G3312 Grade PPGI Steel Sheets for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

G3312 Grade PPGI Steel Sheets for Roofing

Description of G3312 Grade PPGI Steel Sheets for Roofing

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

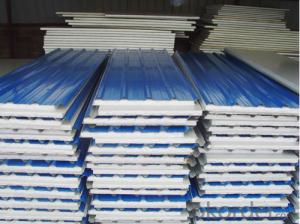

Application of G3312 Grade PPGI Steel Sheets for Roofing

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

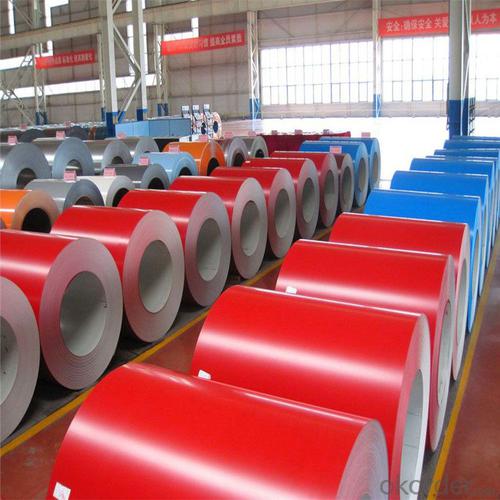

Products Show of G3312 Grade PPGI Steel Sheets for Roofing

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How does special steel contribute to reducing product costs while maintaining quality?

- Special steel contributes to reducing product costs while maintaining quality through various ways. Firstly, special steel offers higher strength and durability, allowing manufacturers to create lighter and more efficient designs. This reduces material usage and transportation costs while maintaining the desired product performance. Additionally, special steel's exceptional corrosion resistance minimizes the need for expensive protective coatings or frequent maintenance, saving on long-term costs. Its superior heat resistance also enables manufacturers to use less energy during production processes, resulting in reduced operational expenses. Furthermore, special steel's unique properties, such as high machinability and formability, enhance manufacturing efficiency. This leads to reduced production time, lower labor costs, and increased overall productivity. Overall, the use of special steel in product manufacturing optimizes cost-efficiency without compromising quality, making it an indispensable material for many industries.

- Q: What is the purpose of annealing in special steel production?

- The aim of annealing in the production of special steel is to enhance the mechanical characteristics and overall quality of the steel. Annealing involves subjecting the steel to a particular temperature and gradually cooling it, typically in a controlled setting. This procedure aids in relieving any internal stresses or strains that might have developed during previous manufacturing processes like rolling or forging. During the annealing process, the microstructure of the steel goes through changes, resulting in a more refined and uniform material. The process allows for the redistribution of atoms, thereby eliminating defects, improving grain structure, and enhancing the steel's toughness, ductility, and machinability. Furthermore, annealing helps in reducing the hardness of the steel, rendering it easier to work with and shape. It also enhances the steel's resistance to cracking and increases its ability to withstand corrosion and other environmental factors. In certain special steel alloys, annealing can also be employed to achieve desired physical properties such as increased hardness or improved magnetic characteristics. Ultimately, the objective of annealing in the production of special steel is to optimize the steel's properties and ensure it meets the specific requirements of its intended application, be it in industries such as automotive, aerospace, or manufacturing.

- Q: What are the common applications of special steel in the manufacturing industry?

- Special steel is commonly used in the manufacturing industry for a variety of applications including the production of tools, machinery parts, automotive components, construction materials, and aerospace equipment. Its high strength, durability, corrosion resistance, and heat resistance make it ideal for demanding environments and critical applications where regular steel may not suffice.

- Q: What are the specific requirements for special steel used in the mining drill bit industry?

- The specific requirements for special steel used in the mining drill bit industry include high strength and hardness to withstand the extreme conditions of drilling, excellent wear resistance to withstand abrasion from rocks and minerals, good toughness to resist breakage and cracking, and high heat resistance to withstand the heat generated during drilling. Additionally, the steel should have good machinability to facilitate the manufacturing process of the drill bits.

- Q: How is maraging steel used in the production of aerospace components?

- Maraging steel is commonly used in the production of aerospace components due to its exceptional strength, toughness, and resistance to corrosion. Its unique properties make it ideal for manufacturing critical parts such as landing gear, engine components, and rocket nozzles. Additionally, maraging steel's high strength-to-weight ratio allows for lighter aircraft structures, leading to improved fuel efficiency and overall performance.

- Q: Can special steel be used in railway applications?

- Yes, special steel can be used in railway applications. Special steel, such as high-strength steel or corrosion-resistant steel, can offer enhanced durability, strength, and resistance to wear and tear in railway components, tracks, and infrastructure. This allows for safer and more efficient railway operations.

- Q: What are the different methods of surface electropolishing for special steel?

- There are several methods of surface electropolishing for special steel, including the use of acid-based or alkaline-based electrolytes, pulse current electropolishing, and reverse current electropolishing. The choice of method depends on factors such as the type of special steel being treated and the desired surface finish.

- Q: How is special steel used in the marine supply chain?

- Special steel is used extensively in the marine supply chain due to its exceptional strength, corrosion resistance, and durability. It is utilized in the construction of various marine components such as ship hulls, propeller shafts, offshore platforms, and marine equipment. Special steel ensures the structural integrity and longevity of these critical marine structures, enabling safe and efficient operations in harsh and corrosive marine environments.

- Q: How does special steel contribute to the mining machinery industry?

- Special steel plays a crucial role in the mining machinery industry by offering exceptional strength, durability, and resistance to wear and corrosion. This type of steel is specifically engineered to withstand the harsh and demanding conditions that are typically encountered in mining operations. In the mining machinery industry, equipment such as drills, excavators, loaders, crushers, and conveyor systems are subjected to extreme stress, heavy loads, and abrasive materials. Special steel components can be found in various parts of these machines, including buckets, tracks, cutting edges, gears, and hydraulic components. The high strength and toughness of special steel ensure that mining machinery can withstand the immense forces and impacts involved in excavation, hauling, and processing of minerals. This durability helps to extend the lifespan of the equipment, reducing the need for frequent replacements and minimizing downtime, which ultimately leads to cost savings for mining companies. Moreover, special steel's resistance to wear and corrosion is vital in the mining industry. The presence of abrasive materials and corrosive substances in the mining environment can lead to rapid deterioration of machinery components. However, special steel alloys are designed to resist wear and corrosion, thereby enhancing the longevity and performance of mining machinery. Additionally, special steel enables mining machinery to operate efficiently and effectively. Its high strength-to-weight ratio allows for the construction of lightweight yet robust equipment, improving mobility and productivity in mining operations. The use of special steel also enables the design of complex components with intricate shapes, ensuring optimal functionality and performance. Overall, special steel is an indispensable material in the mining machinery industry. Its exceptional strength, durability, resistance to wear and corrosion, and ability to enhance efficiency make it a vital component in the design and construction of mining equipment. By incorporating special steel, mining machinery can withstand the harsh conditions and heavy-duty tasks involved in mining operations, ultimately contributing to increased productivity, reduced costs, and improved safety in the industry.

- Q: What are the mechanical properties of special steel?

- Special steel generally refers to high-performance alloys that have enhanced mechanical properties compared to conventional steels. These properties can vary depending on the specific composition and heat treatment of the special steel. However, some common mechanical properties of special steel include high strength, excellent toughness, improved wear resistance, and good corrosion resistance. Special steel is often used in applications requiring exceptional performance, such as in aerospace, automotive, and tooling industries.

Send your message to us

G3312 Grade PPGI Steel Sheets for Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords