Monolithic Refractories for Iron and Steel Industry - High Alumina Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of High Alumina Based Mortar for Hot Blast Stove

FIREF high alumina mortar for hot blast stove made as per international standards, is known for its low thermal conductivity, high refractoriness, and excellent thermal shock resistance.

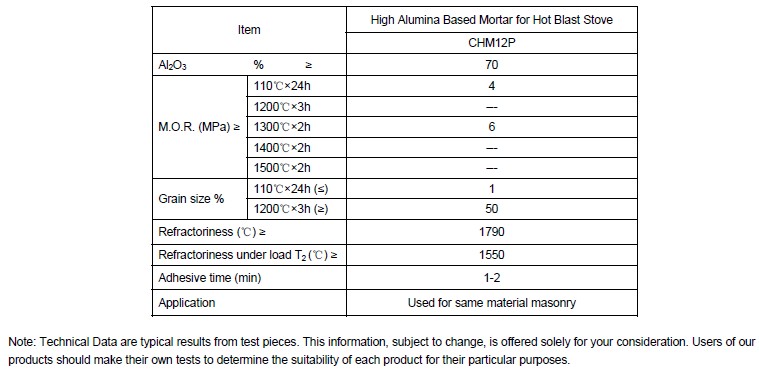

Technical data of High Alumina Based Mortar for Hot Blast Stove

Production line and packing of High Alumina Based Mortar for Hot Blast Stove

Feature of High Alumina Based Mortar for Hot Blast Stove

High refractoriness

Low thermal conductivity

Excellent mechanical strength

Excellent thermal shock resistance

Application of High Alumina Based Mortar for Hot Blast Stove

FIREF high alumina mortar for hot blast stove can be used with the refractory brics of the alike material.

- Q: How are monolithic refractories applied in the hot face and cold face of furnace linings?

- Monolithic refractories are commonly used in furnace linings because of their superior thermal and mechanical properties. These materials are applied in both the hot face and cold face of furnace linings, but the application process differs for each. In the hot face of furnace linings, monolithic refractories are applied to withstand the extreme temperatures and harsh conditions. This is the area that directly faces the heat source and is exposed to the highest temperatures. Here, the refractory material is specifically designed to have excellent thermal conductivity and high resistance to thermal shock. To apply monolithic refractories in the hot face, a technique called gunning is commonly used. Gunning involves spraying or troweling the refractory material onto the surface of the lining. This technique allows for quick and efficient application, ensuring a uniform and dense layer of refractory material. Gunning is particularly suitable for areas with complex shapes and contours. On the other hand, in the cold face of furnace linings, the primary concern is insulation and protection. The cold face is the area that is not in direct contact with the heat source and experiences lower temperatures. Here, the refractory material is designed to have low thermal conductivity and high insulation properties. The application of monolithic refractories in the cold face is typically done using a technique called ramming. Ramming involves compacting the refractory material into place using a pneumatic or hydraulic ramming tool. This technique ensures a dense and solid layer of refractory material, providing excellent insulation and protection against heat loss. Overall, monolithic refractories play a crucial role in furnace linings, as they provide the necessary thermal insulation and mechanical strength required in high-temperature environments. The application techniques of gunning and ramming allow for efficient and effective installation in both the hot face and cold face of furnace linings.

- Q: How do monolithic refractories withstand high temperatures and thermal cycling?

- Monolithic refractories, with their unique composition and structural characteristics, are designed to endure high temperatures and thermal cycling. To begin with, these refractories are composed of high-quality raw materials like alumina, silica, and magnesia. These materials possess exceptional thermal properties, including high melting points and low thermal conductivity. Consequently, they can maintain their strength and integrity even in extreme temperatures. Additionally, monolithic refractories are engineered to have a dense and compact microstructure. This dense structure prevents the infiltration of heat and gases, minimizing thermal shock and crack formation. Moreover, the compact microstructure enhances the refractory's thermal conductivity, allowing it to efficiently distribute and dissipate heat. Furthermore, special additives and bonding agents are often incorporated into monolithic refractories to enhance their resistance to thermal cycling. These additives improve the refractory's thermal expansion properties, enabling it to expand and contract without cracking or spalling during rapid temperature changes. Some bonding agents also provide flexibility to the refractory, allowing it to withstand thermal stresses without compromising its structural integrity. In addition to these inherent characteristics, proper installation techniques are crucial for the refractory's ability to withstand high temperatures and thermal cycling. Careful application and curing ensure uniformity and minimize the development of internal stresses. Adequate curing and heat treatment processes create a strong and durable bond between the refractory and the substrate, enhancing its resistance to thermal shock and cyclic thermal loading. In summary, the composition, microstructure, and installation techniques of monolithic refractories work together to enable them to withstand high temperatures and thermal cycling. These factors result in excellent thermal conductivity, resistance to thermal shock, and the ability to expand and contract without compromising the refractory's structural integrity.

- Q: How do monolithic refractories withstand the corrosive environments in steelmaking processes?

- Due to their unique properties and composition, monolithic refractories are capable of enduring corrosive conditions in steelmaking processes. The primary feature of monolithic refractories is their exceptional ability to withstand high temperatures and thermal shock. Steelmaking procedures involve extremely high temperatures, which can reach up to 1700 degrees Celsius. Monolithic refractories are specifically engineered to endure these extreme temperatures without compromising their structural integrity. Moreover, monolithic refractories exhibit outstanding chemical resistance. The corrosive environments in steelmaking processes often include aggressive chemicals like molten metal, slag, and gases such as carbon monoxide and sulfur dioxide. Monolithic refractories are manufactured using materials that possess resistance to these chemicals. Consequently, these materials prevent any reactions and consequent corrosion. Furthermore, monolithic refractories possess a compact and uniform structure. This characteristic aids in preventing the infiltration of corrosive agents into the refractory material, further augmenting its resistance to corrosion. The compact structure also minimizes the formation of cracks and fissures, which can serve as pathways for corrosive agents to penetrate the refractory. Additionally, monolithic refractories are frequently composed of materials with high refractoriness, such as alumina, magnesia, and silica. These materials possess high melting points, rendering them more resistant to the extreme temperatures encountered in steelmaking processes. They also possess low thermal conductivity, which assists in reducing heat transfer and lowering the risk of thermal damage to the refractory. Lastly, monolithic refractories are often formulated with specific additives and binders that enhance their resistance to corrosion. These additives may include materials like zircon, chrome, or graphite, which provide supplementary protection against the corrosive environment. In conclusion, monolithic refractories demonstrate their ability to withstand the corrosive environments in steelmaking processes through their high resistance to temperature and thermal shock, excellent chemical resistance, dense and uniform structure, high refractoriness, and the utilization of specialized additives and binders. These attributes make monolithic refractories an optimal choice for enduring the rigorous conditions of steelmaking processes, ensuring the durability and efficiency of the refractory lining.

- Q: How do monolithic refractories help in reducing energy consumption in iron and steel production?

- Monolithic refractories play a crucial role in reducing energy consumption in iron and steel production. These refractories are a type of heat-resistant material that is used to line the walls and floors of furnaces and other high-temperature equipment. One of the primary ways monolithic refractories help in reducing energy consumption is through their excellent thermal insulation properties. These materials have low thermal conductivity, which means they can effectively reduce heat loss from the furnace or equipment. By minimizing heat loss, monolithic refractories help maintain a high and consistent temperature inside the furnace, resulting in improved energy efficiency. This allows for better utilization of the heat generated, reducing the need for additional energy input and ultimately leading to energy savings. Moreover, monolithic refractories have high thermal stability and resistance to thermal shock. This means they can withstand the extreme temperatures and rapid temperature changes commonly encountered in iron and steel production processes. By having a durable and reliable lining, these refractories help prevent heat leakage and ensure that the heat is efficiently transferred to the desired areas, reducing energy wastage. Additionally, monolithic refractories also contribute to energy reduction through their ability to resist chemical attack and erosion. In iron and steel production, the lining of furnaces and equipment is exposed to various aggressive substances, such as molten metal, slag, and gases. Monolithic refractories have excellent resistance to these corrosive elements, extending their lifespan and reducing the need for frequent repairs or replacements. This not only saves energy that would be required for maintenance but also avoids production interruptions and associated energy losses. In summary, monolithic refractories assist in reducing energy consumption in iron and steel production by providing effective thermal insulation, withstanding extreme temperatures, and resisting chemical attack. By optimizing heat management and extending equipment durability, these refractories significantly contribute to energy efficiency and cost savings in the industry.

- Q: What is the role of monolithic refractories in blast furnaces?

- Monolithic refractories play a crucial role in blast furnaces as they provide high temperature resistance, erosion and corrosion resistance, thermal insulation, and structural integrity. These refractories are used to line the inside of the blast furnace, forming a protective barrier against the extreme heat and chemical reactions occurring within. They help to maintain the integrity of the furnace and ensure its efficient operation by withstanding the aggressive conditions of the molten iron and slag. Additionally, monolithic refractories allow for easier installation and repair compared to traditional brick refractories, making them a preferred choice in blast furnace applications.

- Q: How do monolithic refractories prevent thermal radiation in the iron and steel industry?

- Monolithic refractories play a crucial role in preventing thermal radiation in the iron and steel industry. Thermal radiation refers to the transfer of heat energy through electromagnetic waves, and it can be a significant challenge in this industry due to the high temperatures involved. Monolithic refractories, which are single-piece refractory materials, are designed to have excellent thermal insulation properties. They have low thermal conductivity, which means they are not good conductors of heat. This property allows them to act as a barrier against thermal radiation. When used in the iron and steel industry, monolithic refractories are typically applied as linings in furnaces, ladles, and other equipment that are exposed to extremely high temperatures. These linings serve as a protective layer, preventing the heat from escaping and reducing the amount of thermal radiation emitted. Additionally, monolithic refractories have high emissivity, which refers to their ability to absorb and re-emit thermal radiation. This property allows them to effectively capture and contain the heat within the equipment, minimizing the amount of radiation that escapes into the surroundings. By preventing thermal radiation, monolithic refractories help to maintain the desired temperatures within the iron and steel production process. This is crucial for achieving efficient and controlled operations, as well as ensuring the quality of the final products. Furthermore, the use of monolithic refractories in the iron and steel industry also contributes to energy savings. By reducing the heat loss through thermal radiation, less energy is required to maintain the desired temperatures, resulting in lower energy consumption and cost savings. In conclusion, monolithic refractories are essential in preventing thermal radiation in the iron and steel industry. Their excellent thermal insulation properties, low thermal conductivity, and high emissivity make them effective barriers against heat transfer through radiation. By minimizing heat loss and ensuring controlled temperatures, monolithic refractories contribute to efficient operations, high-quality products, and energy savings.

- Q: Can monolithic refractories be used for lining iron and steel ladles during casting and pouring?

- Yes, when it comes to lining iron and steel ladles during casting and pouring, monolithic refractories are the go-to option. Unlike traditional refractory bricks, which consist of multiple pieces, monolithic refractories are composed of a single, uniform structure. Monolithic refractories are highly favored for ladle lining in iron and steel casting due to their numerous advantages. Firstly, they exhibit exceptional resistance to thermal shock, enabling them to endure the intense temperatures encountered during casting and pouring. This is of utmost importance since ladles are constantly exposed to extreme heat. Moreover, monolithic refractories provide superior resistance to erosion and corrosion, ensuring that the lining remains intact amidst the harsh conditions and chemical reactions that transpire when molten metal makes contact with the ladle. Additionally, they possess excellent thermal insulation properties, diminishing heat loss and enhancing energy efficiency throughout the casting process. Furthermore, monolithic refractories boast remarkable versatility, enabling easy installation, repair, and replacement. They can be molded and shaped to conform to the specific requirements of ladles, resulting in a snug and secure lining. This adaptability also enables swift maintenance and repair, minimizing downtime and optimizing productivity. In conclusion, monolithic refractories are the perfect choice for lining iron and steel ladles during casting and pouring. Their resistance to thermal shock, erosion and corrosion, thermal insulation properties, and ease of installation render them highly suitable for this demanding application.

- Q: What are the advantages of using monolithic refractories in electric arc furnaces?

- There are several advantages to using monolithic refractories in electric arc furnaces. Firstly, monolithic refractories offer excellent thermal shock resistance. Electric arc furnaces operate at extremely high temperatures, and the refractory lining is constantly exposed to rapid temperature changes. Monolithic refractories are able to withstand this thermal cycling without cracking or deteriorating, ensuring the longevity and efficiency of the furnace. Secondly, monolithic refractories have superior corrosion resistance. Electric arc furnaces often use aggressive slag compositions, which can corrode and erode traditional brick linings. Monolithic refractories, on the other hand, are specifically designed to resist chemical attack, providing long-lasting protection against the corrosive effects of molten metal and slag. Additionally, monolithic refractories offer great flexibility in terms of installation. Unlike brick linings, which require extensive labor and time to construct, monolithic refractories can be easily applied as a liquid or paste, allowing for faster and more efficient installation. This not only reduces downtime during furnace maintenance or repairs but also provides the opportunity for customized linings to be easily created to suit specific furnace designs. Moreover, monolithic refractories have excellent thermal conductivity. This property allows for efficient heat transfer within the electric arc furnace, ensuring optimal energy use and minimizing heat losses. This improved thermal efficiency results in reduced operating costs and increased productivity. Furthermore, monolithic refractories have a high refractoriness, meaning they can withstand extremely high temperatures without deformation or failure. This is crucial for electric arc furnaces, which operate at temperatures exceeding 3000°C. The ability of monolithic refractories to maintain their structural integrity at such extreme temperatures ensures the safe and efficient operation of the furnace. In conclusion, the advantages of using monolithic refractories in electric arc furnaces include their thermal shock resistance, corrosion resistance, ease of installation, high thermal conductivity, and exceptional refractoriness. These properties contribute to improved furnace performance, increased productivity, reduced operating costs, and extended furnace life.

- Q: What are the typical applications of monolithic refractories in blast furnaces?

- Monolithic refractories are widely used in blast furnaces due to their unique properties and applications. These refractories are composed of a single, homogeneous material that can be shaped and installed in various forms without the need for joints or seams. This characteristic makes them ideal for lining and protecting the different zones of a blast furnace. One typical application of monolithic refractories in blast furnaces is the lining of the hearth. The hearth is the bottom part of the furnace where molten iron and slag accumulate. Monolithic refractories are used to create a durable and heat-resistant lining that can withstand the extreme temperatures and chemical reactions occurring in this area. Another common application is the lining of the bosh, which is the transition zone between the hearth and the stack of the blast furnace. The bosh is subjected to high temperatures and mechanical stresses due to the movement of the burden materials. Monolithic refractories with high thermal shock resistance and abrasion resistance are used to ensure the longevity and efficiency of the bosh. Monolithic refractories are also used for the lining of the stack and the tuyere area. The stack is the vertical part of the furnace where the reduction of iron ore takes place. The tuyere area is where the hot blast of air is injected into the furnace. Both of these areas require refractories that can withstand high temperatures, chemical reactions, and mechanical stresses. Furthermore, monolithic refractories are used for repairs and maintenance in blast furnaces. Due to the harsh conditions inside the furnace, the lining may deteriorate over time. Monolithic refractories can be easily applied as patching materials to restore the integrity of the lining and extend the furnace's lifespan. In summary, the typical applications of monolithic refractories in blast furnaces include lining the hearth, bosh, stack, and tuyere area, as well as for repairs and maintenance. These refractories provide excellent thermal shock resistance, abrasion resistance, and durability, making them essential for the efficient operation of blast furnaces in the iron and steel industry.

- Q: What are the advantages of using self-flow castables in the iron and steel industry?

- The advantages of using self-flow castables in the iron and steel industry are numerous. Firstly, these castables have excellent flowability, which allows for easy and efficient installation. This results in reduced labor costs and time savings during the installation process. Additionally, self-flow castables have high strength and excellent resistance to thermal shock. This makes them highly durable and capable of withstanding the extreme temperatures and thermal cycling conditions present in iron and steel applications. As a result, they provide long-lasting and reliable performance in these demanding environments. Furthermore, self-flow castables offer excellent dimensional stability, ensuring that the refractory lining maintains its shape and integrity even under high mechanical loads and thermal stresses. This feature is crucial in maintaining the structural integrity of the furnaces, ladles, and other equipment used in the iron and steel industry. Moreover, self-flow castables have low water requirements, reducing the risk of cracking and spalling during drying and firing. This leads to improved product quality and increased refractory lifespan. Overall, the advantages of using self-flow castables in the iron and steel industry include easy installation, high strength, thermal shock resistance, dimensional stability, and improved product quality. These benefits contribute to increased efficiency, reduced downtime, and cost savings for iron and steel manufacturers.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Monolithic Refractories for Iron and Steel Industry - High Alumina Based Mortar for Hot Blast Stove

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords