galvanized steel sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t. m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Grade: SGH340, DX51D and SGCC (customized)

Surface treatment: passivation, oiling, chromed, unoiled

Spangle types: minimal, zero and large

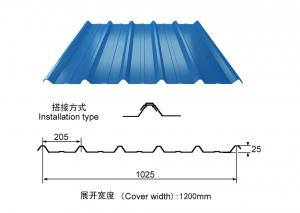

Thickness: 0.37 to 3.5mm

Width: greater than 1,000mm

Inner diameter: 508 to 610mm

Zinc coating: greater than 80g/m2

Applications:

Construction, home appliance, hardware and machinery

Standards:

JIS g3302 1998, ASTM a653 2003, EN10142 1990

EN10327 2004, AS1397 2001, GB2518-2004

Packing: export packing/sea worthy for international delivery

- Q: How to introduce carbon steel plate?

- According to the use of carbon steel can be divided into carbon structural steel, carbon tool steel and free cutting steel structure three, carbon structural steel and steel construction project is divided into two kinds of structural steel and machinery manufacturing; (2) by refining methods can be divided into open hearth steel, steel converter; (3) according to the method of desoxydation can be divided into boiling Teng steel (F), steel (Z) and SEMIKILLED steel (b) and special steel (TZ); (4) according to the carbon content of the steel can be divided into low carbon steel (WC = 0.25%), carbon steel (WC0.25% - 0.6%) and high carbon steel (WC>0.6%); (5) according to the the quality of the steel can be divided into ordinary carbon steel (carbon steel with phosphorus, sulfur, high quality carbon steel (P), low sulfur and high quality steel (P), lower sulfur) and super high quality steel.

- Q: What is the average cost of installing steel sheets?

- The average cost of installing steel sheets can vary depending on various factors such as the size of the project, the type and quality of the steel sheets, the location, and the labor costs. On average, the cost of installing steel sheets can range from $7 to $15 per square foot. However, it is important to note that this is just a rough estimate and actual costs may vary significantly. It is recommended to obtain quotes from multiple contractors or steel suppliers to get a more accurate estimate for a specific project.

- Q: Can steel sheets be used for construction equipment?

- Yes, steel sheets can be used for construction equipment. Steel is a versatile and durable material that offers strength and stability, making it suitable for various construction equipment such as excavators, cranes, bulldozers, and scaffolding. Steel sheets can be formed, welded, and shaped into different components and structures, ensuring the reliability and robustness required in construction applications.

- Q: What is the average price of a steel sheet?

- The average price of a steel sheet can vary depending on several factors such as the size, thickness, quality, and market conditions. Generally, steel sheets can range in price from $500 to $1500 per ton. However, it is important to note that prices can fluctuate due to factors such as global demand, production costs, and trade policies. Additionally, different suppliers may offer different prices, so it is advisable to compare prices from multiple sources before making a purchase.

- Q: Can steel sheets be used in the aerospace industry?

- Yes, steel sheets can be used in the aerospace industry.

- Q: How do steel sheets handle chemical exposure?

- Steel sheets are renowned for their outstanding ability to resist chemical exposure. They exhibit a high level of resistance to corrosion and can endure exposure to a wide array of chemicals, including acids, alkalis, solvents, and other substances that cause corrosion. This exceptional resistance is primarily attributed to the formation of a protective oxide layer, known as patina, on the surface of the steel. This layer acts as a barrier, preventing the chemicals from attacking the steel. Moreover, steel sheets can be further safeguarded by applying various protective coatings, such as galvanization, epoxy coatings, or powder coatings. These coatings provide an extra layer of protection and enhance the steel's resistance to chemical exposure. However, it is important to acknowledge that the resistance of steel sheets to chemical exposure may vary based on the specific type and concentration of the chemicals involved. Highly concentrated or aggressive chemicals may still lead to some degree of corrosion or damage to the steel surface over time. Hence, it is crucial to carefully consider the specific chemical environment and select the appropriate grade of steel and protective coating to ensure optimum resistance to chemical exposure. In summary, steel sheets are a dependable and durable choice for applications that demand resistance to chemical exposure. With careful selection and maintenance, they can effectively withstand diverse chemical environments and deliver long-lasting performance.

- Q: Are the steel sheets suitable for electrical applications?

- Yes, steel sheets are suitable for electrical applications as they have good conductivity and can be easily shaped into desired forms for various electrical components.

- Q: What is the difference between a hot rolled and pickled steel sheet?

- The production of a hot rolled steel sheet involves heating the steel above its recrystallization temperature, typically around 1700°F (926°C), and then rolling it into the desired shape or thickness. This process leads to the formation of a scale or oxide layer on the surface of the steel. In contrast, a pickled steel sheet goes through an additional step known as pickling, which removes the scale or oxide layer formed during the hot rolling process. This step is usually carried out by immersing the steel sheet in an acid bath, such as hydrochloric acid, to dissolve the scale. The main distinction between a hot rolled and pickled steel sheet lies in the surface finish and cleanliness. Due to the presence of scale, a hot rolled steel sheet will have a rougher surface, which may not be visually appealing and might require further processing or finishing. On the other hand, a pickled steel sheet will exhibit a smoother and cleaner surface as a result of the scale removal. Another difference lies in the corrosion resistance of the two types of steel sheets. Hot rolled steel, with its scale, is more prone to corrosion, especially in humid or corrosive environments. Conversely, pickled steel possesses better corrosion resistance due to the elimination of the scale and the subsequent application of a protective coating or treatment. Regarding applications, hot rolled steel sheets are commonly used in structural components, construction materials, and general fabrication where surface finish is not a critical factor. In contrast, pickled steel sheets are often preferred in industries such as automotive, appliances, and manufacturing, where a smooth and clean surface is desired for further processing or finishing. In summary, the difference between a hot rolled and pickled steel sheet lies in the surface finish, cleanliness, and corrosion resistance. While hot rolled steel has a rougher surface due to the presence of scale, pickled steel undergoes an acid bath to remove the scale, resulting in a smoother and cleaner surface. Pickled steel also offers better resistance to corrosion and is preferred in applications where a high-quality surface finish is required.

- Q: Can steel sheets be used for railway applications?

- Indeed, railway applications can make use of steel sheets. The utilization of steel sheets in the construction of railway tracks, bridges, and other infrastructure is widespread. This popularity arises from their remarkable qualities of high strength, durability, and resistance against wear and tear. Steel sheets can be molded into different forms and sizes to cater to the specific demands of railway applications. Moreover, the easy weldability of steel sheets enables the efficient and cost-effective installation and repair of railway components. All in all, the railway industry favors steel sheets due to their exceptional mechanical properties and ability to withstand heavy loads and adverse environmental conditions.

- Q: How do steel sheets handle vibrations?

- Steel sheets are known for their excellent ability to handle vibrations. This is primarily due to their high stiffness and strength properties. When subjected to vibrations, steel sheets tend to absorb and dampen the vibration energy, thus minimizing the transmission of these vibrations to other parts of a structure or system. The inherent properties of steel, such as its high modulus of elasticity and low damping capacity, contribute to its effectiveness in handling vibrations. The high modulus of elasticity allows steel sheets to resist deformation under applied loads, which helps maintain their structural integrity and stability during vibrations. Additionally, the low damping capacity of steel enables it to dissipate the vibrational energy efficiently, preventing excessive oscillations or resonance. Steel sheets are often used in various applications requiring vibration resistance, such as industrial machinery, automotive parts, and building structures. Their robustness and ability to handle vibrations reliably make them a preferred choice in such scenarios. However, it is worth noting that the specific performance of steel sheets in handling vibrations can vary depending on factors such as sheet thickness, material composition, and design considerations.

Send your message to us

galvanized steel sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 8000 m.t. m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords