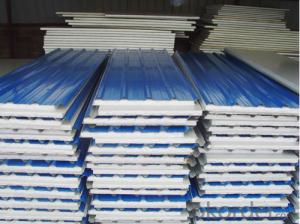

0.4mm/0.45mm/0.47mm/0.5mm Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

0.4mm/0.45mm/0.47mm/0.5mm Pre-Painted galvanized Steel Roofing Sheet PPGI

Painting: Polyester(PE) PVDF

Standard: ASTM, JIS,AISI, GB

Grade: SGCC.SPCC.DC51D,DC52D,DC53D

thickness: 0.2mm---1.0mm

Width: 914mm,1000mm, 1200mm, 1250mm, 1500mm or as your request

Zinc coating: 40-250g/m2

Color: Ral code or as the client request

Packing: wooden with the waterproof paper

Delivery: 4 weeks

MOQ: 5tons or negotiable

Applications

1) Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

2) Exterior applications such as: Wall cladding, facades, roofs and canopies, tunnels, column covers or renovations

3) Interior applications such as: Wall cladding, ceilings, bathrooms, kitchens and balconies

Brand Name | CNBM |

Product Name | PPGI / PPGL (PCM) |

Thickness of Base Metal | 0.2~0.8mm |

Painting material | Polyester(PE) PVDF epoxy |

Painting Thickness | 7~30μm |

Surface Protection | PE protective film |

Color | Ral code or as the client request |

Surface Treatment | Degreasing and chemical treatment |

Gloss | 5-105% |

Coating Hardness (pencil resistance) | ≥H |

Flexibility (T-bend) | ≤2T |

MEK resistance | More than 100 |

Supplying Status | Sheet: Width≤2000mm,Length≤5000mm |

Coil: Width≤2000mm,N.W≤5T,Inner Diameter: φ408mm φ505 φ508 | |

Application | Home appliance: Refrigerator shutter & side panels, Washer, Freezers, Air conditions, Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods Computer Panels , DVD/DVB panels, TV back panel etc. |

- Q: I understand that damascus sword steel was made by folding the strip of steele double , reheating, hammering, folding again and so forth hundreds of times. Was this the same or very nearly the same techmique the japs used making the sword blades the samari swords?(forgive the misspelling)

- Damascus: A folding technique where the steel is folded over itself many (generally up to sixteen) times, leading to hundreds or even thousands of layers (one fold = 2 layers, two folds = 4 layers, three folds = 8 layers, 16, 32, 64, 128, 256, 512, 1024, 2048, 4096, etc.). More folds than sixteen are pointless, as the layers would become thinner than one molecule - which is impossible. This method was developed to removed impurities from the steel (it also removes carbon, which is bad, but can be compensated for to some degree), but modern steel is so pure that Damascus folding is no longer needed. It is now used for aesthetic reasons; Damascus steel looks really good; you can see the layers in the blade. San Mai: Translates to three layers. Layers of softer, lower carbon steel (or iron) is forge welded to layers of harder, higher carbon steel. The lower carbon steel forms the core (and sometimes the sides and/or back), and the higher carbon steel forms the edge. The hard edge will hold its sharpness, the softer core provides shock absorption; making the sword harder to break. Unlike Damascus, San Mai is still very practical. San Mai folds should be invisible; if you can see a San Mai fold the forging was flawed and the blade should be discarded - you'll have to trust your seller that the blade is San Mai - you can't tell by looking. San Mai can be revealed by etching the blade with acid, such as lemon juice, but I don't recommend trying this unless you know what you're doing; you can permanently stain the blade. San Mai swords are more durable (and more expensive) than simple blades. They are more durable (and usually less expensive) than Damascus blades. A blade can be either San Mai or Damascus, or it can be both; Damascus steel which is then San Mai folded. Very cool, looks good and lasts long.

- Q: Can you reload spent casings if they are steel?

- you're not supposed to but if there's a will, there's a way. suppose it's the end of the world and you're just about to run out of ammunition, you can reload steel cases by drilling the primer pocket out to fit either a small boxer primer or large boxer primer. and drilling out a flash hole too. the cases must be from your gun and be able to chamber/extract without resizing. steel cases become brittle after a few uses, which become dangerous to reuse more than once. however if it's one of those situations you need ammo, it can be reloaded at low pressure a few dozen times, just give it a thorough inspection between reloading.

- Q: How are steel coils used in the production of aerospace components?

- Steel coils are used in the production of aerospace components as they provide the necessary strength and durability required for various applications such as structural parts, fasteners, and landing gear. These coils are typically processed and formed into specific shapes and sizes to meet the design requirements of the aerospace industry.

- Q: What are the different methods of slitting steel coils?

- There are several different methods of slitting steel coils, each with its own advantages and limitations. Some of the most common methods include: 1. Rotary Shear Slitting: This method involves using rotating knives to cut the steel coil into narrower strips. It is a versatile and efficient method that allows for high-speed production and precise slitting. Rotary shear slitting is commonly used for thinner gauge materials. 2. Looping Pit Slitting: In this method, the steel coil passes through a looping pit where it is guided and tensioned before being slit. It is suitable for thicker gauge materials and provides good edge quality. Looping pit slitting allows for higher coil speeds and can handle heavier coils. 3. Drag Slitting: This method involves dragging the steel coil over a stationary blade or set of blades to perform the slitting. It is particularly useful for materials that are difficult to slit, such as high-strength steels. Drag slitting provides excellent edge quality and is often used for precision slitting applications. 4. Crush Slitting: Crush slitting involves applying pressure to the steel coil to crush and separate it into narrower strips. It is a cost-effective method suitable for lower gauge materials. However, it may result in slightly rougher edge quality compared to other methods. 5. Laser Slitting: Laser slitting utilizes a focused laser beam to cut through the steel coil. It is a highly precise method that offers excellent edge quality and minimal distortion. Laser slitting is commonly used for high-value and specialty materials. Each method has its own advantages and is suitable for specific applications and material types. The choice of slitting method depends on factors such as material thickness, desired edge quality, production speed requirements, and budget.

- Q: How are steel coils used in the production of metal containers?

- Due to their versatility and strength, steel coils find wide application in the production of metal containers. Each stage of manufacturing metal containers relies heavily on steel coils. To begin with, steel coils serve as the primary raw material for metal container production. These coils consist of high-quality steel that is rolled into a continuous sheet, ensuring consistent thickness and durability. Subsequently, this sheet is cut into specific widths and lengths according to the container size requirements. Once the desired dimensions are achieved, various techniques are employed to shape the steel coils into container form. Roll forming, for example, is a commonly used method where the steel coil passes through a series of roll dies that gradually shape it into the desired container shape. This technique allows for the creation of containers in different sizes and designs, ranging from cans and drums to large industrial containers. After the initial forming process, the steel coils undergo further processing to enhance their strength and durability. Heat treatment is one such process where the coils are exposed to high temperatures to increase their hardness and resistance to wear and tear. Additionally, annealing and quenching methods may be employed to improve the steel's properties. Once the containers are formed and processed, additional fabrication steps, such as welding or sealing, are carried out to ensure their structural integrity. Steel coils are frequently utilized in these processes as they provide a robust and dependable material for creating sturdy seams and joints. Finally, metal containers receive various coatings or treatments to protect them from rust, corrosion, and other environmental factors. Steel coils can be coated with materials like paint, epoxy, or zinc to enhance their resistance to these elements, ultimately ensuring the longevity of the containers. In conclusion, steel coils play a crucial role in the production of metal containers. They serve as the primary raw material, aid in forming, processing, and finishing, and provide the necessary strength, durability, and versatility required for manufacturing reliable metal containers across a range of industries.

- Q: What are the common standards and specifications for steel coils?

- In the industry, there are various widely recognized and utilized standards and specifications for steel coils. Some notable ones include: 1. ASTM A36/A36M: This specification is concerned with carbon structural steel shapes, plates, and bars of structural quality. It is intended for use in constructions that involve riveting, bolting, or welding. 2. ASTM A572/A572M: This specification focuses on high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars. It is applicable for constructions involving bolting, riveting, or welding. 3. ASTM A653/A653M: This specification pertains to steel sheet that is zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) through the hot-dip process. 4. ASTM A1011/A1011M: This specification covers various types of steel sheet and strip in coils, such as hot-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high strength. 5. JIS G3302: This Japanese Industrial Standard specifies the requirements for hot-dip zinc-coated steel sheet, also known as galvanized steel sheet, and strip. 6. EN 10111: This European standard outlines the requirements for continuously hot-rolled low carbon steel sheet and strip that are suitable for cold forming. 7. ISO 3575: This International Organization for Standardization standard lays down the requirements for hot-dip zinc-coated and zinc-iron alloy-coated steel sheet and strip. These are just a few instances of the prevalent standards and specifications employed for steel coils. It is crucial to note that different industries and applications may have specific demands, thus consulting the relevant standards and specifications for the particular application is always advisable.

- Q: What website can I use to find a good picture that shows the atomic structure of a carbon steel?

- Carbon steel is a polycrystalline substance containing several compounds. Most of it is iron, but there are crystals of austenite and martensite present, plus other iron carbides. Each of these has a different atomic structure. The properties of the steel depend not so much on the atomic structures of the compounds, but more on the size and abundance of the crystals. The function of these crystals is to impede the movements of dislocations through the iron.

- Q: Ive been playing with my ping i3 graphite irons for 6 years now and some days i can hit it and some days i cant. Then i tried out my friends irons the other day and he had steel and i was hitting the ball anywhere i wanted it to go..Is that a fluke or is steel irons just better than shaft? I was thinking about trading my graphites for steel, is that a good idea??

- Graphite Or Steel Irons

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve inspecting the damage, assessing its severity, and determining if the coil is still safe to handle. If the damage is minor, it may be possible to repair or reinforce the coil. However, if the damage is extensive or compromises the structural integrity of the coil, it is recommended to contact a professional for further evaluation and potential disposal. Additionally, following proper safety protocols, such as wearing protective gear and using equipment suitable for handling heavy loads, is crucial when dealing with damaged steel coils.

- Q: How are steel coils used in the production of steel chains?

- Steel coils are used in the production of steel chains by being unwound and fed into a machine that shapes and forms the individual links of the chain. The steel coils provide the raw material needed to create the strong and durable chains, ensuring they have the necessary strength and integrity for various applications.

Send your message to us

0.4mm/0.45mm/0.47mm/0.5mm Pre-Painted Galvanized Steel Roofing Sheet PPGI

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords