Galvanized steel sheet Z80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

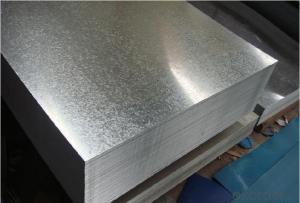

| Grade: | galvanized sheet,DX51D+Z SGCC CSB S280GD+Z S350GD+Z | Standard: | JIS,AISI,ASTM,GB,DIN,EN,JIS,AISI,ASTM,GB,DIN | Length: | 500mm-12000mm,1000~6000mm |

| Thickness: | 0.1mm-100mm | Width: | 600mm-2000mm | Place of Origin: | Jiangsu China (Mainland) |

| Brand Name: | DX51D+Z SGCC CSB S280GD+Z S350GD+Z | Model Number: | galvanized sheet,ASTM A653, ASTMA526-90, JIS G3302, DIN EN10142-92, GB/T 2518 | Type: | Plate |

| Application: | indurstry;electricity construction,home appliances,kitchen appliance, mechanical etc | Certification: | SGS | Surface: | Galvanized |

| Technique: | Cold Rolled | Special Use: | High-strength Steel Plate | Delivery Time: | 3-15 days |

| Delivery Term: | TT or LC |

Packaging & Delivery

| Packaging Detail: | Export standard package :bundled wooden box or be required; The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM We will packing as the factory ,and reach the stander of export . Or as the customer request.In addition,We will make the products with good surface protection |

| Delivery Detail: | within 3--15 days according to the Quantity |

Specifications

China supplier Galvanized Steel Sheet

1:thick:0.25-6mm

2:width:500-1500mm

3:length:any length can be cut

4:on stock

- Q: What type of welding rod is used for steel Q245R and Q235B material?

- Q245R is generally used in boiler or pressure vessel, if it is a large diameter cylinder welding body in wall thickness below 8mm recommended the use of arc welding J507 welding rod, double welding, carbon arc gouging back, to obtain qualifiedQuality; when the wall thickness is thicker, submerged arc welding can be used and welding with H08MnA welding wire and HJ431 flux is used;

- Q: What are the reasons for the steel mesh on both sides of the back pouring belt?

- Increase overall stability. To prevent cracks due to settlement, uneven cement shrinkage, etc., but also to increase the overall firmness. Generally speaking, the stability of the post casting belt is increased.

- Q: Are steel sheets resistant to impact or damage?

- Yes, steel sheets are generally resistant to impact or damage due to their high strength and durability.

- Q: Can steel sheets be used in packaging applications?

- Yes, steel sheets can be used in packaging applications. They are commonly used for packaging heavy or durable items that require strong protection, such as machinery parts or large appliances. Steel sheets offer superior strength and durability, making them suitable for ensuring the safe transportation and storage of various goods.

- Q: Can steel sheets be used in marine applications?

- Yes, steel sheets can be used in marine applications. Steel is a popular material choice for marine applications due to its high strength and durability. It can withstand the harsh conditions of saltwater and is resistant to corrosion. Steel sheets are often used in the construction of ships, offshore platforms, and other marine structures. They provide structural integrity and can be easily fabricated to meet specific design requirements. Additionally, steel sheets can be coated with protective layers, such as anti-corrosion paints or galvanization, to further enhance their resistance to corrosion in saltwater environments. Overall, steel sheets are a reliable and commonly used material in various marine applications.

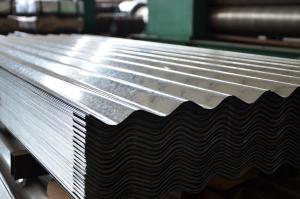

- Q: Can steel sheets be used in the construction industry?

- Yes, steel sheets can be commonly used in the construction industry. Steel sheets are highly versatile and have a wide range of applications in construction. They are used for various purposes, including roofing, wall cladding, flooring, and structural components such as beams, columns, and trusses. Steel sheets are preferred due to their high strength-to-weight ratio, durability, and resistance to corrosion. They can withstand heavy loads and provide stability and structural integrity to buildings. Additionally, steel sheets can be easily fabricated, allowing for customization and efficient construction processes. Overall, steel sheets are a popular choice in the construction industry due to their numerous advantages and suitability for various construction applications.

- Q: What is the electromagnetic steel plate in the generator?

- As the core material, the magnetic conductivity is the core.As for the protection of heat resistant copper wire, the argument is not very good, because under normal circumstances, copper heat than iron core heat greater.

- Q: What is the process of cutting steel sheets?

- The process of cutting steel sheets typically involves using specialized machines or tools, such as plasma cutters, lasers, or shears, to cut through the steel material. The method chosen depends on factors like the thickness of the steel, desired precision, and production volume. These tools apply heat, force, or a combination of both to remove material and create a clean, precise cut in the steel sheets.

- Q: Are steel sheets suitable for interior door panels?

- Yes, steel sheets are suitable for interior door panels. They are sturdy, durable, and provide added security. Additionally, steel sheets can be customized with various finishes and designs to enhance the aesthetic appeal of the door.

- Q: How are steel sheets protected during transportation by air?

- Steel sheets are protected during transportation by air through various measures such as packaging them in protective covers, using cushioning materials like foam or bubble wrap, securing them with straps or bands to prevent movement, and placing them in sturdy crates or pallets to minimize the risk of damage. Additionally, some steel sheets may undergo corrosion-resistant coatings or be stored in climate-controlled containers to protect them from moisture or extreme temperature changes during transit.

Send your message to us

Galvanized steel sheet Z80

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords