Construction Roof Boarding Steel Sheet /PPGL Steel roofing Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Construction Roof Boarding Steel Sheet /PPGL Steel roofing Sheets /PPGI

1. Detailed Specifications:

| Product | Construction Roof Boarding Steel Sheet /PPGL Steel roofing Sheets /PPGI |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application of Construction Roof Boarding Steel Sheet /PPGL Steel roofing Sheets /PPGI

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

3. Construction Roof Boarding Steel Sheet /PPGL Steel roofing Sheets /PPGI Image:

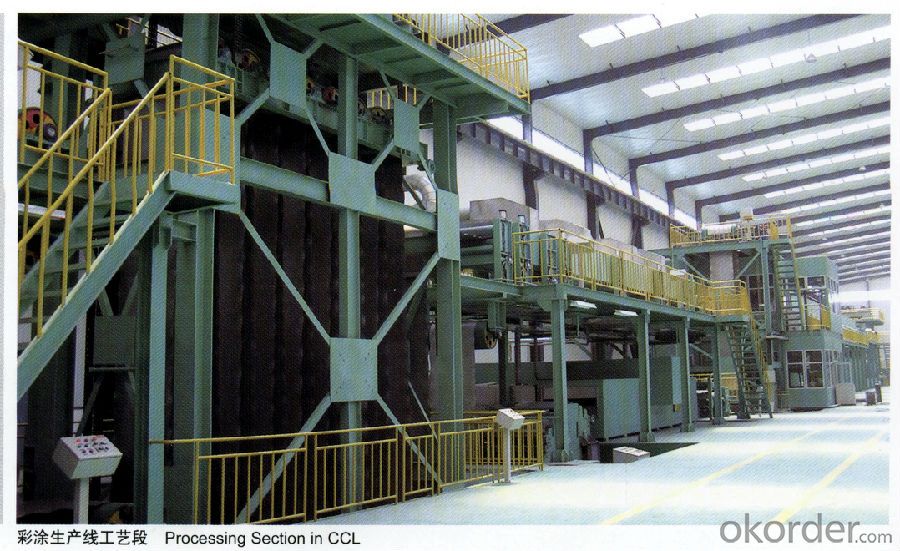

production Line:

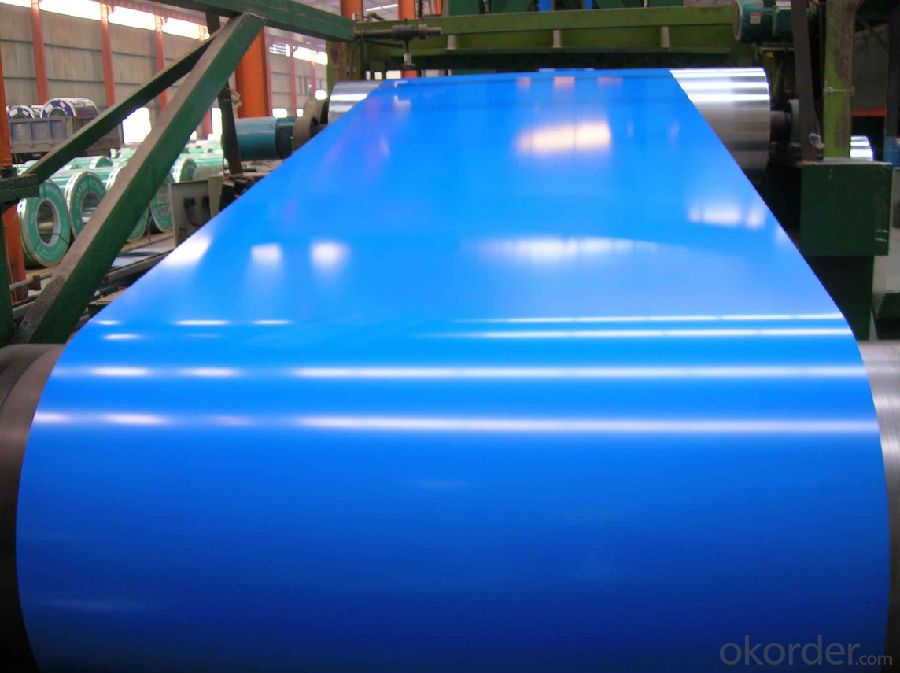

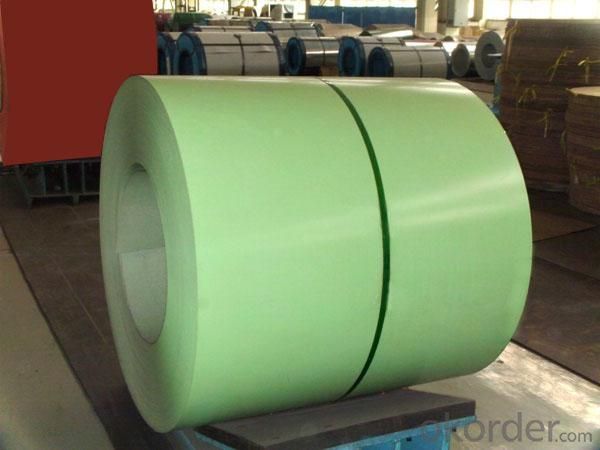

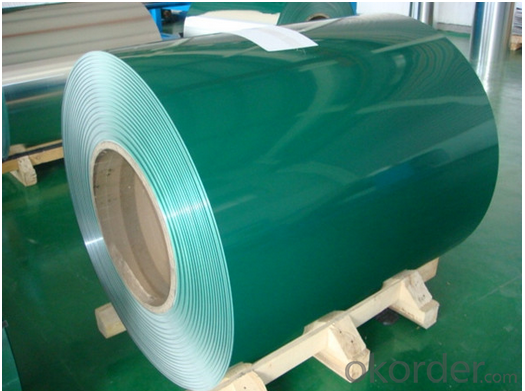

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How are steel coils used in the manufacturing of tools and equipment?

- Steel coils are used in the manufacturing of tools and equipment as they are typically shaped and cut into various components such as blades, springs, and handles. These coils provide the necessary strength and durability required for the tools and equipment to withstand heavy usage and perform effectively.

- Q: What are the environmental considerations when using steel coils?

- Some of the key environmental considerations when using steel coils include the production process, energy consumption, and the potential for waste generation. Steel production is resource-intensive and can result in high greenhouse gas emissions, contributing to climate change. Energy consumption during manufacturing and transportation should be minimized to reduce carbon footprints. Additionally, proper waste management and recycling practices should be implemented to minimize the environmental impact of steel coil usage.

- Q: steel structure

- Disadvantages Of Steel

- Q: What are the dimensions of steel coils used in the building materials industry?

- The dimensions of steel coils used in the building materials industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry typically range from 0.5mm to 3mm in thickness and 600mm to 1500mm in width. The length of the coil can vary depending on the manufacturer and customer specifications. It is also important to note that the weight of the coil can vary, with typical weights ranging from a few hundred kilograms to several tonnes, depending on the size and thickness of the coil. Ultimately, the dimensions of steel coils in the building materials industry are determined by the specific needs and specifications of the construction projects they are intended for.

- Q: I like steel strings but don't want to get a new guitar. Is that my only option?

- Don't EVER put steel strings on a nylon stringed guitar. Steel strings have many times more tension than nylon strings. The bodies on nylon stringed guitars are braced lighter than their steel stringed cousins. If you put steel strings on a guitar designed for nylon, they will belly the top up as well as warp the neck. Since they're attached differently, you'd (luckily) have a hard time even getting steel strings to fit. Enjoy your nylon string guitar for what it is, and if you want to play steel strings, buy a guitar designed for them.

- Q: How are steel coils used in the production of electrical switches?

- Steel coils are used in the production of electrical switches as they serve as a crucial component in the electromagnet that enables the switch to function. The magnetic properties of the steel coils allow for the creation of a strong magnetic field when an electric current passes through them, which in turn allows the switch to be activated or deactivated, controlling the flow of electricity.

- Q: I just want regular steel, not stainless steel.

- Iron is the primary ingredient in steel. All Steel is an alloy by definition. Stainless steels are alloys that resist corrosion. There are dozens of alloys of steel. Many stainless steels are not magnetic. If a magnet won't stick to it it is very likely to be a stainless steel but that is not true for all stainless steels. You really do need to be more specific as to what you want and why. There are too many to chose from.

- Q: I need to know a name of any site which provides information on Steel structures??

- www.okorder /

- Q: How long does the coating on steel coils last?

- The longevity of the coating on steel coils can vary depending on a variety of factors including the type of coating, environmental conditions, and usage. However, with proper maintenance and protection, a well-applied coating can typically last anywhere from 10 to 30 years.

- Q: What are the common methods of welding steel coils?

- The common methods of welding steel coils include arc welding, resistance welding, and laser welding.

Send your message to us

Construction Roof Boarding Steel Sheet /PPGL Steel roofing Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords