PPGI/GI Corrugated Steel Sheet/Metal Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 566 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized steel Coil :

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

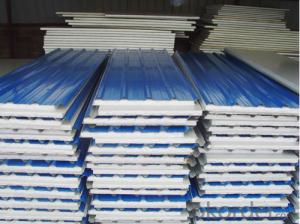

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

| product | corrugated metal roofing sheets |

| Brand | CNBM |

| supply ability | 250,000 tons per year |

| base material | galvanized steel sheet |

| thickness | 0.15-0.6mm |

| width | 600-1250mm |

| quality | spcc,dx51d,sgcc,sgch |

| zinc-coating | 60-180g/m2 |

| technique | cold rolled-hot dipped galvanizing- corrugated |

| tolerance | thickness: +/- 0.02mm |

| width: +/-2mm | |

| feature | lowes sheet metal roofing have excellent performance of decoration, corrosion resisitance etc. |

| package | 1. PVC film 2. Anti-water paper. 3. Metal |

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: How are steel plates used in the fabrication of storage silos?

- Steel plates are used in the fabrication of storage silos to provide strength and stability to the structure. These plates are welded together to form the cylindrical shape of the silo, ensuring it can withstand the weight of the stored materials and any external forces. Additionally, the steel plates are often coated or treated to prevent corrosion, ensuring the longevity and durability of the storage silo.

- Q: How is steel pipe coated for underground gas pipelines?

- Steel pipe for underground gas pipelines is coated using a process called fusion bonded epoxy coating. This involves preheating the pipe, applying an epoxy powder to it, and then heating it again to create a strong bond. This coating provides corrosion protection and helps to ensure the longevity and safety of the pipeline.

- Q: How is steel used in the transportation industry?

- Steel is used extensively in the transportation industry for various applications such as building vehicles, manufacturing railway tracks, constructing bridges, and designing infrastructure. It provides strength, durability, and impact resistance, making it an ideal material for ensuring the safety and reliability of transportation systems.

- Q: How are steel products used in the water treatment industry?

- Steel products are used in the water treatment industry for various purposes such as constructing water treatment plants, pipelines, and storage tanks. Steel's durability and resistance to corrosion make it an ideal material for ensuring the integrity and longevity of these structures. Additionally, steel screens and filters are used to remove impurities and contaminants from water sources, contributing to the overall efficiency and effectiveness of the water treatment process.

- Q: What are the different types of steel products used in the manufacturing of cleaning equipment?

- Some of the different types of steel products used in the manufacturing of cleaning equipment include stainless steel, carbon steel, and galvanized steel. Stainless steel is commonly used due to its corrosion resistance and durability. Carbon steel is often used for its strength and affordability. Galvanized steel, which is coated with a layer of zinc, is used to provide extra protection against rust and corrosion.

- Q: What are the uses of steel wire mesh in filtration?

- Steel wire mesh is commonly used in filtration due to its durability and ability to withstand high pressure and temperature conditions. It is used to separate solids from liquids or gases in various industries such as oil and gas, water treatment, food processing, and pharmaceuticals. The mesh provides a strong and reliable barrier, allowing for efficient filtration and removal of impurities, particles, or contaminants. Additionally, steel wire mesh can be easily cleaned and maintained, making it a cost-effective and practical choice for filtration applications.

- Q: What are the applications of steel mesh in security fencing?

- Steel mesh is commonly used in security fencing applications due to its high strength and durability. It provides a secure barrier that prevents unauthorized entry and acts as a deterrent to potential intruders. Steel mesh also allows for visibility, making it suitable for areas that require constant monitoring. Additionally, its versatility and customizable design make it ideal for various security applications such as protecting commercial properties, residential areas, prisons, airports, and construction sites.

- Q: How are steel products used in the construction of schools and educational institutions?

- Steel products are widely used in the construction of schools and educational institutions due to their durability, strength, and versatility. They are used for various applications such as structural framing, roofing, doors, windows, and partitions. Steel beams and columns provide support and stability to the buildings, ensuring their longevity and resistance to natural disasters. Additionally, steel is often used in the construction of gymnasiums, laboratories, and auditoriums due to its ability to span large distances without the need for additional support, allowing for more open and flexible spaces. Overall, steel products play a crucial role in creating safe, efficient, and aesthetically pleasing educational facilities.

- Q: What are the common types of steel products used in the chemical industry?

- Some common types of steel products used in the chemical industry include stainless steel pipes, tanks, and vessels, as well as steel valves and fittings. These steel products are chosen for their corrosion resistance properties, as they need to withstand harsh chemicals and environments.

- Q: How is steel tubing manufactured?

- Steel tubing is manufactured through a process called tube making, which involves several steps. Initially, a solid steel billet is heated and pierced to form a hollow tube. This tube is then elongated and reduced in diameter using a series of rollers, resulting in a thin-walled tube. Further processing, such as straightening, cutting, and bending, may be done to achieve the desired shape and dimensions. The final product is then subjected to various finishing treatments, including heat treatment, coating, and inspection, to ensure its quality and durability.

Send your message to us

PPGI/GI Corrugated Steel Sheet/Metal Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 566 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords