High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

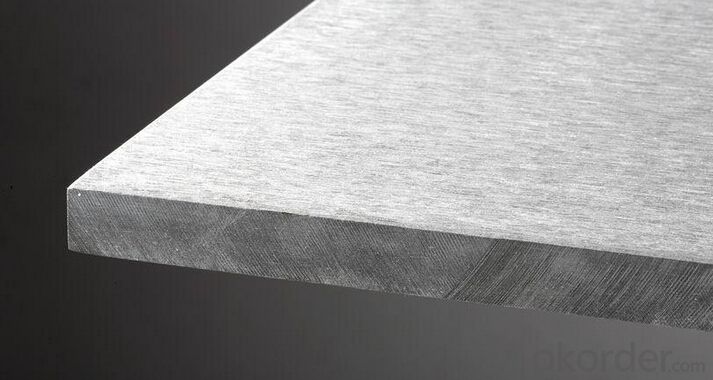

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: Can cement board be directly approved for cement?

- The cement board is made of stones, sand, cement and steel.

- Q: Can cutting the steel cutting machine cut the cement board?

- Can not cut the reinforced toothless saws are grinding wheel pieces, while cutting the concrete slabs to use the toothless alloy steel saw blade.

- Q: Has anybody made a claim for and been paid for the cement board siding class action lawsuit?

- Dont okorder has some good examples of past class action lawsuits and for a really good read, read Grisham's the king of Torts. Right now I am actually a part of a class to recover FOREX fees on my credit card. I have lost probably a few hundred dollars i expect to be granted $5! Wahoo!

- Q: We are building a new house and I am going to install tile in the bathrooms myself, we have the drywall hung and will be sanded in the next day or two. My question is, can I go ahead and hang the Cement backer board in the showers? or do I need to wait until the drywall is sanded or primed? Thanks :o)

- Hang it now, you'll be fine.

- Q: Tile seems to be an expensive options. Want a finished look for less than tile

- Its just a thought, but after watching countless hours of the home and garden channel some people tend to paint over concrete to spruce it up or to make mismatched tones even.

- Q: How do the fluorocarbon paint on the external wall of the cement pressure plate?

- Substrate requirements: Cement pressure plate to be clean, dry, non-polluting.

- Q: 60 thick foam cement board Ⅱ how much noise

- Product density is light, the volume of dry, the density of about 250kg / cubic, the board through the National Testing Center 1.5 million times the anti-fatigue vibration test, the board and the steel structure as a whole, can reach 9 earthquake.

- Q: Do you have a living room with a cement board?

- Wooden cement board ceiling with fire, moisture-proof function, the use of a wide range, often as a floor, ceiling or TV main wall, wall decoration materials. As the color of diversification, according to the style of home to do color selection and match.

- Q: i can ollie on a rug ok but then on the cement my board moves and the back wheels dont get up i know i am doing the ollie right but when i try it on the cement the board moves and the back wheels dont go up i really need help because most of my friends skate and they are really good and i would like to start skating but i dont know if i am good please give me some tips about ollieing on the cement thanks!

- Your pushing your board back with your feet. Try not to do this and practice. The only way to be good in skateboarding is practicing everything hard.

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords