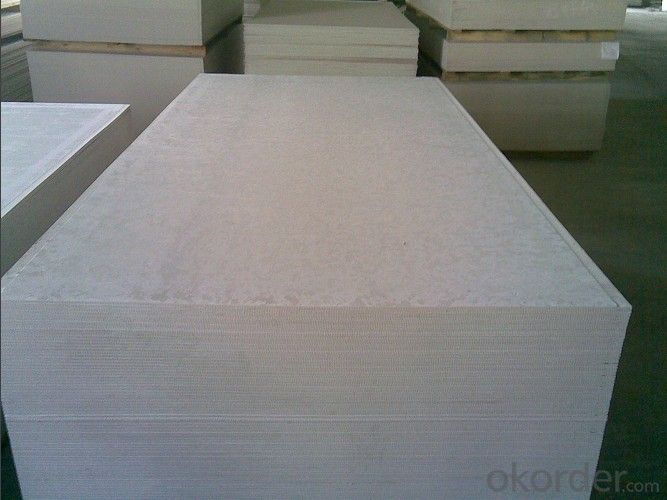

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1. Interior and exterior wall; Furred ceiling

2. Insulation materials, floor; Road barrier

3. Sound-adsorbing wall & suspended ceiling

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: I need to cut a curved piece of cement board. Will it work to score it with a utility knife, then break it? Thanks.

- Yes it cuts just like drywall, scrore then snap.Score a bit deeper though.

- Q: I have asbestos shingles and i need to vent a portable a/c so i'm going to replace a few shingles with fiber cement board so i can cut them. i heard these things are a nightmare to cut.

- Go to any rental place they rent these drills and bits that have diamond tips for cutting concrete. And use water to hold down the dust. Should have any size you need.

- Q: Do you have to tape and fill seams on cement board when applying ceramic tile over it like when doing drywall?

- Yes, you'll use fiberglass mesh tape to tape the seams and a coating of thin-set mortar

- Q: okay so im making a notebook collage n i was wondering if i can use rubber cement...oh and does it dry clear because i added some now and it's kinda dark colored and i don't want people to see the stains.. i dont have an eraser or anything like that!

- I used it many times to temporarily glue photography artwork to the matting board. The good thing about it -- it is removable when dry. Just scrub it lightly with a paper towel or even with your fingers. I buy my rubber cement in art supply stores, it is not dark colored at all and they also sell a convenient big rubber eraser for it. Beware: it is not to create a permanent bond; the photos will fall off in time.

- Q: i would also like to know what products might help me. Thanks :) Oh, and the type of board i got is called hardi-bord... i didnt know if that might help.

- This Site Might Help You. RE: Do I need to water seal a cement board that would sit behind tiles in my shower before i tile it? i would also like to know what products might help me. Thanks :) Oh, and the type of board i got is called hardi-bord... i didnt know if that might help.

- Q: What is the waterproof material for the bathroom wall?

- Bathroom cut off the material three, tempered glass Tempered glass belongs to safety glass. In fact, the use of chemical or physical methods, the formation of compressive stress on the glass surface, the glass bear the external force when the first to offset the surface stress, thereby enhancing the carrying capacity, enhance the glass self-resistance Wind pressure, cold and heat, impact and so on. Flat steel, curved glass is a safety glass. Widely used in high-rise building doors and windows, glass curtain wall, indoor partition glass, lighting ceiling, sightseeing elevator channel, furniture, glass fence and so on.

- Q: how much space should i be giving over my tub? ill be infront of the bath tub lip because of some issues trying to make everything flush.ive heard to just butt it up against the tub, but then ive heard give a 1/8 of a space for grout. any1 know?

- The cement board goes over the lip of the tub to help prevent water from running down behind the tub. a small gap between tub and board is fine. When the tile is grouted, the gaps between the tub and tile will be filled. (the final step is to caulk the corners and between the tub and tile). The gaps in the cement board are filled with thin set and mesh tape before tiling. I have never used mesh tape between the tub and cement board. I fill the space with thin set. If it's installed properly and screwed down sufficiently, cement board should not move. It really doesn't expand/contract with heat/cold much. It's very stable.

- Q: My husband fixed the faucet in the tub around two years ago. He cracked one of the tiles. We bandaged the area, but water has been getting behind the tiles. So, we have water damage. Plus, there is this weird white fungus looking stuff that is growing in some of the grout lines. I don't want to just put a liner over this mess. I would like to pull all the tile off and put cement board up (the house is old and it has sheet rock behind the tile), so i can start fresh. Will the liner hold up the same if it is glued to cement board rather than tile?

- You def need to see what is behind that tile so you cannot just cover it, as you suspected. There should never have been dry wall there in the first place. You need green board. Take everything down...let it dry back there for 3 days even using fans if necessary. Then put up green board, then the wall liner.

- Q: in other words: Houses in Mexico are well done.In USA are disposable.

- Price!!! Im building a house in Mexico. Its the first house I have ever built so im learning a lot. But let me tell you from my experience. Building out of brick and cement is a lot more expensive and difficult than wood. If built right, a brick house can last for centuries. A brick house can have all the look of a wood house too. Which is what most american like and are used to. The cost though, is greater for the bricks. Brick houses are still build in the US, but not too often.

- Q: Iam building a dry stack wall and the home store said to use cement broad and wire mess .

- I assume you mean cement board and wire mesh. I would use the mesh - it's cheap and it will improve the stability of the finished construction.

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords