Galvanized steel sheet Z60

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

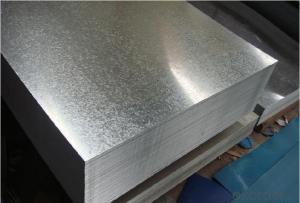

Galvanized Steel Sheet

goods | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143/EN10327 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

Thickness | 0.17-1.6mm (0.25-0.45mm is the most advantage thickness) |

Type of coating: | galvanized |

Zinc coating | Z60-120g/m2 |

Surface treatment | chromed / skin pass/ oiled /un oiled /slightly oiled/ dry |

Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| MOQ | 5 Tons |

Package: | Properly packed for ocean freight exportation in 20''containers |

Price terms | FOB,CFR,CIF,CPT.CNF,CIP |

Payment terms | 30%TT in advance+70% TT or irrevocable 70%L/C at sight |

delivery time | 7days after receipt of 30% TT |

The industrial use

The application field | example illustration |

The electrical appliance industry | Air conditioner,Computer chassis, Plate for refrigerator,Outer shell of washing machine,kitchen fittings, The freezing chamber device |

The building industry | housetop,Lateral wall,doors and windows, gutter,Shutter doors and windows,Wall frame , Ceiling joist,ventiduct |

The agricultural and pastoral | Granary,silo,animal house,trough,flume,Greenhouse trellis,Baking equipment; |

The transport | railroad:The roof of the train,The internal frame of train,The road sign,The inner walls of the train; |

The equipment and structure | radiator,cold roll-formed ,Pedals and rack |

The material and mechanical properties

Material | Tensile test | ||||||

Rel (MPa) | Rm (MPa) | Elongation | |||||

1.8~<2.0 | 2.0~<2.5 | 2.5~<3.2 | 3.2~<4.0 | ≥4.0 | |||

SPHC | ≥270 | ≥29 | ≥30 | ≥31 | ≥32 | ≥32 | |

SPHD | ≥270 | ≥32 | ≥33 | ≥35 | ≥37 | ≥39 | |

SPHE | ≥270 | ≥33 | ≥35 | ≥37 | ≥39 | ≥41 | |

SS330 | ≥205 | 330~430 | ≥26 | ||||

SS400 | ≥245 | 400~510 | ≥24 | ||||

SAPH370 | ≥370 | ≥255 | ≥32 | ||||

- Q: Can steel sheets be used for solar panel manufacturing?

- Yes, steel sheets can be used for solar panel manufacturing.

- Q: What are the different thickness tolerances for steel sheets?

- The thickness tolerances for steel sheets can vary depending on the specific grade, manufacturing process, and industry standards. However, common thickness tolerances for steel sheets range from +/- 0.001 inches to +/- 0.010 inches, with tighter tolerances typically required for more precise applications.

- Q: How do steel sheets perform in fire-rated applications?

- Steel sheets perform exceptionally well in fire-rated applications. Due to their high melting point and excellent heat resistance, they offer superior protection against fire and help to contain its spread. Steel sheets are widely used in fire-rated walls, doors, and ceilings, as they maintain their structural integrity even at extremely high temperatures. Additionally, they contribute to fire safety by limiting the release of toxic gases and smoke, making them a reliable choice for fire protection in various industries and buildings.

- Q: Can steel sheets be painted or powder-coated after installation?

- Yes, steel sheets can be painted or powder-coated after installation. This allows for customization and protection against corrosion or other environmental factors.

- Q: Can steel sheets be used for manufacturing storage cabinets?

- Indeed, storage cabinets can be manufactured using steel sheets. Steel, renowned for its durability and strength, is frequently employed in the construction of cabinets and various storage alternatives. The malleability of steel sheets enables them to be effortlessly fabricated and shaped into the desired cabinet form, offering exceptional support and stability for securely storing weighty items. Furthermore, steel's resistance to corrosion renders it highly suitable for regions with elevated moisture levels or adverse environmental conditions.

- Q: How do steel sheets perform in terms of corrosion resistance?

- Steel sheets generally have good corrosion resistance, especially when they are coated with protective layers such as zinc or alloys. The corrosion resistance of steel sheets depends on the composition and quality of the steel, as well as the environment in which they are utilized. Stainless steel sheets, for example, offer high resistance to corrosion due to the presence of chromium and other alloying elements. These sheets are particularly effective in environments with high humidity, saltwater exposure, or acidic conditions. However, uncoated or low-alloy steel sheets may be prone to rust and corrosion in aggressive environments. Regular maintenance, such as applying protective coatings or using corrosion inhibitors, can enhance the corrosion resistance of steel sheets and prolong their lifespan.

- Q: Are steel sheets resistant to impact or damage?

- Steel sheets are known for their exceptional strength and durability, which makes them highly resistant to impact and damage. Due to their high tensile strength, steel sheets can withstand heavy loads and resist deformation or breakage when subjected to external forces. They are often used in applications where impact resistance is critical, such as in construction, automotive manufacturing, and industrial settings. Additionally, steel sheets can withstand extreme temperatures, corrosion, and environmental factors, which further contributes to their overall resistance to damage. However, it is important to note that the specific resistance to impact or damage may vary depending on the thickness, quality, and composition of the steel sheet.

- Q: Are steel sheets resistant to water or moisture damage?

- Yes, steel sheets are generally resistant to water or moisture damage due to their inherent corrosion-resistant properties.

- Q: Can steel sheets be used in food-grade applications?

- Yes, steel sheets can be used in food-grade applications. Stainless steel sheets are commonly used in various food processing and handling equipment, as they offer excellent resistance to corrosion, durability, and ease of cleaning.

- Q: How do you prevent rust on steel sheets?

- To prevent rust on steel sheets, it is essential to apply a protective coating such as paint or a corrosion-resistant finish. Additionally, keeping the steel sheets dry and avoiding exposure to moisture and humidity can significantly reduce the chances of rust formation. Regular cleaning and maintenance, including the removal of any existing rust, also help in preventing its further spread and maintaining the steel sheets' integrity.

Send your message to us

Galvanized steel sheet Z60

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords