyfriend's father is getting a heart valve replacement....he's so nervous he cried last night when he heard it will be in 2 weeks....and he's usually one of those tough guys has anyone or know anyone who has had this type of surgery. They are leaning towards a animal (cow or pig) valve...because with mechanical you have to take blood thinners for the rest of your life...anyways if anyone knows information on this or knows the pro's and cons of the two diff. types of valves please give me info. Thanks

- I worked in ICU for 16 years, 8 of them with open heart patients. My dad also had 3 bypasses and 2 valves replaced at age 80. He will celebrate his 89th birthday in May. My dad had the mechanical because being 80, it should last the rest of his life. He does take blood thinners, as do millions of other people in the world. It's really not that big a deal, and if it prevents strokes and other problems related to clots, people accept that. You got a lot of good information in the Answer before mine, so I won't repeat. Just understand that it's perfectly normal to be petrified and tearful and scared about such a major surgery. Even the big macho men feel that way, and many of them had fears long after they had the valve done. It's normal. Attitude is a very big factor in uneventful recovery, those with more positive attitudes got better more quickly. So after the initial shock wears off, be sure that all of you encourage him, listen to his fears but help him understand it's a new lease on life for him and that all of you will be there to help him get back on his feet as quickly as possible. When I first started nursing, people would be in ICU for 4-5 days, then in the hospital another 2 weeks after having heart surgery. My dad was home in 5 days, and that was 9 years ago! Heart surgery has come a long way, and he has every right to be hopeful about the outcome. Good luck to him and all of you!

- Q: I recently converted my furnace from l.p. gas to natural gas. It's been maybe two weeks of me troubleshooting and replacing. I have a new gas valve and transformer in the furnace. There is 24v running to the valve and it clicks to open but no gas comes out. I have exhausted all my options with the mechanical/electrical components on the furnace. I have bled the valve to be sure that there was gas making it to the inlet side. Does anyone have an idea as to why the valve stopped opening once I converted it over?

- I realize this is probably a dumb question, but it has to be asked, just so everyone else won't have to wonder. Are you dead sure you put the valve on in the right direction? I'm not a certified furnace installer or repair person, so I don't actually know if it's even possible to put a valve on backwards, so, the question. It certainly sounds like you've done everything that could be done, other than to take the valve off and try getting it to open while it's off. If it's opening, it should do it on a bench, with 24 volts going to it. You may have to take the transformer with it to be sure, and actually look up in the holes to see if you can spot the flap opening up for the gas to flow. You haven't mentioned a pilot at all, so I have to wonder if this is an igniter type system? That would be my methodology of checking the valve and the transformer. If you can get it to open on the bench, then it certainly should open in place.

- Q: The hot water shutoff valve to the washing machine was dripping. I removed the packing nut and put in new packing over the weekend. Problem is that the packing nut seems to only go back on at an angle no matter what I do...it may have already been that way though. The valve isn't currently dripping, but I'm not liking the way the packing nut only goes on at an angle. Would it be crazy to keep the existing valve if I keep an eye on it and over time it doesn't drip, or is it too risky to keep this valve given that the packing nut is on at a funny angle? (Local plumbers here in Northern NJ all want around $350 if I were to replace both the hot and cold with a watts single handle valve.) Thanks, J.

- An old saying I like is If it ain't broke, don't fix it!. Even though the packing nut appears to be cross-threaded, if there is no leak, I'd leave it alone. Washer connection stop valves seldom get used. They mostly just stay on, unless you have a washing machine breakdown. I'd just peek at it each washday. If it doesn't leak, I'd leave it be.

- Q: How do you repack an osy valve? Where do you get the packing from? Do you have to shut down the water to do it?

- where is i get the packing gland material

- Q: I have a 04 Ford Ranger 4.0L . some people are saying that headers may affect the EGR valves and might put up the check engine light on. is this true or not.

- the okorder so the headers stay tight and wont leak..

- Q: hi can any one help me ajust the valves on my 1981 xs650 witch side do i start on and any help will be great i was told it is not hard i an 72 years old and i do all my own tune ups but i forget thanks pop.

- Remove both spark plugs. Remove all 4 valve inspection covers. Remove the Generator cover (L crankcase cover, round, 2 screws). It doesn't matter which side you start on. Turn the crankshaft in the direction the engine runs. Depending on which cylinder you're working on, watch that intake valve. When the rocker arm pushes it down, then comes back up, the piston is then moving up on the compression stroke. Continue turning until the piston is at top dead center. You can line up the T mark on the flywheel with the pointer, or look into the spark plug hole to see when the piston is at the top. Adjust the valve clearance for the intake exhaust valves on that cylinder. Repeat for the 2nd cylinder.

- Q: Defects in which valves would produce the following?1) SEVERE DEPENDENT EDEMA?2) PAROXYSMAL NOCTURNAL DYSPEA3) CONGESTED LIVER?4) DISTENDED JUGULAR VEINS?5) PRODUCTIVE COUGH WITH FROTHY SPUTUMfor 1. i believe it's tricupsid valve, 2. mitra valve please correct me if I'm wrong. Thaanks!

- Tricuspid regurgitation: Symptoms of right-sided heart failure, such as ascites, hepatomegaly, edema and jugular venous distension.

- Q: I was diagnosed with Mitral Valve Prolapse. Does anyone else have this? Does this cause panic attacks? I have heard that. What other problems does it cause?

- What is mitral valve prolapse? How does a patient with MVP feel? How is mitral valve prolapse diagnosed and evaluated? What is the treatment for MVP? Mitral Valve Prolapse At A Glance What is mitral valve prolapse? Mitral valve prolapse (also known as click murmur syndrome and Barlow's syndrome) is the most common heart valve abnormality, affecting five to ten percent of the world population. A normal mitral valve consists of two thin leaflets, located between the left atrium and the left ventricle of the heart. Mitral valve leaflets, shaped like parachutes, are attached to the inner wall of the left ventricle by a series of strings called chordae. When the ventricles contract, the mitral valve leaflets close snugly, preventing backflow of blood from the left ventricle into the left atrium. When the ventricles relax, the valves open to allow oxygenated blood from the lungs to fill the left ventricle. In patients with mitral valve prolapse, the mitral apparatus (valve leaflets and chordae) becomes affected by a process called myxomatous degeneration. In myxomatous degeneration, the structural protein, collagen, forms abnormally and causes thickening, enlargement and redundancy of the leaflets and chordae. When the ventricles contract, the redundant leaflets prolapse (flop backwards) into the left atrium, sometimes allowing leakage of blood through the valve opening (mitral regurgitation). When severe, mitral regurgitation can lead to heart failure and abnormal heart rhythms. Most patients are totally unaware of the prolapsing of the mitral valve. Others may experience a number of symptoms discussed below. The mitral valve prolapse (MVP) syndrome has a strong hereditary tendency, although the exact cause is unknown. Affected family members are often tall, thin, with long arms and fingers, and straight backs. It is seen most commonly in women from 20 to 40 years old, but also occurs in men.

Send your message to us

High Performance WCB Safety Valve For Steam Service

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords