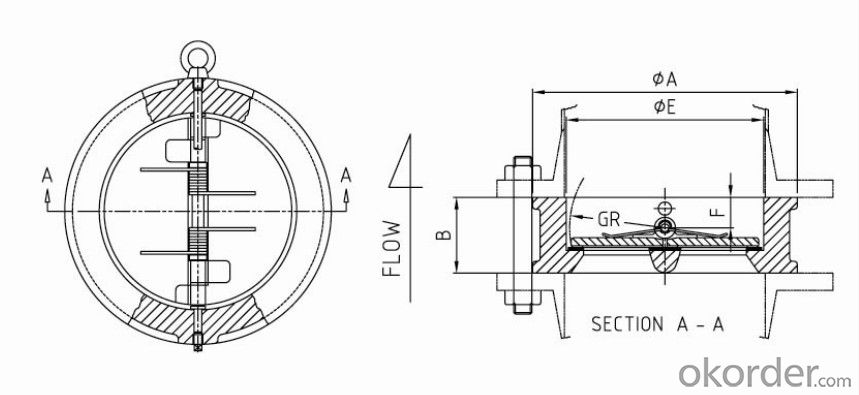

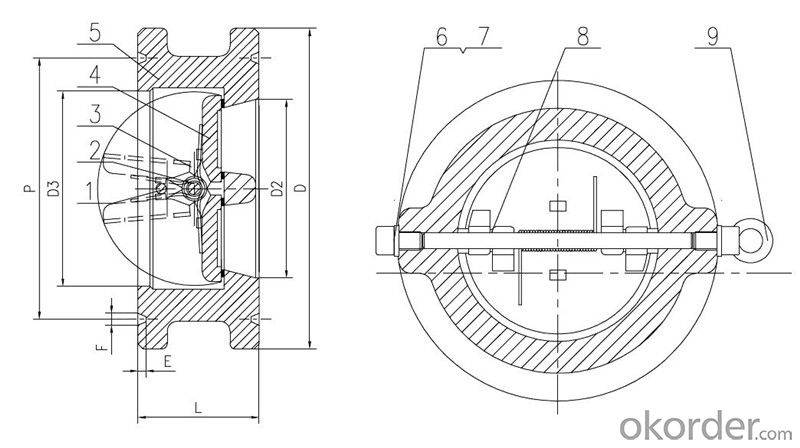

Swing Check Valve Wafer Type Double Disc DN 650 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: i would like to hear from anyone who has actually had the work done. i also would like to know if the valve worked.

- A backwater valve is basically a check valve that lets water flow in one direction only, away fom your system, and prohibits any other accumulation from entering into your system, like flood water etc. Yes they work very well unless they get full of junk and stuck open. You can install it yourself on the sewage line, they are about 50 bucks, its simple

- Q: I am being sent for a level 2 Ultrasound Thursday because my previous US showed one of the babies valves was enlarged. She said all 4 chambers were there but she was very vague on what this means. Care to shed some light?

- I don't know what this means in a fetus at 20 weeks since a lot of changes still lie ahead, but you can glean some info from the nature of this type of defect in adults. If the abnormality doesn't change and if no other abnormalities arise, the flaps of the affected valve will poke into one of the heart chambers. This situation is called valve prolapse. Look up mitral valve prolapse as an example. Typically a valve prolapse is not a serious defect, but if the prolapse is severe it might require treatment at some point in life or maybe even multiple treatments. What the heart will look like at birth is probably the bigger question. Some abnormalities signal a genetic defect that might cause other problems as well. Some defects cause a chain of problems in later steps of development. Your doc should have a good idea if any of these concerns exist. Maybe genetic testing will be suggested, but many defects occur with no explanation and they do not cause other complications. I would guess that after the chambers are developed, a dilated valve would be unlikely to cause any significant complications in later heart development, but this is just a guess.

- Q: Does a faulty pcv valve (Positive Crankcase Ventilation valve) cause excessive exhaust smoke ?

- Faulty Pcv Valve

- Q: I think on old AC units They had a different valve than the shrader. It might be called a king? Anyway, I can't get my gauge to read the pressure. The needles don't move at all. How can I measure, refill this type of HVAC?

- no offense,but i'm a little concerned that you have gauges and the knowhow to check freon,but dont know about different types of service / access valves.apply any advice at your own risk......anyway,,if you remove the large cap that covers the stem of the service valve you need to [ with gauges already connected] turn the stem clockwise to open it so your gauge can read the pressure,[ they make a special service valve wrench for this purpose,an adjustable wrench usually will work,but be careful not to strip the square end of the stem if its old and doesnt want to turn],,only turn the stem one or two times around,,DO NOT keep turning it clockwise until it stops or you will close the valve off....when finished checking with gauges,be sure to turn stem counterclockwise until it stops turning,,then you can safely remove gauges..if you remove gauges without turning stem counterclockwise,the the freon will blow out of the valve when gauges are removed,,not a pleasant experience,, be sure to where gloves and goggles,esp if you arent used to doing this......dan

- Q: my friend needs a flap valve replacement. does anyone no how serious this is, i dnt wanna lose my best friend?!!!

- Its heart surgery, which is riskier than many other surgeries, but valve replacement is routine procedure. There's a variety of different procedures that are used and several different types of replacement valves. Some valves can be repaired and some need to be replaced. Repairs usually give a person a normal or nearly normal valve that will last forever. Valve replacements don't work quite as wells as repairs and they usually need to be replaced in a decade or so. Most people can have the valved replaced by threading a scope through the arteries or using tiny incisions, but some people require open heart surgery. My friend had one of his valves replaced with a valve made from a pig heart and he was only in the hospital one night, and back to work a week later.

- Q: The atrioventricular valves will be open whenA. Atria are in diastole and ventricles are in systole B. Pressure in the ventricles is greater than the pressure in the great arteries C. The ventricles are being passively filled D. The ventricles are in isovolumetric contraction

- Answer: (c) The ventricles are being passively filled. During diastole, a normally-functioning mitral valve opens as a result of increased pressure from the left atrium as it fills with blood (preloading). As atrial pressure increases above that of the left ventricle, the mitral valve opens. Opening facilitates the passive flow of blood into the left ventricle. Diastole ends with atrial contraction, which ejects the final 20% of blood that is transferred from the left atrium to the left ventricle. This amount of blood is known as end diastolic volume (EDV), and the mitral valve closes at the end of atrial contraction to prevent a reversal of blood flow. Mitral valve also opens when right ventricle is passively filled.

- Q: Anyone know what causes a heart valve to leak? I had surgery to repair mine (mitral) a few months ago, and now I have a very mild leak.

- The valve isn't closing securly. If that's what you went in for, maybe the surgery wasn't done properly.

- Q: The pig heart is better than our heart but the valves can be used to help us.

- cape.uwaterloo.ca/che100projects/... They also use cow - bovine - for valve replacements.

- Q: Ok i dont know much about cars so if anybody could help out with this id appreciate it. Do i need to take my car in to get the PCV valve replaced or can i buy it and have it done in my driveway?Thanks....

- The PCV valve is about 3 inches long, just pull it out of the valve covers and replace it with the new one!!!

- Q: i have an old 79 malibu and its only got a 267 in it. I wouldnt buy new valve covers because its not worth it to me but i was thinking i could clean the ones i got up a little bit. i was thinking of painting them. What kind of paint should i use? and one other thing is the gaskets. I figure while i have them pulled off i should put new gaskets on. I read up about getting all the old stuff off but i was curious still about it. I was just looking at some average ones made of cork for 10 bucks. Do i lay the sealer downthen put the gasket on , then put the valve cover on?

- the best thing i could tell you is clean them good and when you put the gasket on dosent matter if its cork or not, but the silicon ones are better, is that to make sure that the mounting surface's are clean. and have no oil on them otherwise your gonna have a leak. as for the pain clean em good and it really dont matter which paint

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 650 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords