Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

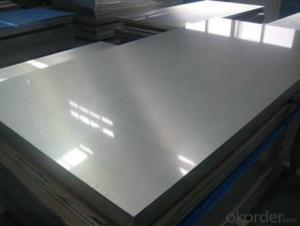

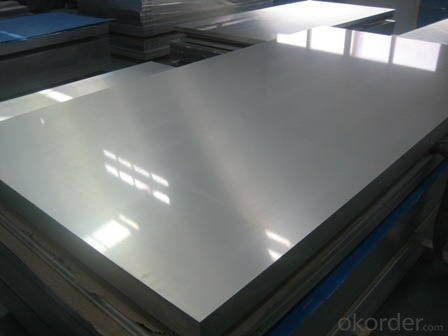

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices

| goods | Hot dip galvanized steel coil and sheet |

| Technical Standard: | JIS 3302 / ASTM A653 / EN10143/EN10327 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.17-1.6mm (0.25-0.45mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-120g/m2 |

| Surface treatment | chromed / skin pass/ oiled /un oiled /slightly oiled/ dry |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| MOQ | 5 Tons |

| Package: | Properly packed for ocean freight exportation in 20''containers |

| Price terms | FOB,CFR,CIF,CPT.CNF,CIP |

| Payment terms | 30%TT in advance+70% TT or irrevocable 70%L/C at sight |

| delivery time | 7days after receipt of 30% TT |

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices

| Material | Tensile test | ||||||

| Rel | Rm (MPa) | Elongation | |||||

| (MPa) | 1.8~<2.0< span=""> | 2.0~<2.5< span=""> | 2.5~<3.2< span=""> | 3.2~<4.0< span=""> | ≥4.0 | ||

| SPHC | ≥270 | ≥29 | ≥30 | ≥31 | ≥32 | ≥32 | |

| SPHD | ≥270 | ≥32 | ≥33 | ≥35 | ≥37 | ≥39 | |

| SPHE | ≥270 | ≥33 | ≥35 | ≥37 | ≥39 | ≥41 | |

| SS330 | ≥205 | 330~430 | ≥26 | ||||

| SS400 | ≥245 | 400~510 | ≥24 | ||||

| SAPH370 | ≥370 | ≥255 | ≥32 | ||||

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

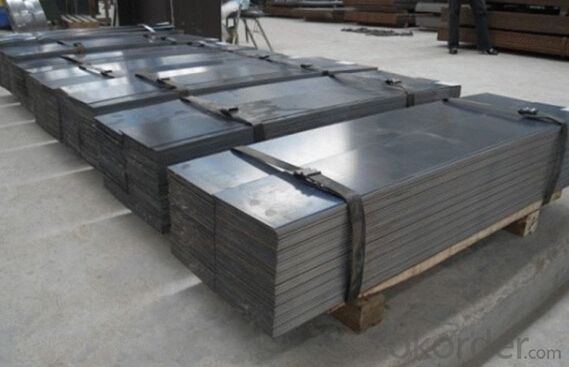

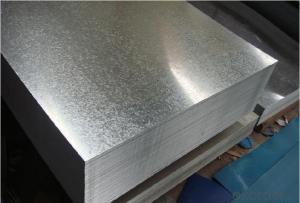

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the main applications of special steel in the energy storage industry?

- Special steel is extensively used in the energy storage industry for various applications. It is primarily employed in the manufacturing of storage tanks and containers, ensuring the safe storage and transport of energy sources such as liquefied natural gas (LNG) or compressed hydrogen. Special steel is also utilized in the construction of battery casings and components, providing durability and protection for energy storage systems. Additionally, special steel is crucial in the fabrication of critical infrastructure, such as pipelines and transmission towers, which play a vital role in the efficient distribution of energy. Overall, special steel serves as a fundamental material in the energy storage industry, enabling the reliable and secure storage, transportation, and utilization of various energy sources.

- Q: What are the different powder coating techniques used for special steel?

- Some of the different powder coating techniques used for special steel include electrostatic spray deposition, fluidized bed coating, and flame spray coating.

- Q: How is special steel used in the packaging supply chain?

- Special steel is used in the packaging supply chain for various purposes. It is used to manufacture durable and strong packaging equipment such as steel drums, containers, and pallets. These steel products ensure the safe transportation and storage of goods, especially heavy or hazardous materials. Additionally, special steel is used in the production of cutting tools, blades, and molds that are essential for packaging processes. Overall, special steel plays a crucial role in ensuring the efficiency, reliability, and safety of the packaging supply chain.

- Q: What are the different special steel products available in the market?

- There are a wide variety of special steel products available in the market, each designed to meet specific industrial needs. Some of the common special steel products include: 1. Stainless Steel: This is a corrosion-resistant steel alloy that contains a minimum of 10.5% chromium. It is widely used in applications that require high resistance to corrosion, such as kitchen utensils, medical instruments, and chemical processing equipment. 2. Tool Steel: Tool steel is a type of carbon and alloy steel that is specifically designed to be used in the manufacturing of tools. It is known for its high hardness, resistance to abrasion, and ability to retain sharp edges. Tool steel is commonly used in the production of cutting tools, dies, and molds. 3. Alloy Steel: Alloy steel is a steel that has been alloyed with other elements, such as manganese, silicon, nickel, or chromium, to enhance its mechanical properties. It offers improved strength, toughness, and wear resistance compared to carbon steel. Alloy steel is used in various applications, including automotive components, construction equipment, and machinery parts. 4. High-Speed Steel: High-speed steel is a type of tool steel that is capable of cutting at high speeds without losing its hardness or ability to retain sharp edges. It is commonly used in the production of drills, milling cutters, and saw blades. 5. Spring Steel: Spring steel is a low-alloy, medium or high carbon steel that is known for its ability to retain its shape and elasticity even under high stress or repeated loadings. It is widely used in the manufacturing of springs, suspension systems, and shock absorbers. 6. Electrical Steel: Electrical steel, also known as silicon steel, is a specialized steel alloy that exhibits low electrical losses and high magnetic permeability. It is used in the production of electrical transformers, motors, and generators. 7. Heat-Resistant Steel: Heat-resistant steel is designed to withstand high temperatures without losing its mechanical properties. It is commonly used in applications such as furnaces, heat exchangers, and gas turbines. These are just a few examples of special steel products available in the market. The choice of steel product depends on the specific requirements of the application, including factors such as corrosion resistance, strength, hardness, and heat resistance.

- Q: What are the future trends in special steel manufacturing?

- The future trends in special steel manufacturing are likely to focus on advancements in technology, sustainability, and the development of new alloys. Firstly, technology will play a significant role in shaping the future of special steel manufacturing. Automation and robotics are expected to be increasingly integrated into the production process, leading to improved efficiency, precision, and reduced labor costs. This will also allow for better quality control and the ability to produce more complex and customized steel products. Secondly, sustainability will be a key focus in special steel manufacturing. As the world becomes more environmentally conscious, companies are seeking ways to reduce their carbon footprint. This includes employing cleaner production methods, such as using renewable energy sources and implementing recycling programs to minimize waste. Additionally, there will likely be a shift towards developing greener alloys with reduced environmental impact. Furthermore, the development of new alloys will be crucial in meeting the evolving needs of various industries. With advancements in material science, special steel manufacturers will be able to create alloys with enhanced properties, such as increased strength, durability, corrosion resistance, and heat resistance. These new alloys will cater to the growing demand for high-performance materials in sectors like aerospace, automotive, energy, and construction. Moreover, the future of special steel manufacturing is also likely to be influenced by the increasing demand for lightweight materials. As industries strive to improve fuel efficiency and reduce emissions, there will be a need for special steel alloys that offer high strength-to-weight ratios. This will drive research and development efforts towards creating lighter yet stronger steel products. In conclusion, the future trends in special steel manufacturing will revolve around technological advancements, sustainability, and the development of new alloys. These trends will shape the industry, bringing about increased automation, cleaner production methods, and the creation of innovative alloys to meet the changing needs of various sectors.

- Q: How is wear-resistant tool steel used in the production of cutting tools?

- Wear-resistant tool steel is used in the production of cutting tools because of its high hardness, toughness, and resistance to wear. This type of steel can withstand the high pressures and temperatures generated during cutting processes, ensuring that the cutting tools maintain their sharpness and durability for extended periods. The wear-resistant tool steel is typically used to make the cutting edges or inserts of tools such as drills, milling cutters, saw blades, and lathe tools. It helps in improving the tool's performance, reducing tool wear, and increasing productivity in various manufacturing industries.

- Q: What are the main factors affecting the heat resistance of special steel?

- The heat resistance of special steel is determined by several key factors, including its alloy composition, microstructure, and heat treatment. The addition of specific elements like chromium, nickel, molybdenum, and tungsten can enhance the steel's ability to withstand high temperatures by forming stable oxide layers on its surface, which protect against oxidation and corrosion. The microstructure of special steel also plays a role in its heat resistance. Factors like grain size, phase distribution, and the presence of precipitates can affect the steel's thermal stability. Fine-grained structures and a homogeneous phase distribution improve resistance to creep, while precipitates like carbides or intermetallic compounds strengthen the steel and prevent thermal softening. Heat treatment processes, such as quenching and tempering, have a significant impact on the heat resistance of special steel. Proper heat treatment optimizes the microstructure and enhances mechanical properties, including resistance to thermal degradation. Controlled quenching, for example, promotes the formation of a martensitic structure, which increases hardness and strength at high temperatures. Other factors that influence heat resistance include impurities, surface conditions, and environmental factors. Impurities like sulfur and phosphorus can reduce resistance to high temperatures by promoting brittle phase formation or oxidation. Surface conditions, such as roughness or cracks, can cause localized heating and accelerated degradation. Environmental factors like corrosive gases or high humidity can also promote oxidation or corrosion. In conclusion, the heat resistance of special steel is affected by alloy composition, microstructure, heat treatment, impurities, surface conditions, and environmental factors. Understanding and optimizing these factors are crucial for developing special steel with superior heat resistance for various industrial applications.

- Q: What are the challenges in heat treatment of special steel alloys?

- The challenges in heat treatment of special steel alloys primarily revolve around achieving the desired mechanical properties while maintaining the material's chemical composition and microstructure. Special steel alloys often contain a complex combination of elements, making it crucial to carefully control the heating and cooling processes to prevent undesirable phase transformations or the formation of unwanted precipitates. Additionally, the high hardenability of some special steel alloys can lead to difficulties in achieving uniform hardness throughout the material. Achieving precise temperature control, as well as managing the time and cooling rates, becomes critical in order to avoid issues such as distortion, cracking, or reduced mechanical strength. Overall, the challenges in heat treating special steel alloys lie in finding the right balance between achieving the desired properties while avoiding any detrimental effects on the material's integrity.

- Q: What are the different mechanical defects in special steel?

- Special steel can be compromised in its overall strength and performance by various mechanical defects. The most common defects are: 1. Inclusions: These are foreign particles or impurities found in the steel, including oxides, sulfides, or other non-metallic materials. Inclusions weaken the steel, reducing its ductility and making it more prone to cracking or failure. 2. Segregation: Uneven distribution of alloying elements within the steel is known as segregation. This can cause variations in hardness, strength, and other mechanical properties throughout the material. Segregation creates localized areas of weakness, increasing the risk of failure under stress. 3. Cracks: Special steel can develop cracks due to factors like improper cooling, excessive heat, or high levels of stress. These cracks significantly reduce the structural integrity of the steel and may spread over time, leading to catastrophic failure. 4. Laminations: Thin layers or sheets of material, called laminations, can form during the manufacturing process. They occur due to improper rolling or forging, or the presence of inclusions. Laminations weaken the steel and cause premature failure under load. 5. Decarburization: Exposure to high temperatures or oxidation causes decarburization, which is the loss of carbon from the steel's surface. This results in a layer of softer, lower carbon steel on the surface, reducing the material's overall hardness and strength. 6. Grain growth: Over time, the individual crystals within the steel (grains) can grow larger, leading to grain growth. High temperatures, prolonged stress exposure, or improper heat treatment can cause this. Grain growth reduces the steel's strength and toughness, making it more susceptible to deformation or fracture. It is important to understand that the severity of these mechanical defects can vary and is influenced by factors such as the manufacturing process, quality control measures, and the specific composition of the special steel. Regular inspection, testing, and adherence to proper handling and processing techniques are crucial in minimizing these defects and ensuring the desired mechanical properties of special steel.

- Q: What are the requirements for special steel used in wind turbines?

- The requirements for special steel used in wind turbines typically include high strength and durability, resistance to corrosion and fatigue, excellent weldability, and good magnetic properties. Additionally, the steel should possess good formability and machinability to aid in the manufacturing process of turbine components.

Send your message to us

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords