High Performance Safety Valve For Steam Service

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

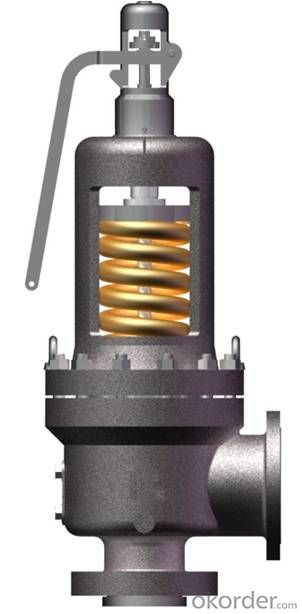

High Performance Safety Valve For Steam Service1. High Performance

2. Competitive Price

3. Prompt Delivery.

High Performance Safety Valve For Steam Service

Product Information:

Manufactured according to ASME SECTION I

Size: 1 1/2" -- 6"

Pressure: 300LB -- 2500LB

Temperature: ±520°c

Product Feature:

The back pressure adjusting system utilizes the flowing steam to build and adjust back pressure, to ensure that lowdown is not more than 4% of set pressure.

Nozzle is welded with body, to make connection stable when it's serviced in the condition of high temperature and high pressure.

Connection of inlet and outlet is flange type, to make installation and maintenance easy.

Perfect guide design provides well alignment, to ensure that the operation of valve is agile and stable.

The selected materials are of high performance, which can be used in high temperature condition.

The nozzle and disc is faced with satellite, and lapped precisely.

Spring is produced through excellent technology, and tested under simulative service condition.

- Q: whats the location of the pcv valve on on a 2001 bmw 740il (e38)

- In front of the engine slightly to the left and lower area of the throttle valve. It is a round black plastic canister supported by a teardrop shaped rubber with a cable connector at the top and 2 hose connections at the opposite end of the cable connector which are perpendicular to each other. BMW calls it the tank vent valve.

- Q: what is the reason for a 30 degree angle valve cut ? should i have this done on a Street performer 351 windsor with stock street heads and a mild cam?

- Makes the intake and exhaust flow smoother.

- Q: I just installed three anti-siphon valves(jar top,orbit) for a sprinkler system the main water line is 3/4 then goes into my manifold (pvc)3/4 schedule 40,usually when you turn on the water it comes to a stop where you re valves begin then you either open them manually or their set up through you re timer, the problem im having when i open the main water line the water goes straight through the valves without me even opening them my question is can it be to much pressure or what can the problem be? any info helps thank you

- possibly they can give some insight on your problem.

- Q: Hey,Recently purchased a 2006 Audi A4 2.0T Q S-Line. Loving it so far but i can barley hear the blowoff valve if at all. So i am in the market for the loudest blowoff valve. I realize its a very tiny turbo but id still like to hear it and maybe even turn some heads. If anyone can help me out i would greatly appreciate it. Thank you

- first off dude, it comes stock with a diverter valve. ive been doing research and so far the best thing ive found to get it loud is to upgrade the diverter valve and get a spacer (all forge) if you dont wanna spend that much then idk what to tell you. chipping your car improves boost so that would help too, also a cold air intake could improve it. all together and youll turn some heads. i have the same car just not s-line mines quartz grey :) good luck bro rick from philly

- Q: is it possible to check valve to piston clearance with out taking the heads off? I want to buy a bigger camshaft for my 351 windsor stock pistons with 1970 heads. cam is 230 duration (280) and 512 lift

- No you can't check the valve to piston clearance without taking the heads off. I had a 289 bored out to 351 and ran stock 351 pistons. So your stock pistons should work with the new camshaft. I know I'm a girl but my husbands a mechanic and for fun we rebuild muscle cars.

- Q: I have 06 Suzuki gsx-r 750 and i was wondering what are the signs or how do i know that my valves need to be adjusted?

- The only way is to pull the cam covers and check them with a feeler gauge.This should be done at least once a year as part of your regular maintenance.

- Q: Exactly what is an EGR valve where is it located?

- In todays engines , fuel economy is a big issue. An exhaust Gas valve will do the following. At cruise speed, when there is not as much load on the engine the fuel mixture will lean out to save on fuel emissions, but the combustion temp will rise with a lean mix, so to control this the egr valve will throttle exhaust gas into the intake air leaning out the air and lowering the combustion temp. exhaust gas will not burn again! its burnt already, mechanical valves were easy to check with a vacum pump. but newer valves are controled by the engine control system and you should consult your service manual for proper inspection procedures

- Q: 1994 Chevy K1500 P/U 5.7 liter 350 4X4 5 speed. When the truck is under a hard pull the valves start knocking, the knock sensor adjust the timing and the check engine light comes on. The code for the light is not detecting knock sensor. I have changed the pcv valve (which was suggested) and no change. This has went on for about 5 years. Doesn't matter the grade of fuel I use. Routine maintance and tune ups have been done to this truck. The converter was taken off 7 years ago because it was clogged. The truck runs rich after the timing adjust. The light resets itself when it is turned off. ( the code is saved)

- disconnect the positive battery terminal for a couple minutes. Other than taking it in to have it reset that is the most generic way to clear it. but it sounds like your timing advance system is not working.

- Q: my mid eighties GM full size car with a 305 just started to have a problem...it runs fine at idle.....runs rough/sluggish at speed......when I take my foot off the gas there is a fast rattle in the engine.........and sometimes the engine likes to idle fast.....I replaced the catalytic converter last year ...........so now I am thinking of changing the egr valve....there is no service engine soon light on and this car is a mid eighties so no obd 2 system on this car......any other ideas? thanks

- EGR valve got sooty,and rusty and dirty and then they dont work right. They either dont open or they get stuck open and cause the car to run lousey. If the valve has been i the car since the 80's it is probably about time to either clean it or change it. do you have haynes or chilton manual for the car? they explain alot.

- Q: what is the purpose of valves such as: gate valve, foot valve and globe valve in the industry?

- the valves control the flow

Send your message to us

High Performance Safety Valve For Steam Service

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords