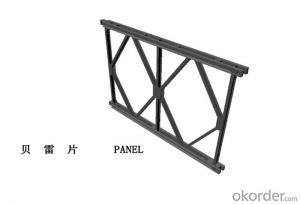

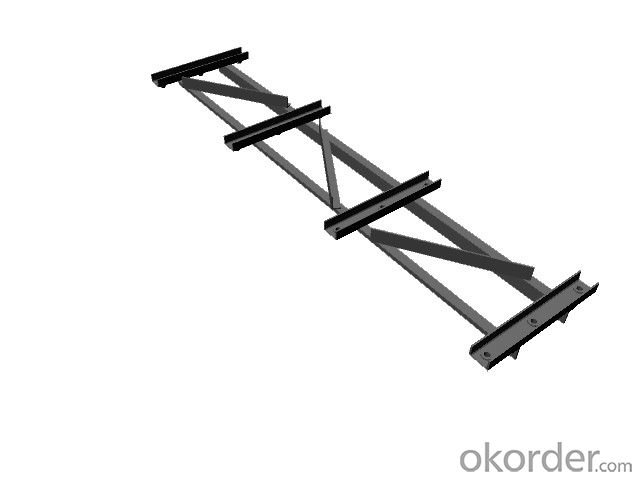

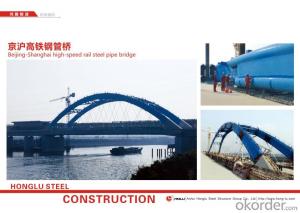

HD200 High quality portable bailey steel bridge components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The compact 200 panel bridge is similar to the compact 100 panel bridge from their appearance. The difference is its increased panel height to 2.134m. It employed the method of alternating joints between Reinforcement Chords and the joints between panels. This method can decrease inelastic deformation caused by the oversized pinholes. Pre-arch method is used to additionally cut down mid-span and vertical deflection to a larger degree. Bolt-connected components use the orienting sleeve- fixing method to increase accuracy of connections. Shear is created in orienting sleeves and tension is developed in bolts, which increase the usage life of the bolts and ensure the safety of panel bridges. Wind resistant brace is made to be composite type and is connected to transom/girders to improve overall stability of panel bridges.

The part between braced frame and panels is fixed through bridging so as to prevent the whole bridge from side bending. After the erection, there will be a pre-arched degree over the span of the bridge. Besides it can be assembled into single-lane bridges. The compact 200 panel bridge can also be assembled into double lane bridge, hence it broadens its application range. It is suitable for the load designs of HS-15, HS-20, HS-25 and pedrail-50 etc.

- Q: How are steel structures designed for thermal comfort?

- Steel structures can be designed for thermal comfort through various strategies that aim to regulate the internal temperature and enhance occupants' comfort. One of the key considerations is insulation. By incorporating effective insulation materials in the walls, roofs, and floors of steel structures, heat transfer can be minimized, thereby reducing heat gain or loss from the external environment. This insulation helps maintain a stable internal temperature, reducing the need for excessive heating or cooling. Another aspect of thermal comfort design for steel structures is the integration of efficient HVAC (heating, ventilation, and air conditioning) systems. These systems can be designed to provide adequate heating or cooling based on the specific requirements of the building and its occupants. By ensuring proper airflow and temperature control, occupants can experience a comfortable indoor environment throughout the year. In addition to insulation and HVAC systems, other design considerations include the orientation and placement of windows and shading devices. By strategically locating windows to maximize natural light while minimizing direct sunlight exposure, passive solar heating can be utilized to provide additional warmth during colder months. Shading devices such as blinds or overhangs can also help reduce solar heat gain during warmer months, preventing overheating. Furthermore, the selection of appropriate building materials is crucial in steel structure design for thermal comfort. For instance, utilizing high-performance glazing with low solar heat gain coefficients can help reduce unwanted heat transfer. Additionally, incorporating thermal mass materials, such as concrete or stone, in the building envelope can help regulate temperature fluctuations by absorbing and releasing heat slowly. Lastly, the use of advanced technologies, such as smart controls and energy management systems, can optimize energy consumption and enhance thermal comfort. These systems can monitor and adjust temperature, humidity, and ventilation levels based on occupancy patterns and weather conditions, ensuring a comfortable and energy-efficient indoor environment. Overall, steel structures can be designed for thermal comfort by implementing insulation, efficient HVAC systems, strategic window placement, shading devices, appropriate building materials, and advanced technologies. By considering these factors, architects and engineers can create steel structures that promote a comfortable and sustainable living or working environment.

- Q: What are the different types of steel coatings used in structures?

- There are several different types of steel coatings used in structures, including galvanized coatings, epoxy coatings, powder coatings, and metallic coatings. Galvanized coatings involve applying a layer of zinc to the steel, providing protection against corrosion. Epoxy coatings are a type of paint that is applied to the steel surface, offering resistance to chemicals, abrasion, and corrosion. Powder coatings involve electrostatically applying a dry powder to the steel, which is then cured under heat to form a hard, durable finish. Metallic coatings, such as aluminum or zinc, are applied to the steel through a process like galvanization, providing both corrosion resistance and aesthetic appeal.

- Q: How are steel structures used in educational laboratories and research facilities?

- Steel structures are commonly used in educational laboratories and research facilities due to their strength, flexibility, and cost-effectiveness. Steel beams and columns provide the necessary support for heavy laboratory equipment and allow for large open spaces, facilitating easy reconfiguration of the space as research needs evolve. Additionally, steel structures are resistant to fire and have excellent seismic performance, ensuring the safety of the facility and its occupants.

- Q: What are the considerations for steel structure design in coastal areas?

- To ensure the longevity and durability of steel structures in coastal areas, it is necessary to take several factors into account: 1. To prevent rust and degradation, it is important to use corrosion-resistant materials and protective coatings in steel structures exposed to saltwater, humidity, and atmospheric conditions. 2. The choice of steel alloys is crucial in coastal areas. Stainless steel or galvanized steel are commonly used due to their high resistance to corrosion, providing additional protection against the effects of saltwater and moisture. 3. Structural design should consider the impact of strong winds, waves, and salt spray. Adequate structural systems, such as bracing and reinforcements, must be implemented to withstand these forces and prevent damage or failure. 4. Foundation design can be challenging in coastal areas with sandy or loose soil. Proper site investigation and soil analysis should be conducted to determine the appropriate foundation design, which may include deep foundations or pile systems to ensure stability and prevent soil erosion. 5. Regular maintenance and inspection are essential for steel structures in coastal areas. Routine inspections should be carried out to identify signs of corrosion or damage, and prompt repairs or maintenance should be conducted to prevent further deterioration. 6. Environmental impact should also be considered in the design of steel structures in coastal areas. The use of sustainable materials, such as recycled steel or low-carbon steel, can reduce the carbon footprint. Additionally, measures should be taken to protect the surrounding ecosystem and habitats during construction and operation. In conclusion, designing steel structures in coastal areas requires careful consideration of corrosion resistance, material selection, structural design, foundation design, maintenance, and environmental impact. By addressing these factors, a steel structure can be constructed to withstand the challenging coastal environment and ensure long-term performance and safety.

- Q: How are steel structures designed to provide adequate ventilation and air circulation?

- Steel structures are designed to provide adequate ventilation and air circulation through a variety of methods. One of the primary ways this is achieved is through the use of strategically placed windows and openings in the structure. These windows and openings allow for the natural flow of air, creating a cross-ventilation effect that helps to circulate fresh air throughout the building. In addition to windows and openings, steel structures can also incorporate ventilation systems such as ductwork and fans. These systems are designed to actively move air throughout the building, ensuring that fresh air is constantly circulating. Another important aspect of steel structure design is the consideration of thermal comfort. Steel structures can incorporate insulation materials to help regulate the temperature inside the building and prevent excessive heat or cold from affecting the ventilation and air circulation. Insulation also helps to reduce energy consumption by minimizing the need for heating or cooling systems. Moreover, the layout and arrangement of the interior spaces within a steel structure can also contribute to adequate ventilation and air circulation. Open floor plans or the use of partitions and walls that do not fully extend to the ceiling can facilitate the movement of air throughout the building. Overall, steel structures are carefully designed to provide adequate ventilation and air circulation through a combination of natural and mechanical methods. This ensures a healthy and comfortable environment for occupants while also promoting energy efficiency and sustainability.

- Q: Can steel structures be easily modified or expanded?

- Yes, steel structures can be easily modified or expanded due to their inherent strength, durability, and flexibility. Steel is a highly malleable material that can be easily reshaped or cut to accommodate changes or additions to the structure. Additionally, steel structures allow for the integration of new components or sections, making it relatively straightforward to expand the existing framework.

- Q: What are the different types of steel roofs and skylights used in buildings?

- There are various types of steel roofs used in buildings, including corrugated steel roofs, standing seam steel roofs, and steel shingle roofs. As for skylights, steel-framed skylights are commonly used in buildings, along with steel-supported glass roofs and steel-clad skylights.

- Q: What are the design considerations for steel automotive plants?

- To create a safe and efficient manufacturing facility for steel automotive plants, several design considerations must be taken into account. These include: 1. Optimizing facility layout: The plant's layout should be designed to optimize workflow, minimize material handling, and promote efficient production processes. This involves ensuring a smooth flow of materials, providing sufficient space for equipment and machinery, and creating clear pathways for workers. 2. Ensuring structural integrity: Steel plants require a strong and durable structure to support heavy machinery, overhead cranes, and the storage of raw materials. The design should consider the weight and load-bearing capacity of the equipment, as well as factors like seismic activity and extreme weather conditions. 3. Prioritizing safety measures: Safety is of utmost importance in automotive plants, so the design should incorporate features such as fire protection systems, emergency exits, proper ventilation, and the use of non-combustible materials. Additionally, ergonomic considerations should be made to minimize workplace injuries and ensure a safe environment for employees. 4. Emphasizing energy efficiency: With the automotive industry moving towards sustainability, energy efficiency is a significant design consideration. Introducing energy-saving features like LED lighting, efficient HVAC systems, and renewable energy sources can help reduce operational costs and environmental impact. 5. Considering environmental factors: Steel plants often have a significant environmental footprint, making it crucial to design with sustainability in mind. This may involve implementing waste management systems, water recycling processes, and using green building materials to minimize the impact on the surrounding ecosystem. 6. Allowing for flexibility and future expansion: The automotive manufacturing industry is dynamic, so plant designs must be flexible to accommodate changes in production processes and technological advancements. Additionally, the design should consider the potential for future expansion or reconfiguration to meet the demands of a growing market. 7. Integrating technology: Advanced technologies such as automation, robotics, and data analytics systems can enhance efficiency and productivity in automotive plants. The design should account for the integration and placement of these technologies to maximize their benefits. In conclusion, the design considerations for steel automotive plants encompass various factors, including facility layout, structural integrity, safety, energy efficiency, environmental sustainability, flexibility, and the integration of technology. A well-designed plant that addresses these considerations can provide a competitive advantage in the automotive industry while ensuring a safe and productive working environment.

- Q: How are steel structures used in the construction of food processing facilities?

- Food processing facilities widely utilize steel structures due to the multitude of advantages they offer. One of the key factors contributing to their popularity is the durability and strength that steel provides, essential for supporting the heavy machinery and equipment used in food processing. With its high load-bearing capacity, steel can withstand the weight of large processing equipment, storage tanks, and conveyors. Furthermore, steel structures offer flexibility in both design and construction. They can be easily customized to meet the specific requirements of a food processing facility. Steel frames can be constructed in various shapes and sizes, allowing for efficient utilization of available space and accommodating specific equipment layouts. This adaptability also permits future expansion or modifications as the facility's needs evolve. Another significant benefit of steel structures lies in their resistance to corrosion and pest infestations. Given the strict hygiene standards in food processing facilities, steel provides a hygienic and easy-to-clean environment. Unlike other materials, steel does not absorb moisture or harbor bacteria, ensuring food safety and minimizing the risk of contamination. Steel structures also bring speed and efficiency to the construction process. Pre-fabricated steel components can be manufactured off-site and then swiftly assembled on-site, reducing construction time and costs. This proves particularly advantageous in the fast-paced food processing industry where time is of the essence. Moreover, steel is an environmentally friendly choice for food processing facilities. It is a recyclable material and promotes sustainability by reducing waste. Additionally, steel structures are energy-efficient as they can be designed to incorporate insulation, natural lighting, and ventilation systems, thereby reducing energy consumption and operating costs. In conclusion, steel structures play a crucial role in the construction of food processing facilities. Their strength, durability, flexibility, and hygienic properties make them an ideal choice for supporting heavy machinery, accommodating specific layouts, and meeting stringent hygiene standards. Furthermore, their quick construction time, recyclability, and energy efficiency contribute to the overall sustainability of food processing facilities.

- Q: How are steel structures used in the construction of hotels and resorts?

- Steel structures are widely used in the construction of hotels and resorts due to their numerous benefits. Firstly, steel is a strong and durable material, making it ideal for supporting large and complex structures like hotels and resorts. The use of steel ensures that these buildings can withstand extreme weather conditions, earthquakes, and other natural disasters, providing a safe and secure environment for guests. Additionally, steel structures offer flexibility in design, allowing architects and engineers to create unique and visually appealing buildings. The versatility of steel allows for open floor plans, large spans, and the integration of various architectural features, such as glass facades or soaring atriums. This flexibility also allows for easy expansion or modification of the buildings in the future, accommodating the changing needs of the hotel or resort. Furthermore, steel structures enable faster construction times compared to traditional building materials. The components of a steel structure can be pre-fabricated off-site, reducing construction time on-site. This not only leads to cost savings but also allows hotels and resorts to be operational sooner, generating revenue at an earlier stage. Moreover, steel is an environmentally friendly material. It is highly recyclable, meaning that steel components can be reused or repurposed at the end of a building's life cycle. The use of steel in construction also reduces the need for timber, which helps to preserve forests and ecosystems. In conclusion, steel structures are extensively used in the construction of hotels and resorts due to their strength, durability, flexibility in design, faster construction times, and environmental benefits. These structures provide a solid foundation for creating aesthetically pleasing, safe, and sustainable buildings that meet the ever-evolving demands of the hospitality industry.

Send your message to us

HD200 High quality portable bailey steel bridge components

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords