Grade Z40-Z280 Galvanized Steel Sheet Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Grade | DX51D, SGCC, CGCC |

Thickness | 0.15mm-1.5mm |

Width | 600mm-1500mm(914/1219/1250 are available) |

Standard | JIS G3312, ASTM,GB/T1275 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Length | As per requests |

Zinc Coating | 40g-275g/m2 |

Lacquer Coated | 20-25 microns/5-15 microns |

Coil ID | 508mm/610mm |

Coil Weight | normally 3-10mt or as your requirement |

Supply ability | 200,000Mt/year (MOQ:25Mt) |

Color | RAL No. |

Price terms | FOB,CFR,CIF |

Payment terms | L/C,T/T |

Deliver time | 30days after received deposit or L/C |

Packing | Standard exporting package |

steel strip Water proof paper, metal covers, | |

Application | Corrugated roofing,outside building, |

boating building,car producing | |

household appliance | |

Main market | Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and Regions |

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Thickness | Width | Length of plate | Inner diameter of coil |

0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass: | |||

Available Coated Mass(g/m^2) | Base plate | Available Coated Mass(g/m^2) | |

60,80, 100, 120, 160, 180 | Galvanized Steel | 60,80, 100, 120, 160, 180 | |

50, 70, 150 | Galvalume Steel | 50, 70, 150 |

Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface |

|

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coatin | Primer coating + Finish back coating | 2/2 | |

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

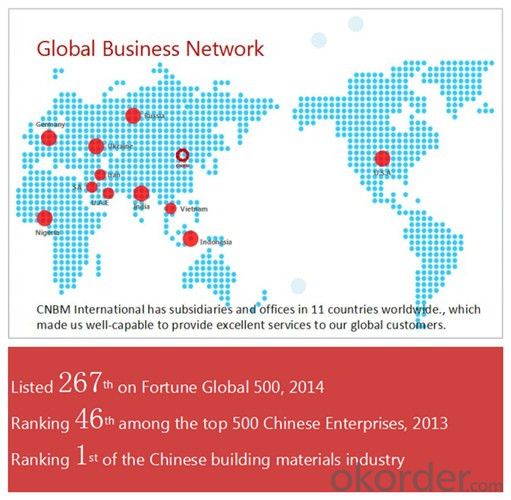

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

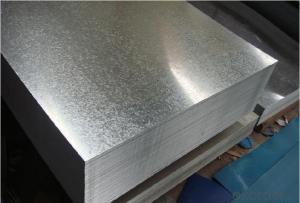

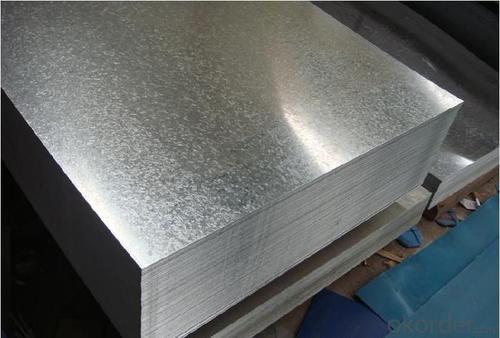

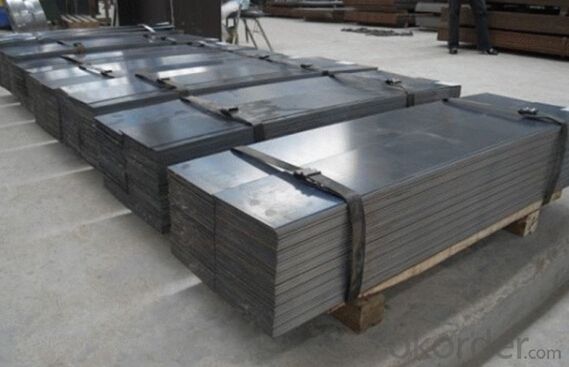

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the requirements for special steel used in low-temperature applications?

- The requirements for special steel used in low-temperature applications include high toughness, excellent resistance to brittle fracture, and good ductility at low temperatures. It should have a low carbon content to prevent embrittlement, along with specific alloying elements like nickel, manganese, and chromium to enhance its low-temperature properties. Additionally, the steel should have good weldability and corrosion resistance to withstand the harsh conditions often encountered in low-temperature environments.

- Q: How is special steel used in the manufacturing of machinery?

- Special steel is an essential component in the manufacturing of machinery due to its unique properties that make it highly suitable for this purpose. Special steel refers to a category of steel alloys that have been specifically designed and developed to possess exceptional strength, durability, and resistance to wear and tear. In the manufacturing of machinery, special steel is commonly used in various applications. One of the primary uses is in the production of machine components that require high strength and toughness, such as gears, shafts, bearings, and fasteners. These components are subjected to heavy loads, high temperatures, and harsh operating conditions, and therefore, they need to withstand these stresses without failure or deformation. Special steel provides the necessary strength and toughness to ensure the longevity and reliability of these machine parts. Additionally, special steel is also utilized in the manufacturing of cutting tools and dies. Cutting tools, such as drills, milling cutters, and lathe tools, need to have excellent hardness and wear resistance to withstand the forces and abrasion encountered during the machining process. Dies, on the other hand, are used to shape or form materials, and they require high strength and hardness to withstand the repetitive pressure and deformation. Special steel provides the necessary properties to enhance the performance and lifespan of these cutting tools and dies. Furthermore, special steel is often utilized in the construction of machine frames and structural components. The strength and rigidity of special steel make it ideal for supporting heavy loads and maintaining the overall stability of the machinery. By using special steel in the construction of machine frames, manufacturers can ensure the structural integrity and durability of the machinery, which is crucial for safe and efficient operation. Overall, special steel plays a vital role in the manufacturing of machinery by providing the strength, durability, and wear resistance necessary for critical machine components, cutting tools, and structural elements. Its unique properties make it indispensable in the production of high-performance machinery that can withstand the demanding conditions of various industries.

- Q: How does special steel contribute to the transportation sector?

- The transportation sector relies heavily on special steel due to the numerous benefits it offers. Special steel plays a pivotal role in improving the efficiency, safety, and overall performance of vehicles. One primary advantage is its high strength-to-weight ratio, which allows manufacturers to reduce vehicle weight without compromising structural integrity. As a result, fuel efficiency improves, emissions decrease, and operating costs are lowered. Furthermore, special steel exhibits exceptional resistance to corrosion, making it especially advantageous in areas with severe weather conditions or exposure to saltwater, such as coastal regions or winter roadways where salt is used for ice melting. This corrosion resistance helps extend the lifespan of transportation infrastructure, such as bridges, tunnels, and railways, thus minimizing maintenance and replacement expenses. Another important aspect is the outstanding impact resistance of special steel. It can withstand heavy impacts and collisions, making it ideal for constructing vehicle frames, body panels, and safety components. This enhances passenger safety and reduces the likelihood of severe injuries during accidents. Special steel also plays a crucial role in producing high-performance engines and powertrains. Steel alloys with specific characteristics, such as high temperature and wear resistance, are utilized in manufacturing critical engine components like pistons, crankshafts, and camshafts. This ensures long-lasting and efficient engine performance, resulting in improved reliability and reduced downtime. Moreover, special steel contributes to advancements in electric and hybrid vehicles. Certain steel alloys possess unique properties that enable the development of lightweight battery packs, electric motor components, and charging infrastructure. These advancements facilitate the shift towards greener transportation options and help decrease the environmental impact of the sector. Overall, special steel has a profound influence on the transportation sector by providing lightweight, durable, corrosion-resistant, and impact-resistant materials. It not only enhances the performance and safety of vehicles but also contributes to the establishment of sustainable and efficient transportation systems.

- Q: How does electrical steel minimize energy losses in electrical devices?

- Electrical steel minimizes energy losses in electrical devices due to its unique magnetic properties. It is specifically designed to have low electrical resistance and high magnetic permeability, allowing it to efficiently conduct and transfer electrical energy while reducing heat generation and energy wastage. This enables electrical devices, such as transformers and motors, to operate more efficiently and effectively, thus minimizing energy losses.

- Q: What are the challenges in welding special steel?

- One of the main challenges in welding special steel is its high carbon content, which can result in increased hardness and brittleness. This requires careful control of the welding process, including preheating and post-weld heat treatment, to prevent cracking and ensure proper weld strength. Additionally, special steels often have alloying elements that can influence the weldability, such as chromium, nickel, or molybdenum, requiring specific filler materials and welding techniques. Overall, the challenges in welding special steel lie in achieving a strong and defect-free weld while maintaining the desired mechanical properties of the steel.

- Q: How does special steel contribute to the energy sector?

- The energy sector heavily relies on special steel, which plays a vital role in improving efficiency, reliability, and safety. Firstly, special steel is essential for constructing pipelines and storage tanks in the oil and gas industry. These components must withstand high pressures, extreme temperatures, and corrosive surroundings, and special steel provides the necessary strength and resistance to ensure their integrity and prevent any leakage. Additionally, special steel is utilized in power generation plants to manufacture turbine blades and other crucial parts. These plants require materials that can endure the high temperatures and pressures generated by fossil fuel combustion or nuclear energy use. Special steel's heat-resistant properties make it the perfect choice for these applications, enhancing the overall efficiency and longevity of power plants. Furthermore, special steel is vital for producing wind turbines, which are rapidly becoming a significant source of renewable energy. The blades, tower structures, and gearboxes of wind turbines undergo significant stress and strain, and special steel provides the strength and durability needed to withstand these conditions. By incorporating special steel, wind turbines can operate reliably and efficiently, contributing to the growth of clean energy. Moreover, special steel is indispensable for infrastructure in the energy sector, such as transmission towers and substations. These structures must support heavy loads and endure extreme weather conditions while maintaining electrical conductivity. Special steel's high strength and corrosion resistance make it an ideal material for these applications, ensuring the reliable transmission and distribution of electricity. In summary, special steel is a crucial element in the energy sector, providing the necessary strength, durability, and resistance to extreme conditions. Its use in pipelines, power generation plants, wind turbines, and infrastructure improves the efficiency, reliability, and safety of the energy sector, facilitating the production and distribution of both conventional and renewable energy sources.

- Q: What are the main characteristics of pressure vessel steel?

- Pressure vessel steel is a specific type of steel that is designed and manufactured to withstand high-pressure environments. It possesses several distinct characteristics that make it suitable for such applications. Firstly, pressure vessel steel has excellent strength and toughness properties. It is able to withstand the internal pressure exerted on it without deforming or rupturing, ensuring the safety and integrity of the vessel. This high strength is achieved through careful alloying and heat treatment processes that enhance its mechanical properties. Secondly, pressure vessel steel exhibits good weldability. This is crucial as pressure vessels often require various components to be joined together. The ability to weld the steel without compromising its structural integrity is essential for the fabrication and maintenance of pressure vessels. Additionally, pressure vessel steel is known for its high corrosion resistance. The steel is typically alloyed with elements such as chromium, molybdenum, and nickel, which provide a protective barrier against corrosive substances and environments. This is vital in preventing the degradation of the vessel and ensuring its long-term durability. Furthermore, pressure vessel steel is characterized by its ability to withstand a wide range of temperatures. It can maintain its strength and toughness even in extreme temperature conditions, making it suitable for applications where the vessel is subjected to high or low temperatures. Lastly, pressure vessel steel is subjected to rigorous testing and quality control measures to ensure its reliability and safety. It must meet specific standards and certifications, such as those established by organizations like the American Society of Mechanical Engineers (ASME), to be deemed suitable for pressure vessel applications. Overall, the main characteristics of pressure vessel steel include high strength and toughness, good weldability, corrosion resistance, temperature resistance, and adherence to strict quality standards. These properties make it an ideal material for the construction of pressure vessels, which are used in various industries such as oil and gas, chemical processing, and power generation.

- Q: How does special steel perform in cutting applications?

- The outstanding performance of special steel in cutting applications is highly regarded. Its unique composition and properties give it superior strength, hardness, and wear resistance compared to regular steel. These characteristics make it highly effective in handling the intense forces and pressures involved in cutting processes. Special steel is renowned for its ability to maintain its shape and sharpness even in extreme conditions. It possesses a high level of toughness, enabling it to withstand repeated impact and resist deformation or breakage. This durability allows it to retain its cutting edge for a longer period, resulting in extended tool life and reduced downtime for blade sharpening or replacement. Moreover, special steel's hardness enables it to effectively cut through tough and abrasive materials such as metals, alloys, and composites. It can endure the heat generated during cutting, preventing the blade from becoming dull or losing its cutting ability. This heat resistance also minimizes the risk of thermal damage to the workpiece, ensuring precise and clean cuts. Furthermore, special steel offers excellent corrosion resistance in addition to its mechanical properties. This is particularly advantageous in cutting applications that involve exposure to moisture, chemicals, or corrosive environments. The corrosion resistance guarantees that cutting tools made from special steel maintain their performance and longevity, even in challenging conditions. In conclusion, special steel demonstrates exceptional performance in cutting applications due to its superior strength, hardness, wear resistance, and corrosion resistance. Its ability to maintain a sharp cutting edge, endure high pressures and temperatures, and resist corrosion makes it a preferred choice in various industries, including manufacturing, construction, automotive, and aerospace.

- Q: How does special steel contribute to the manufacturing of defense equipment?

- Special steel plays a crucial role in the manufacturing of defense equipment due to its exceptional properties. It provides enhanced strength, durability, and resistance to extreme conditions, making it ideal for critical components such as armor plates, missile casings, or aircraft parts. Special steel's ability to withstand high temperatures, impacts, and corrosion ensures the reliability and longevity of defense equipment, ultimately enhancing the safety and effectiveness of military operations.

- Q: What are the challenges in surface treating special steel?

- Surface treating special steel can present a range of challenges due to the unique properties and composition of the material. Some of the main challenges include: 1. Hardness: Special steels often have a high level of hardness, making it difficult to achieve effective surface treatment. Traditional methods like heat treatment or chemical processes may not be sufficient to alter the surface properties without affecting the core strength. 2. Surface contamination: Special steels are susceptible to contamination during the surface treatment process. Even small traces of impurities or foreign materials can compromise the integrity of the treated surface. It is crucial to have a controlled environment and use clean equipment to minimize contamination risks. 3. Complex alloy composition: Special steels are typically alloyed with various elements to enhance their specific characteristics, such as corrosion resistance or high temperature stability. This complex composition can make it challenging to find suitable surface treatment techniques that can effectively modify the surface properties without negatively impacting the alloy's overall performance. 4. Adhesion and coating uniformity: Achieving good adhesion and coating uniformity on special steel surfaces can be problematic. The surface characteristics and microstructure of special steels can make it challenging for coatings or treatments to adhere properly and evenly. Special attention must be given to surface preparation and the selection of appropriate primers or coatings to ensure good adhesion and uniformity. 5. Heat sensitivity: Some special steels may be sensitive to heat during surface treatment processes. Excessive heat exposure can alter the material's properties, leading to structural changes or even deformation. Careful temperature control and suitable cooling methods need to be employed to prevent any undesirable effects on the steel during the surface treatment process. 6. Cost: Surface treating special steel can be a costly process due to the specialized equipment, materials, and expertise required. Additionally, the challenges mentioned above can increase the complexity and time required for surface treatment, leading to higher costs. It is essential to consider these factors when planning and budgeting for surface treatment on special steel components.

Send your message to us

Grade Z40-Z280 Galvanized Steel Sheet Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords