First-class Steel-work Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

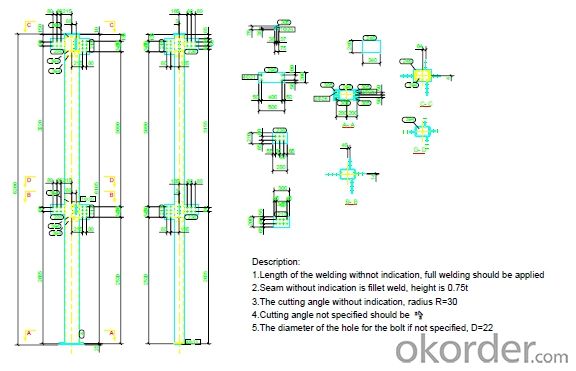

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

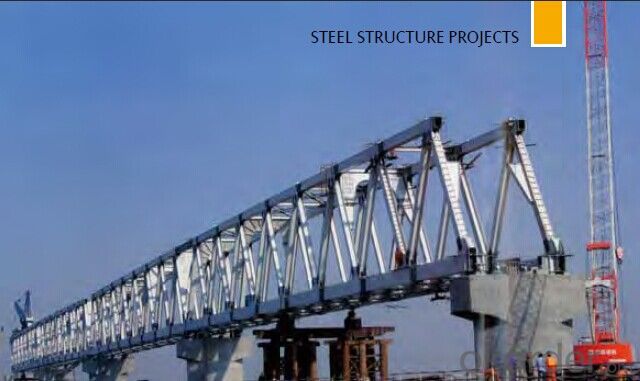

Project Reference:

Inner Mongolia Shangdu Power Plant is the main source

of west-east power transmission project with total

incestment of 5137 million Yuan. 1,900 tons for the steel

structure of the project with maximum thickness 60mm-

75mm.

- Q: How are steel structures designed for differential settlement?

- Differential settlement in steel structures can be addressed through various methods. One common approach is incorporating flexible connections or expansion joints between different sections of the structure. These connections allow for slight movements and rotations without subjecting the steel members to excessive stress. By utilizing these flexible connections, the structure can accommodate differential settlement, preventing the occurrence of cracks or other structural problems. Engineers may also design the steel structure with adjustable supports or leveling devices. These components can be modified or adjusted to account for differential settlement during construction or after the structure is in use. By regularly monitoring settlement and making necessary adjustments, the structure can maintain its stability and integrity. Another technique to tackle differential settlement is designing the steel structure with a reinforced foundation. This involves utilizing deep foundations like piles, caissons, or footings that extend below the expected settlement zones. The reinforced foundation helps distribute the load more evenly, reducing differential settlement and minimizing its impact on the steel structure. Furthermore, designers can employ soil improvement or ground improvement techniques to mitigate potential differential settlement. These methods involve modifying the properties of the underlying soil to enhance its strength or decrease its compressibility. By improving the soil conditions, differential settlement can be minimized, ensuring the steel structure remains stable and level. In summary, the design of steel structures for differential settlement involves a combination of flexible connections, adjustable supports, reinforced foundations, and soil improvement techniques. By implementing these strategies, engineers can guarantee that the steel structure can endure and adapt to differential settlement, maintaining its structural integrity and functionality.

- Q: What are the design considerations for steel structures in water or wastewater treatment plants?

- Some of the key design considerations for steel structures in water or wastewater treatment plants include corrosion resistance, durability, and ease of maintenance. Steel structures in these environments are constantly exposed to corrosive elements such as water, chemicals, and gases, so selecting the right type of corrosion-resistant steel is crucial. Additionally, the structures must be designed to withstand various loads, including the weight of equipment, water pressure, and seismic forces. Easy access for maintenance and repair is also essential, as regular inspections and upkeep are necessary to ensure the longevity and efficiency of the plant.

- Q: How are steel structures used in the construction of casinos?

- Steel structures are commonly used in the construction of casinos due to their strength, durability, and flexibility. Steel beams, columns, and frames provide a sturdy framework, allowing for large open spaces and unique architectural designs. Additionally, steel's fire resistance properties make it a safe choice for these high-occupancy buildings.

- Q: How are steel structures designed to resist lateral forces, such as wind or seismic loads?

- Steel structures are specifically designed to resist lateral forces, such as wind or seismic loads, through a combination of key design principles and structural elements. First and foremost, the design process begins with a thorough understanding of the specific site conditions, including the prevailing wind speed or seismic activity in the region. This information is crucial in determining the magnitude and direction of the lateral forces that the structure will likely experience. To resist these lateral forces, steel structures employ several key design principles: 1. Rigid Frame Systems: Steel structures often utilize rigid frame systems, where beams and columns are connected together to form a rigid framework. This system helps distribute the lateral forces throughout the structure, reducing the concentration of stress at specific points. 2. Bracing Systems: Steel structures incorporate bracing systems, which are designed to absorb and distribute lateral forces. These systems typically consist of diagonal steel members placed strategically throughout the structure, forming a triangulated pattern. The bracing members help resist lateral forces by transferring them to the foundation, reducing the risk of structural failure. 3. Shear Walls: In high-rise steel structures, shear walls are commonly used to resist lateral forces. These walls are typically placed at the perimeter or core of the building and are designed to absorb and transfer the lateral forces to the foundation. Shear walls are usually made of steel plates or reinforced concrete, providing additional stiffness and strength to the structure. 4. Moment-Resisting Connections: Connections between beams and columns in steel structures are crucial for resisting lateral forces. Moment-resisting connections are specifically designed to transfer the bending moments caused by lateral forces, ensuring that the structure remains stable and can withstand these forces without excessive deformation. Additionally, computer-aided design tools and advanced analysis techniques, such as finite element analysis, are employed to model and simulate the behavior of steel structures under various loading conditions. This allows engineers to optimize the design and ensure that the structure can withstand the expected lateral forces without compromising safety or performance. In conclusion, steel structures are carefully designed to resist lateral forces, such as wind or seismic loads, by incorporating rigid frame systems, bracing systems, shear walls, and moment-resisting connections. By implementing these design principles and utilizing advanced analysis techniques, steel structures can effectively withstand the lateral forces and ensure the safety and durability of the building.

- Q: What are the design considerations for steel structures in high-rise buildings?

- Some key design considerations for steel structures in high-rise buildings include: 1. Structural stability: Steel structures must be designed to withstand various forces such as wind, seismic activity, and vertical loads. Special attention is given to the selection of appropriate steel sections and connections to ensure stability. 2. Fire resistance: High-rise buildings require fire-resistant steel structures to prevent the spread of fire and maintain the structural integrity. Fire protection measures like fireproofing coatings or encapsulated fire-resistant materials are incorporated into the design. 3. Material strength: Steel used in high-rise structures should have high tensile strength and stiffness to handle the loads and stresses imposed on the building. The selection of steel grades and their properties is crucial for ensuring structural safety and performance. 4. Durability and maintenance: Steel structures should be designed for long-term durability, considering factors like corrosion protection, maintenance access, and resistance to environmental conditions. Proper protective coatings and maintenance plans are essential to extend the lifespan of steel components. 5. Constructability: Design considerations should account for the ease of fabrication, transportation, and assembly of steel components in high-rise construction. Modularization and pre-fabrication techniques can be utilized to streamline the construction process and minimize on-site labor requirements. 6. Architectural integration: Steel structures in high-rise buildings often need to be integrated with architectural elements, such as facades, curtain walls, and interior spaces. Design considerations should ensure that the steel structure supports the desired architectural aesthetics and functional requirements. 7. Sustainability: Designing steel structures in high-rise buildings with sustainable practices in mind is important. This includes optimizing material usage, incorporating recyclable materials, and considering energy efficiency measures to reduce the environmental impact of the building.

- Q: What are the advantages of using steel in the construction of retail outlets?

- There are several advantages of using steel in the construction of retail outlets. Firstly, steel is a highly durable material, providing long-lasting structural integrity to the building. This durability ensures that retail outlets can withstand heavy foot traffic and other potential stressors without compromising safety or stability. Additionally, steel is known for its strength and versatility. It allows for the construction of large open spaces without the need for excessive support columns, providing more flexibility in store layout and design. This flexibility is crucial for retail outlets as it enables easy reconfiguration of store layouts to adapt to changing trends or merchandise displays. Moreover, steel is a cost-effective material for construction. It is relatively affordable compared to other building materials, and its lightweight nature reduces the need for extensive foundation work. This cost-effectiveness is particularly beneficial for retail outlets that often have tight budgets and require efficient construction timelines. Furthermore, steel is a sustainable choice for retail outlets. It is a recyclable material, making it environmentally friendly and reducing the carbon footprint of the construction process. Steel structures can also be designed to incorporate energy-efficient features, such as insulation and solar panels, further reducing environmental impact and operational costs. In summary, utilizing steel in the construction of retail outlets offers advantages like durability, strength, flexibility, cost-effectiveness, and sustainability, making it an ideal choice for creating functional and visually appealing retail spaces.

- Q: How do steel structures provide resistance against blast-induced progressive collapse?

- Several mechanisms contribute to the ability of steel structures to resist blast-induced progressive collapse. Firstly, steel possesses excellent material properties that enable it to absorb and distribute blast energy effectively. Being a ductile material, steel can undergo significant deformation before failing. Therefore, when subjected to blast loads, steel members can absorb a substantial amount of energy by undergoing large plastic deformations, thereby reducing the impact on the overall structure. Moreover, steel structures are designed with both redundancy and robustness in mind. Redundancy ensures that there are multiple load paths within the structure, allowing the redistribution of load in the event of a member failure. Consequently, the collapse does not propagate and is limited in extent. On the other hand, robustness refers to the structure's ability to withstand local failures without undergoing catastrophic collapse. Steel structures are designed to have sufficient reserve capacity to withstand the loss of one or more members, even under extreme blast loading conditions. Furthermore, steel structures commonly incorporate blast-resistant details and connections. These specifically engineered components are designed to withstand the dynamic forces generated by an explosion. Blast-resistant connections, for instance, prevent the sudden release of energy by maintaining the integrity of structural elements. By preventing critical connections from failing, the blast load is effectively distributed throughout the structure, minimizing the potential for progressive collapse. Lastly, steel structures can be retrofitted to enhance their resistance against blast-induced progressive collapse. Retrofitting measures may include strengthening critical connections, adding supplemental bracing or reinforcement, or installing blast-resistant cladding systems. Such retrofits significantly improve the structural response to blast loads and mitigate the risk of progressive collapse. In conclusion, the resistance of steel structures against blast-induced progressive collapse is achieved through their material properties, structural redundancy and robustness, blast-resistant details and connections, and the potential for retrofitting. These features ensure that steel structures can withstand the dynamic forces generated by an explosion, prevent the collapse from spreading, and enhance the safety and resilience of the overall structure.

- Q: How is the steel structure foundation checked and accepted?

- The column position in the column surface measuring axis of projectile.Level of plinth elevation. Concrete plinth elevation 50 ~ 60 mm for general casting (compared with steel column base design, installation in elevation) with steel plate or early adoption by plasma plate leveling.When using the steel plate support plate, steel plate area should be determined according to the fastening force and compressive strength, concrete of foundation base plate two times before grouting at the bottom of the column load and anchor bolt. The contact between the shim and the base and the bottom of the column should be smooth and tight.When the cushion plate is used, the shrinkage free mortar shall be adopted. The strength of the mortar block should be higher than that of the base concrete before the lifting of the column, and the mortar pad should have enough area to meet the requirements of the load.

- Q: What are the different types of steel cladding used in buildings?

- There are several types of steel cladding commonly used in buildings, including galvanized steel, stainless steel, weathering steel, and pre-painted steel. Each type offers unique characteristics and benefits, such as corrosion resistance, durability, aesthetic appeal, and ease of maintenance. The choice of steel cladding depends on factors like the building's location, desired appearance, and budget.

- Q: How do steel structures contribute to the overall architectural expression of a building?

- Steel structures play a crucial role in shaping the overall architectural expression of a building. With their inherent strength and versatility, steel structures allow architects to achieve bold and innovative designs that would be challenging or impossible to realize using other materials. One of the key contributions of steel structures to the architectural expression of a building is their ability to create large, open spaces. The strength-to-weight ratio of steel allows for the construction of long-span roofs and wide-open floor plans, minimizing the need for internal columns or load-bearing walls. This not only enhances the aesthetic appeal of the building but also provides the flexibility to create dynamic and functional spaces. Moreover, steel structures offer a sense of lightness and transparency to a building's design. The slender profiles and minimalistic nature of steel elements allow for the creation of visually striking features such as cantilevers, suspended floors, and large glazed areas. These elements not only establish a strong visual connection between the interior and exterior but also provide a sense of modernity and elegance. Steel structures also contribute to the overall architectural expression through their ability to accommodate complex geometries. Unlike traditional building materials, steel can be easily fabricated into various shapes and forms, enabling architects to explore unconventional designs. This versatility allows for the creation of iconic structures, such as curvilinear facades or intricate structural patterns, which can make a building stand out and become a landmark in its own right. Furthermore, steel structures can enhance the sustainability of a building, which has become an increasingly important aspect of architectural expression. Steel is a highly recyclable material, and its use in construction can contribute to reducing the environmental impact of a building. Additionally, steel structures can support the integration of renewable energy systems, such as solar panels or wind turbines, further enhancing the building's overall expression of sustainability and innovation. In conclusion, steel structures have a significant impact on the overall architectural expression of a building. They enable architects to create spacious, open environments, incorporate light and transparency, explore complex geometries, and contribute to the sustainability of a building. By pushing the boundaries of design possibilities, steel structures help to shape unique and visually striking buildings that leave a lasting impression on both the inhabitants and the surrounding urban landscape.

Send your message to us

First-class Steel-work Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords