Hardware Steel Wire in Electro and Hot -Dipped Galvanized

- Loading Port:

- Yantai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hardware Steel Wire in Electro and Hot -Dipped Galvanized

1. Structure of Steel Wire in Electro and Hot-Dipped Galvanized:

Steel Wire in Electro and Hot-Dipped Galvanized is made with choice mild steel, through wire drawing, wire galvanizing and other processes. Galvanized iron wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

Steel Wire in Electro and Hot-Dipped Galvanized can be supplied in the form of coil wire, spool wire or further processed into straightened cut wire or U type wire. It is mainly used in construction, express way fencing, binding of flowers and wire mesh weaving.

2. Main Features of Steel Wire in Electro and Hot-Dipped Galvanized:

• Antirust

• Shiny silvery color

• High strength

• Durable

• Versatile

• Good visual effect

3. Steel Wire in Electro and Hot-Dipped Galvanized Images

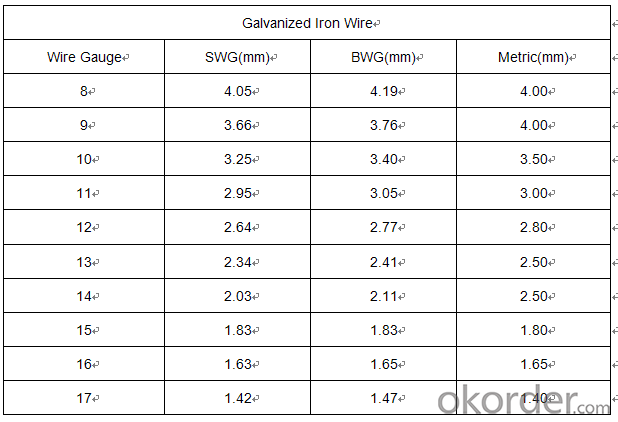

4. Steel Wire in Electro and Hot-Dipped Galvanized Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your products?

One of the most biggest manufacturer & supplier of wires and wire mesh,is a large-scale professional Steel Wire in Electro and Hot-Dipped Galvanized factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world.Different kinds of wires and mesh are available according to customer’s requirements.

② How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;Our company has good marketing network and abundant operation experience. Galvanized Iron Wire are sold to all parts of the country, at the same time, exported to Southeast Asia,The management theory is based on sincerity, keeping forging ahead. We have accumulated a whole set of marketing experience, having already become a local leader engaged in steel products.

③ How long can we receive the product after purchase?

In the purchase of Steel Wire in Electro and Hot-Dipped Galvanized within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: So earlier my passenger low beam wouldn't turn on. i went and bought a circuit tester and found out a wire located here _-_ lt;=== (the bottom right plug on the socket) that wire wont light up. i bought a socket at the same time, but i dont know how to replace it. and even if i did.. i don't see how that would fix the wire.It's possible the wire is fine. but i cleaned the socket and all that and still nothing.any advice would be great. i really need to drive at night1994 GMC jimmy

- The wire that leads to your socket may be worn or damaged. Find out which wire is not working. Use a meter that has a sharp probe, so you can stab the wire with the probe and see if it is putting out the electricity, up the wire from where you put the socket on. If the wire is not working, but off the part of the wire that is not working and splice in a new piece of wire and attach to the socket. Hopefully this will help you.

- Q: I want to connect one of my rear sony speakers along the baseboard to my receiver. The specs say that the wire comes with 4 terminal blocks, with 4 connections on each terminal. My question is what will connect to what? Will the speaker attach the the flat wire cable that will attach to the original speaker cable which will connect to the receiver? It will be much appreciated.

- You will end up using a combination of regular speaker wire and the flat wire. Run the flat wire along the baseboard. The ends of the flat wire should go as close to the receiver and speakers as it will reach. Attach the terminal blocks to the flat wire. Connect the receiver's right and left rear speaker outputs to the terminal block at the receiver end of the flat cable using two short lengths of two conductor speaker wire. Then do the same thing at the speaker end of the flat wire. Since the flat wire cannot connect directly to the receiver or speakers, you need to use regular speaker wire to connect the flat wire to the equipment at each end. Since the flat wire is four conductors, it can carry both the right and left rear speaker signal at the same time.

- Q: A load of 125 kip is being held by 3 wires all going up. The Wire one goes straight from the load to the horizontal. Wire 2 and 3 form a V on top of wire 1 and are 30 degrees from wire 1. This is a 2-D problem.

- You need to use summation of forces. Wires 1 and 2 are gonna have the same tension on them, just in opposite directions. so in the x direction, Fx=125cos(30)+125cos(150) (the vertical wire doesn't contribute to the x-direction forces and I choose 150 because the wire on the left really has an angle of 180-30 or 150) in the y direction, Fy=125sin(30)+125sin(150)+125sin(90) (The vertical wire is a 90 degree angle) Tension=sqrt( Fx^2 + Fy^2 )

- Q: how to connect the wiring from car stereo to amplifier

- The consistent potential twine is nearly a small direct line from the battery, as in it is many times warm, yet once you have been placing it to the useful of the upload-ons it could have in basic terms been becoming a circuit. it is to no longer say which you probably did no longer short out the wiring some incorrect way and that i'm unsure what the twine grew to become into which you genuinely touched with the consistent, yet it is many times run from the useful part as a relentless, till you have a grounded useful electric equipment on your motor vehicle. you does not in an '89 Escort till you probably did that your self. Wiring could be with any luck fused, even regardless of the indisputable fact that i do no longer understand how some distance back the fusing may well be, no count number if or no longer this is each and every of the previously to the fuse field or a separate fuse closer to the wiring.

- Q: THERMOSTAT WIRING

- What Sickwillie said.

- Q: Ok, I am having trouble installing a new car radio in my 97' Honda Civic Lx. It's just a basic pioneer cd player.. I matched all the colored wires up and still nothing. My brother had told me something about + - for example do i hook the green stripped wire with a flat green wire? Vice versa.. Help please.. Also If you know of a web site with diagrams?

- Car Stereo Radio Wiring Diagram - 1997 Honda Civic Radio Constant 12V+ Wire: Blue/White Radio Switched 12V+ Wire: Yellow/Red Radio Ground Wire: Black Radio Illumination Wire: Red/Black Radio Dimmer Wire: n/a Front Speaker Size and Location: 6 1/2″ Doors Left Front Speaker Wire (+): Blue Left Front Speaker Wire (-): Gray/Black Right Front Speaker Wire (+): Red/Green Right Front Speaker Wire (-): Brown/Black Rear Speaker Size and Location: 6″ x 9″ Rear Deck Left Rear Speaker Wire (+): Blue/Yellow Left Rear Speaker Wire (-): Gray/White Right Rear Speaker Wire (+): Red/Yellow Right Rear Speaker Wire (-): Brown/White

- Q: How much wire is required?

- Length of wire is L = R*A/p SI units must be used, so convert radius to meters: r = 0.0254 / 64 m using 25.4mm = 1 inch r = 3.969*10^-4 m (0.3969mm) So cross-sectional area is A = pi*(3.969*10^-4)^2 m^2 A = 4.95*10^-7 m^2 The average resistivity of nichrome is p = 1.1*10^-6 ohm-meter So the required length of wire is L = 2.2 ohm * 4.95*10^-7 m^2 / 1.1*10^-6 ohm-meter L = 0.990 m

- Q: What's the best kind of wire to use that can stand being kilned?

- that really depends what you want to do and how high you are going to fire. Generally nichrome 80/20 wire should be OK until cone 9. Then there is Kanthal which will withstand even higher temperatures but is more expensive than nichrome. You could get either probably in electronics supply houses. If you do lowfire, maybe up to cone 06 or lower steel will probably be OK. The surface of the steel will oxidise and so get clearly thinner, keep that in mind. Generally your wire and the clay should not be in direct contact because they have different thermal expansion coefficients. Depends how rigid your wire is if it will lead to major damage to your piece. But if you wrap your wire with paper before you put clay around it it is probably OK as long as you don't enclose the entire thing with clay into a hollow space. But it also depends on what exactly you are trying to do, e.g. what kind of clay you are using. Mostly people use wire with clay for making beads. If that's what you are doing you can also look up bead making techniques.

- Q: If I knew which wires went to trim, rpms,engine hours,ect... I could follow them. The engine wiring harnes is stil intact, but I dont know which wire goes to each no matter which end I look at. Like I said wiring is no problem, don't know motors.

- trim is dark brown with white trace. tach is gray. why do you need an hour meter? purple is switched power. black is ground. black with yellow trace is kill. yellow with black trace is choke/primer. yellow with red trace is solenoid/starter. now, let me hold a dollar big man.

- Q: What is the difference between carbon fiber and wire heating?

- The biggest characteristic of carbon fiber heating is that the electromagnetic radiation is very small. It is smaller than the electromagnetic shielding of the wire, and is harmless to the human body

Send your message to us

Hardware Steel Wire in Electro and Hot -Dipped Galvanized

- Loading Port:

- Yantai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords