FRP Roofing Panel B - High Quality FRP Roofing Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

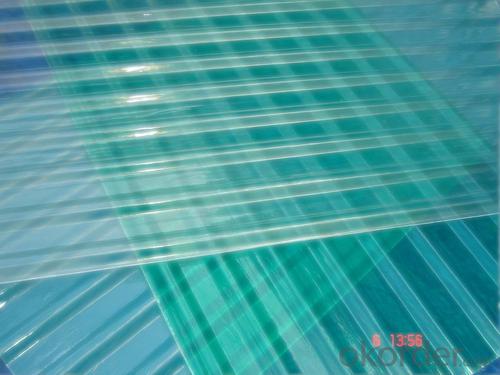

Specification of FRP Roofing Panel

Thickness:1.2mm

Color:sky blue, dark blue, clear, light green, dark green, opal, etc.

Ordinary Wave: 760-380

Length:No limit but with the consideration of transportation

Features of FRP Roofing Panel:

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable

for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

Packaging & Delivery

Packaging Detail: standard packing for export

Delivery Detail:3~7 days

- Q: Do FRP roofing panels expand or contract with temperature changes?

- Yes, FRP roofing panels do expand and contract with temperature changes.

- Q: Are FRP roofing panels resistant to bleach?

- FRP roofing panels are generally resistant to bleach. The material used in FRP panels, known as fiberglass reinforced plastic, is highly durable and resistant to a wide range of chemicals, including bleach. Bleach is commonly used as a cleaning agent, and FRP panels can withstand regular cleaning and exposure to bleach without significant damage or deterioration. However, it is important to note that prolonged or frequent exposure to bleach may cause some discoloration or fading of the panels over time.

- Q: Can FRP roofing panels be used for both pitched and low-slope roofs?

- FRP roofing panels are versatile and suitable for use on both pitched and low-slope roofs. However, it is imperative to take certain factors into account when using FRP panels on different roof slopes. For pitched roofs, it is necessary to install FRP panels with appropriate flashing and underlayment in order to create a durable and watertight roofing system. The panels should be securely fastened to the roof structure, and the slope of the roof must not exceed the specifications recommended by the manufacturer. Additionally, ensuring proper drainage on pitched roofs is crucial to avoid water accumulation and potential damage to the panels. When it comes to low-slope roofs, FRP panels can also be utilized effectively. However, it is important to consider the roof pitch and the specific requirements for low-slope applications. Additional support or reinforcement may be necessary to prevent sagging or water pooling on the roof surface. Proper installation techniques, including the use of suitable sealants and fasteners, are essential for maintaining the integrity of the roofing system. In conclusion, FRP roofing panels are suitable for both pitched and low-slope roofs. However, it is important to adhere to the guidelines provided by the manufacturer, consider the specific requirements of the roof slope, and ensure proper installation techniques to establish a durable and watertight roofing system. It is advisable to consult with a roofing professional or the manufacturer to determine the suitability of FRP panels for a particular roof slope and to ensure proper installation and maintenance.

- Q: Can FRP roofing panels be used in areas with heavy snowfall?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in areas with heavy snowfall. These panels are known for their durability and strength, making them suitable for withstanding heavy snow loads. However, it is important to ensure that the panels are installed and supported properly to handle the weight of the snow. Additionally, periodic maintenance and clearing of the panels may be required to prevent excessive snow accumulation.

- Q: Are FRP roofing panels fire-resistant?

- Indeed, FRP (Fiberglass Reinforced Plastic) roofing panels possess fire-resistant qualities. Their composition comprises a blend of fortified fiberglass and plastic resin, endowing them with superb resistance against fire. These panels boast a substantial ignition temperature and do not emit any noxious or detrimental fumes when subjected to flames. Furthermore, FRP roofing panels have the ability to self-extinguish, ceasing to burn once the fire's origin is eliminated. Consequently, they serve as a secure option for roofing purposes, especially in regions prioritizing fire safety.

- Q: Can FRP roofing panels be installed on unconventional roof shapes or designs?

- FRP roofing panels have the capability to be installed on atypical roof shapes or designs. These panels possess flexibility and can be effortlessly shaped to conform to different roof shapes, such as curved or sloped surfaces. Their lightweight quality also renders them appropriate for unconventional roof designs. Moreover, FRP panels can be tailored and adjusted on-site to accommodate specific roof shapes or designs, offering a versatile option for a diverse range of roofing needs. Nevertheless, it is advisable to seek guidance from a professional roofing contractor or manufacturer in order to guarantee correct installation and adherence to building codes and regulations.

- Q: What is an FRP roofing panel?

- An alternative to the traditional roofing materials is the FRP roofing panel, also known as a fiberglass reinforced panel. It is composed of a combination of fiberglass and polyester resin. These panels are widely used in industrial and commercial buildings due to their durability, strength, and ability to withstand different environmental conditions. The lightweight nature of FRP roofing panels makes them easy to install, transport, and handle. They come in various sizes, thicknesses, and colors, providing flexibility in design and aesthetics. The manufacturing process of these panels involves pultrusion, where fiberglass strands are pulled through a resin bath to ensure a consistent and uniform distribution of the resin. One of the main advantages of FRP roofing panels is their remarkable strength-to-weight ratio. They possess exceptional strength and can endure heavy loads, high winds, and impacts without cracking or breaking. This quality makes them ideal for roofs in areas prone to severe weather conditions or where structural weight is a concern. Moreover, FRP roofing panels exhibit high resistance to corrosion, chemicals, and UV radiation. This makes them a long-lasting and low-maintenance roofing option as they do not rust, rot, or deteriorate over time. Consequently, the need for frequent repairs or replacements is significantly reduced. Additionally, these panels are fire-resistant, enhancing the safety of the building and its occupants. Furthermore, FRP roofing panels provide excellent thermal and sound insulation properties. They help maintain a comfortable indoor temperature by reducing heat transfer, subsequently reducing energy consumption and utility costs. The insulation also aids in minimizing noise transmission, creating a quieter and more peaceful environment inside the building. In conclusion, the FRP roofing panel is a versatile roofing material that offers durability, lightweight construction, and insulation properties. Made from fiberglass and polyester resin, it possesses exceptional strength, resistance to environmental factors, and contributes to energy efficiency. Hence, it is a popular choice for industrial and commercial buildings.

- Q: Can FRP roofing panels reduce energy costs?

- Yes, FRP roofing panels can help reduce energy costs. FRP (Fiberglass Reinforced Panels) roofing is known for its excellent insulation properties. These panels have a high R-value, which measures the thermal resistance of a material. This means that FRP roofing panels can prevent heat transfer from the outside to the inside and vice versa, helping to maintain a stable and comfortable temperature inside the building. By reducing heat transfer, FRP roofing panels can significantly decrease the need for heating and cooling systems, therefore reducing energy consumption and costs associated with them. In hot climates, FRP roofing panels can reflect sunlight and prevent excessive heat from entering the building, resulting in lower cooling requirements. In cold climates, the insulation properties of these panels can help retain heat generated by heating systems, reducing the need for continuous heating. Additionally, FRP roofing panels are highly durable and long-lasting. They are resistant to weathering and UV radiation, which can cause degradation and reduce their energy-saving properties over time. This durability means that these panels will continue to provide insulation and save energy costs for many years, making them a cost-effective choice in the long run. Overall, FRP roofing panels can play a significant role in reducing energy costs by providing excellent insulation and minimizing the need for heating and cooling systems.

- Q: Are FRP roofing panels resistant to UV rays?

- Yes, FRP roofing panels are generally resistant to UV rays. The panels are specifically designed with UV inhibitors that protect them from the damaging effects of sunlight, allowing them to maintain their structural integrity and aesthetic appeal over time.

- Q: Are FRP roofing panels resistant to warping or sagging due to heat?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are known for their high resistance to warping or sagging due to heat. The composition of FRP panels includes fiberglass reinforcement, which provides exceptional strength and stability even under high temperatures. This reinforcement helps prevent the panels from warping or sagging, ensuring their long-term durability and performance. In addition to the fiberglass reinforcement, FRP panels are also designed to have low thermal expansion properties. This means that they have minimal expansion or contraction with temperature changes, reducing the chances of warping or sagging. The panels are engineered to withstand the heat and maintain their shape and structural integrity, making them a reliable choice for roofing applications. It is worth noting that while FRP panels are resistant to warping or sagging due to heat, proper installation and maintenance are crucial to ensure their longevity. Following manufacturer guidelines and regularly inspecting and maintaining the roof will help maximize the performance and lifespan of the FRP roofing panels.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 300,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Roofing Panel B - High Quality FRP Roofing Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100Pcs m.t.

- Supply Capability:

- 1000Pcs m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords