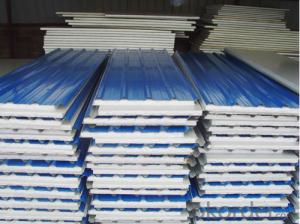

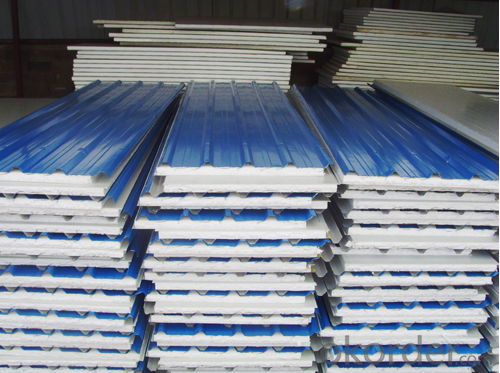

PPGI/0.4mm-0.5mm Pre-Painted Galvanized Steel Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prepainted galvanized steel coil, PPGI, PPGL, Prepainted galvalume/aluzincsteel, Color Coated Galvalume Steel Coil, Prepainted Galvalume Steel Coils, RAL color, 0.15-1.5mm, SGCC, CGCC, CGLC, DX51D, TDC51D, ASTM A653, CS TYPE, S280GO, S350GD, G550, JIS G3312, EN 10169 JIS G3322, ASTM A755/755M, comercial and structual quality

Specifications of Pre Painted Galvanized Steel Coil:

1) Capacity: More than 20, 000 tons per month for PPGI coil product manufacture

2) Standard: JIS G3302, JIS G3312, ASTM A653M/A924M 1998

3) Grade: SGCC CGCC, DX51D, TDC51D, ASTM A653 CS TYPE, S280GD, S350GD, G550

4) Thickness: 0.15mm-1.5mm

5) Zinc coating weight: Z60-275G/M2, G30-G90

Zinc coating: Z60, Z80, Z100, Z120, Z180, Z275, G30, G60, G90

Alu-zinc coating: AZ60, AZ80, AZ100, AZ120, AZ180, G30, G60, G90

6) Width: 600mm-1250mm, 914mm, 1000mm, 1200mm, 1219mm, 1220mm, 1250mm or according to the customer's request

7) Coil ID: 508mm-610mm

8) Coil Weight: 3-6mt, or according to the customer's request

9) Color: RAL, or customer sample color

RAL9016, RAL9002, RAL5015, RAL5002, RAL3000, RAL3020, RAL3009, RAL6005, RAL8017 etc.

10) Color coating type: PE, PVDF, SMP, HDP, etc.

Regular Polyester, Silicon Modified Polyester, Polyvinylidene Floride, PVDF, Super Low Gloss Polyester

11) Surface protection: PVC film protected according to customer requested

12) Min trial order: 25 tons for 1X20' per delivery

PPGI Manufacture

ThicknessWidth LengthColor Coating type

0.2mm-1.5mm600mm-1250mmAs your requestRALPE, PVDF, SMP, HDP, etc.

Coating Chief Feature

ItemThicknessTypeFeature

Laminated film50μ MPolyethyleneProtecting from scratchs and contamination

(option)

Top coat20μ MPolyester FluorineChemical resistance and formability

Primer coat5μ MPolyesterWorkability, corrosion resistance and adhesion to the primer coating

Chemical treatment1μ MChromateGood adhesion and corrosion resistance

Substrate0.2mm-1.2mmGI. GL, ALGI. GL, AL

Back coat5± 2μ MEpoxyCorrosion resistance and adhesion to the substrate

Characteristics:

20 years outdoor liability approved, Corrosion protection, Long life-time for coated color

APPLICATION:

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards

Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

World wide customer satisfaction:

More than 50 worldwide customers none-risky experiences approved.

Yogic has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc...

Classified symbol | Yield Point Minimum N/mm2 | Tensile Strength Minimum | Elongation Minimum % | Application | ||||

N/mm2 | Nominal Thickness mm (t) | |||||||

JIS | CNBM | 0.25≤t<0.4< td=""> | 0.4≤t<0.6< td=""> | 0.6≤t<1.0< td=""> | 1.0≤t<1.6< td=""> | |||

G3312 | specification | |||||||

CGCC | CGCC | -205 | -270 | -20 | -21 | -24 | -24 | Commercial |

CGCD | CGCD | --- | 270 | --- | 27 | 31 | 32 | Drawing |

--- | CG340 | 245 | 340 | 20 | 20 | 20 | 20 | Structural |

CGC400 | CG400 | 295 | 400 | 16 | 17 | 18 | 18 | Structural |

CGC440 | CG440 | 335 | 440 | 14 | 15 | 16 | 18 | Structural |

CGC490 | CG490 | 365 | 490 | 12 | 13 | 14 | 16 | Structural |

CGC570 | CG570 | 560 | 570 | --- | --- | --- | --- | Structural |

ASTM Designation | Yield Point Minimum | Tensile Strength Minimum | Elongation Minimum % | Application | Q/BQB 445-2004(China standard) | ASM A653/A653M | JISG 3312 | |

ksi(MPa) | ksi(MPa) | TDC51D+Z | (CS TYPE A+Z) | CGCC | ||||

A653(M)-99 CS TYPE A,B,C | --- | --- | --- | Commercial | TDC52D+Z | CGCD | ||

A653(M)-99 FS | --- | --- | --- | Lock Forming | TS250GD+Z | (G250+Z) | - | |

A653(M)-99 DS | --- | --- | --- | Drawing | TS300GS+Z | (G300+Z) | CGC 400 | |

A653(M)-99 SS Grade33(230) | 33(230) | 45(310) | 20 | Structural | TS350GD+Z | (G350+Z) | CGC490 | |

A653(M)-99 SS Grade37(255) | 37(255) | 52(360) | 18 | Structural | TS550GD+Z | (G550+Z) | CGC570 | |

A653(M)-99 SS Grade40(275) | 40(275) | 55(380) | 16 | Structural | ||||

A653(M)-99 SS Grade50(345) | 50(345) | 65(450) | 12 | Structural | ||||

A653(M)-99 SS Grade80(550) | 80(550) | 82(570) | --- | Structural | ||||

FAQ

1. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: I don't know why but I'm having a VERY difficult time finding the melting point of 1008 steel.

- 1. okorder 2. Input (melting point 1008 steel) as the search string 3. Check the links; the third one showed the answer in an MSDS

- Q: im playing fallout 3 on ps3 and im at project purity. i keep dying and i heard about broken steel how or what is that plz help me out thnx.

- There is no way to survive that bit, you always die. That's why you save just before you do that quest, leave, do EVERYTHING ELSE there is to do, and then when you're finally sick of the game do it. Anyway Broken Steel is a DLC pack for Fallout 3 that makes you survive that. It ups the level cap, continues the game, adds new missions and weapons and adds tougher monsters to fight. It's one of the best DLC for the game IMO. I'm not sure if it's released yet for the PS3 version, but it will be out soon if it isn't. Check the Playstation store from the PS3 main menu.

- Q: Can steel coils be stored in a corrosive environment?

- No, steel coils should not be stored in a corrosive environment as it can cause damage and corrosion to the coils, reducing their quality and durability over time.

- Q: so i just bought a stainless steel bracelet.......and recently found out that stainless steel isnt actually stainless..........will turpentine ruin it

- real s/steel is nickel and chrome, however manufacturers of kitchenware, e.g s/teel cutlery use the cheaper version of nickel chrome and iron, that is why some s/steel products rust, so if you want to test any products carry asmall magnet and test the article

- Q: How are steel coils inspected for coil weight accuracy after processing?

- Steel coils are typically inspected for coil weight accuracy after processing by using weighing scales or load cells that are capable of accurately measuring the weight of the coil. The coil is placed on the scale or load cell, and the weight is compared to the target weight specified for that particular coil.

- Q: How do steel coils contribute to the aerospace industry?

- The aerospace industry benefits greatly from the utilization of steel coils. They serve multiple purposes in this field. Firstly, they are instrumental in the production of aircraft structures and components. Steel coils can be transformed into various forms, such as sheets or plates, which can then be shaped and welded to create essential parts of an aircraft, including wings, fuselage, and landing gear. The exceptional strength and durability of steel make it an optimal material for such critical components, guaranteeing the safety and dependability of the aircraft. Secondly, steel coils play a pivotal role in the manufacturing of jet engines. The extreme conditions and high temperatures that engines endure necessitate materials with outstanding heat resistance and mechanical properties. Steel coils, especially those made from alloys like stainless steel or nickel-based alloys, possess the requisite attributes to withstand the demanding environment within a jet engine. These coils can be processed into turbine blades, exhaust system components, and other engine parts, thereby enhancing the overall performance and efficiency of the aircraft. Furthermore, steel coils find utility in the construction of aerospace infrastructure and ground support equipment. Strong and durable materials are essential for ensuring the stability and longevity of structures like hangars, maintenance facilities, and launch pads. Steel coils are frequently fabricated into beams, columns, and other structural elements that form the foundation of these facilities, providing the necessary strength to withstand the various loads and vibrations associated with aerospace operations. In conclusion, the aerospace industry heavily relies on steel coils due to their indispensable qualities of strength, durability, and heat resistance. These coils contribute significantly to the manufacturing of aircraft structures, engine components, and aerospace infrastructure, thereby guaranteeing the safety, performance, and reliability of aircraft. This, in turn, facilitates the advancement of aviation technology and enables the exploration of new frontiers in aerospace.

- Q: what is the history of steel and how did they start making it, i need a link or an answer that is five paragraphs long. plus i need examples of subtitles about the history of steel. i am doing this for a science project and hope that someone can help me out.thanks

- There's wide history of steel, you can read different tutorials online to know more about it. Check wiki for detailed information.

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings for various purposes such as structural support, reinforcement, and as raw materials for manufacturing components like beams, columns, and steel plates. The coils are often transformed into different shapes and sizes through processes like cutting, bending, and welding to meet specific construction requirements. They provide strength, durability, and stability to building structures, making them a crucial element in the construction industry.

- Q: does he use a nylon guitar or steel?

- The correct term for what you are looking at is a classical guitar. Classical guitars always have nylon strings (steel strings will tear them apart). There is no such thing as a nylon guitar, and if there were, I don't think it would sound very good, although Mario Maccaferri did make some plastic ones that are quite collectible now. Steel guitar - as opposed to steel-string guitar which is what I think you mean - is the name of an entirely different instrument that doesn't look much like a guitar at all. There are also steel-bodied guitars which have a mechanical amplification system built in. However, normal classical and steel-string guitars are made of wood. A classical guitar usually has a slotted headstock with wide rollers, a wide uncambered fretboard, a 12-fret neck, an ornate soundhole rosette, no pickguard, a tied bridge with a straight saddle, and fan bracing. A steel-string guitar usually has a solid headstock or a slotted headstock with narrow rollers, a narrow cambered fretboard, a 14- or 12-fret neck, a simple rosette, a pickguard, a pin bridge with a slanted saddle, and X bracing.

- Q: haii, i have this guitar thats quite old and im not quite sure whether to put steel strings on it. there were very thin badly worn steel strings on it when i got it, so i think its an acoustic

- That's a very low-end Kay, maybe from the 60's or 70's. It has a weird mixture of steel-string and classical features that you often see in cheap imports from around that time, maybe because the factory didn't want to stock different parts for different lines. The tuners (one of which is missing) are made for steel strings. They will work with nylon but not well. The bridge is a generally classical type but appears to be bolted on and seems to have some compensation carved into the saddle, which indicates it may have been intended for steel strings. Probably it's ladder braced, which is not a great design for either type. It has a classical rosette and a steel-string pickguard. I am guessing the neck has steel reinforcement but unless there's a sticker there's no way to tell. Personally I'd put light or (preferably) extra-light steel strings on it. The short scale length will help keep the tension down. I'd keep an eye on the neck though. You could also try silk steel to be on the safe side, but the bass response will probably be lacking.

Send your message to us

PPGI/0.4mm-0.5mm Pre-Painted Galvanized Steel Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords