Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Grade | DX51D, SGCC, CGCC |

Thickness | 0.15mm-1.5mm |

Width | 600mm-1500mm(914/1219/1250 are available) |

Standard | JIS G3312, ASTM,GB/T1275 |

Certificate | ISO9001.ISO14001.OHSAS18001 |

Length | As per requests |

Zinc Coating | 40g-275g/m2 |

Lacquer Coated | 20-25 microns/5-15 microns |

Coil ID | 508mm/610mm |

Coil Weight | normally 3-10mt or as your requirement |

Supply ability | 200,000Mt/year (MOQ:25Mt) |

Color | RAL No. |

Price terms | FOB,CFR,CIF |

Payment terms | L/C,T/T |

Deliver time | 30days after received deposit or L/C |

Packing | Standard exporting package |

steel strip Water proof paper, metal covers, | |

Application | Corrugated roofing,outside building, |

boating building,car producing | |

household appliance | |

Main market | Southeast Asia , the EU, Russia, Ukraine , Latin America and other countries and Regions |

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

Thickness | Width | Length of plate | Inner diameter of coil |

0.18-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass: | |||

Available Coated Mass(g/m^2) | Base plate | Available Coated Mass(g/m^2) | |

60,80, 100, 120, 160, 180 | Galvanized Steel | 60,80, 100, 120, 160, 180 | |

50, 70, 150 | Galvalume Steel | 50, 70, 150 |

Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20±5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface |

|

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coatin | Primer coating + Finish back coating | 2/2 | |

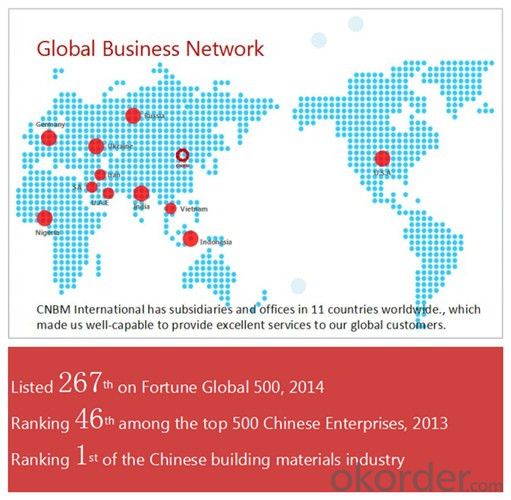

CNBM Introduction of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of PPGI Prepainted Galvanized Steel Roof Sheets in Coils

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

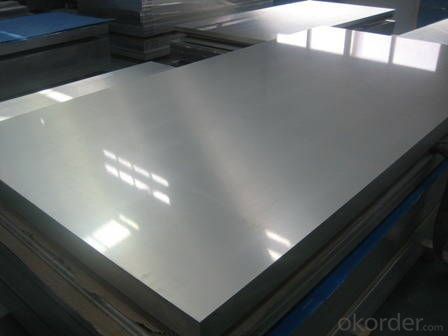

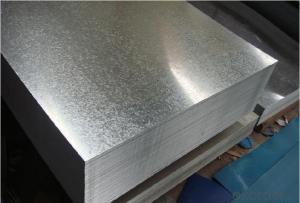

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different case hardening grades of special steel?

- Special steel offers a variety of case hardening grades, each with its own distinct properties and uses. Some of the commonly employed grades are: 1. 8620: This grade is commonly utilized for high-stress applications like gears and shafts. Its remarkable toughness and resistance to wear make it ideal for parts requiring both durability and strength. 2. 9310: Aerospace applications often rely on this grade due to its high strength and resistance to fatigue. It is frequently employed for gears, bearings, and components demanding exceptional toughness and load-carrying capacity. 3. 4340: Known for its hardenability and high strength, this grade is suitable for parts necessitating great tensile strength and impact resistance, such as crankshafts, connecting rods, and gears. 4. 20MnCr5: This grade finds frequent use in the production of gears, camshafts, and components requiring high surface hardness and resistance to wear. It boasts excellent case-hardening properties and good core strength. 5. EN36C (also referred to as 655M13): This grade is commonly employed for axles, shafts, and crankshafts requiring high tensile strength. Its good hardenability and exceptional toughness make it suitable for heavy-duty applications. To ensure the right grade is chosen for a specific project, it is crucial to consider the application requirements, including desired hardness, strength, and wear resistance. Seeking advice from a metallurgist or materials science expert can aid in selecting the appropriate case hardening grade.

- Q: How does special steel perform in high-speed machining operations?

- Special steel is designed with high-speed machining operations in mind, as it possesses unique properties that make it perfect for cutting, drilling, and shaping at high speeds. To begin with, special steel boasts excellent thermal conductivity, enabling it to effectively dissipate heat generated during machining. This is crucial in high-speed operations, as excessive heat can result in tool wear and deformation. By efficiently transferring heat away from the cutting edge, special steel helps prolong tool lifespan and maintain dimensional accuracy. Additionally, special steel exhibits high hardness and strength, enabling it to withstand the intense forces and pressures encountered during high-speed machining. This allows it to retain its shape and integrity, reducing the likelihood of tool breakage or deformation. Furthermore, its strength ensures that the machined parts possess exceptional durability and resistance to wear. Moreover, special steel demonstrates good machinability, making it easy to cut and shape with minimal effort. Its composition and microstructure are optimized for efficient chip formation and removal, ensuring smooth operations and minimizing the risk of chip clogging or tool jamming. Furthermore, special steel often contains alloying elements like chromium, molybdenum, and vanadium, which enhance its resistance to corrosion and wear. This is particularly important in high-speed machining, where the cutting tools and workpiece are in constant contact. The improved corrosion and wear resistance of special steel contribute to longer tool lifespan and improved surface finish. In summary, special steel is engineered specifically to excel in high-speed machining operations. Its thermal conductivity, hardness, strength, machinability, and resistance to corrosion and wear make it the preferred choice for applications that demand fast and precise metal removal.

- Q: How does special steel contribute to the waste management industry?

- Special steel contributes to the waste management industry in various ways. Its exceptional strength, durability, and resistance to corrosion make it ideal for manufacturing equipment used in waste management processes. Special steel is extensively used in the construction of waste sorting systems, recycling machinery, and waste containers, ensuring their longevity and reliability. Additionally, special steel can be recycled itself, reducing the environmental impact of waste management operations and promoting sustainability in the industry.

- Q: What are the common challenges in machining titanium alloys?

- The common challenges in machining titanium alloys include their high chemical reactivity, low thermal conductivity, high cutting forces, and poor chip control. Additionally, titanium alloys tend to work harden, making them prone to tool wear and requiring frequent tool changes. Moreover, their low modulus of elasticity can lead to vibration and chatter during machining operations, affecting surface quality and dimensional accuracy.

- Q: How does special steel contribute to the energy industry?

- Special steel plays a crucial role in the energy industry by providing high-strength, corrosion-resistant materials that are essential for various applications. It is used in the construction of power plants, oil and gas pipelines, and offshore drilling platforms, ensuring the structural integrity and reliability of these critical infrastructure. Special steel also enables the production of more efficient wind turbines and solar panels, enhancing their performance and durability. Additionally, it is utilized in the manufacturing of equipment used in nuclear power plants, where its unique properties ensure safety and long-term operation. Overall, special steel is a vital component in the energy industry, supporting its growth, sustainability, and technological advancements.

- Q: Can special steel be used in the manufacturing of firearms?

- Special steel is unquestionably applicable for firearm production. In truth, it is frequently favored for this purpose owing to its distinct properties that render it apt for enduring high temperatures, pressures, and stress. Firearms necessitate materials that possess strength, durability, and the capability to withstand the immense forces generated during firing. Special steel alloys, such as stainless steel or heat-treated steel, provide these desired traits and are extensively employed in fabricating firearm barrels, receivers, and other crucial constituents. The incorporation of special steel in firearm manufacturing guarantees the dependability, safety, and consistent performance of these weapons in diverse conditions.

- Q: How is maraging steel used in the production of rocket and missile components?

- Maraging steel is utilized in the manufacturing of rocket and missile components due to its exceptional strength, toughness, and resistance to fatigue and stress. Its unique properties make it ideal for critical parts such as pressure vessels, casings, nozzles, and structural elements, where high-performance materials are required to withstand extreme conditions during launch and flight. Maraging steel's ability to maintain its integrity under intense heat, pressure, and vibrations makes it a crucial material for ensuring the reliability and safety of rocket and missile systems.

- Q: How is alloy steel used in the manufacturing of gears and shafts?

- Alloy steel is commonly used in the manufacturing of gears and shafts due to its superior strength, durability, and resistance to wear and tear. The combination of iron with other elements, such as chromium, nickel, or molybdenum, enhances its mechanical properties, making it suitable for heavy-duty applications. Alloy steel gears and shafts can withstand high loads and torque, ensuring smooth operation and prolonged lifespan in various industrial sectors, including automotive, aerospace, and machinery.

- Q: What are the different methods of surface electroplating for special steel?

- There are several methods of surface electroplating for special steel, including electroless plating, electroplating by immersion, barrel plating, and rack plating. Electroless plating is a chemical process that uses a reducing agent to deposit a layer of metal onto the steel surface. Electroplating by immersion involves immersing the steel in an electrolyte bath and applying an electric current to deposit a metal coating. Barrel plating is a method where the steel parts are placed in a rotating barrel along with the plating solution, creating a tumbling action that ensures an even coating. Rack plating involves suspending the steel parts on a rack and immersing them in the plating bath. Each method has its own advantages and is chosen based on the specific requirements and characteristics of the special steel being plated.

- Q: Can special steel be used in the printing industry?

- Yes, special steel can be used in the printing industry. Special steel, such as stainless steel or tool steel, can be utilized in the manufacturing of printing equipment and machinery parts. These types of steel provide excellent strength, durability, and resistance to wear and corrosion, making them suitable for various components used in printing presses, rollers, blades, and other machinery.

Send your message to us

Grade Z40-Z280 Galvanized Steel Sheet Plate with Low Prices low

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords