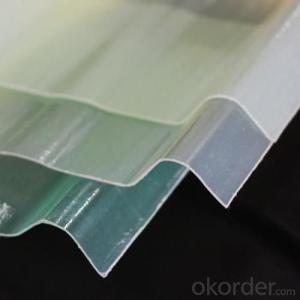

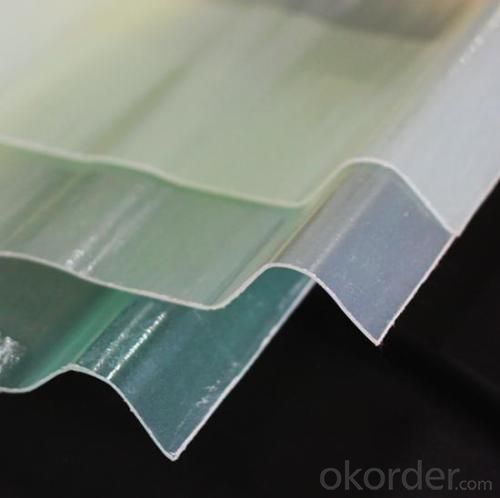

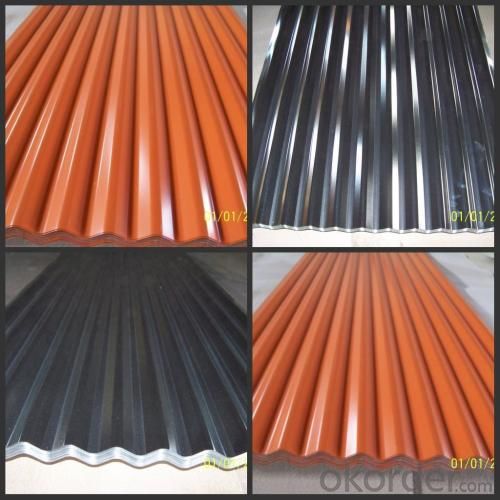

Translucent Fiberglass Roofing Sheets, Corrugated Fiberglass Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

PICTURES

- Q: Are FRP roofing panels suitable for retail buildings?

- Retail buildings can benefit from the use of FRP roofing panels. These panels offer several advantages that make them a suitable choice. Firstly, FRP roofing panels are lightweight and easy to install. This reduces the load on the building's structure, which is particularly useful for retail buildings with large roof areas. Secondly, FRP panels are durable and long-lasting. They resist corrosion, UV radiation, and extreme weather conditions, ensuring the aesthetics and structural integrity of the retail building. Additionally, FRP panels provide excellent insulation. They regulate the temperature inside the retail building, reducing energy consumption and lowering heating and cooling costs. Furthermore, FRP panels come in various colors, finishes, and profiles, allowing architects and designers to create a visually appealing and customized roof that aligns with the retail space's brand image and design. In conclusion, FRP roofing panels are a suitable choice for retail buildings. Their lightweight nature, durability, insulation properties, and aesthetic options make them beneficial for cost-effectiveness, durability, and energy efficiency.

- Q: Can FRP roofing panels be used in shopping malls or retail centers?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in shopping malls or retail centers. FRP roofing panels are known for their durability, versatility, and resistance to corrosion, making them suitable for various applications including commercial buildings. They are lightweight, making installation easier and more cost-effective. Additionally, FRP roofing panels are available in a wide range of colors and finishes, allowing them to seamlessly integrate with the design and aesthetic of shopping malls or retail centers. The panels also provide excellent natural light transmission, reducing the need for artificial lighting during the day and potentially saving on energy costs. Overall, FRP roofing panels are a viable choice for shopping malls or retail centers due to their durability, versatility, and aesthetic appeal.

- Q: Can FRP roofing panels be used for universities?

- Yes, FRP roofing panels can be used for universities. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and resistant to corrosion, making them suitable for various applications, including universities. They provide excellent weather protection, low maintenance requirements, and can be customized to fit different architectural styles. Additionally, FRP panels can offer energy efficiency benefits by reducing heat transfer, enhancing insulation, and allowing the integration of natural lighting.

- Q: Can FRP roofing panels be used for outdoor structures?

- Outdoor structures can indeed utilize FRP (Fiber Reinforced Plastic) roofing panels. Renowned for their sturdiness, robustness, and ability to withstand diverse weather elements like UV rays, rain, and wind, FRP roofing panels are specifically engineered to endure challenging outdoor conditions, ensuring exceptional safeguarding for various structures. They are frequently employed in outdoor settings, including patios, pergolas, carports, sheds, and agricultural buildings. Apart from their exceptional resistance to weather, FRP roofing panels possess the advantages of being lightweight, easy to install, and having a long lifespan. All in all, FRP roofing panels present a dependable and pragmatic choice for outdoor structures.

- Q: Do FRP roofing panels require any specific type of sealant or adhesive for installation?

- Yes, FRP roofing panels typically require a specific type of sealant or adhesive for proper installation. It is important to use a sealant or adhesive that is compatible with FRP materials to ensure a strong bond and long-lasting performance.

- Q: How do FRP roofing panels affect the acoustics of a building?

- FRP (Fiberglass Reinforced Plastic) roofing panels can have a positive impact on the acoustics of a building. These panels are known for their sound-absorbing properties, as they can effectively reduce noise levels by absorbing and dampening sound waves. By installing FRP roofing panels, the overall acoustic environment of a building can be improved, minimizing echoes, reverberation, and overall noise pollution.

- Q: Are FRP roofing panels suitable for architectural accents?

- Yes, FRP roofing panels are suitable for architectural accents. They offer a versatile and aesthetically pleasing option for adding unique design elements to buildings. Additionally, FRP panels are lightweight, durable, and can be easily customized to fit various architectural styles, making them an excellent choice for enhancing the visual appeal of any structure.

- Q: Are FRP roofing panels compatible with different insulation materials?

- Indeed, various insulation materials can be used in conjunction with FRP roofing panels. FRP, an abbreviation for fiberglass reinforced plastic, is an exceedingly adaptable and long-lasting substance. It harmonizes well with a diverse array of insulation materials, including polyurethane foam, polystyrene, mineral wool, and more. This compatibility grants an extensive selection of choices for attaining thermal insulation and energy efficiency within structures. To guarantee appropriate installation and compatibility with FRP roofing panels, it is crucial to take into account the specific prerequisites and suggestions of the insulation manufacturer, as well as seek guidance from roofing professionals.

- Q: Do FRP roofing panels have a warranty?

- Yes, FRP roofing panels typically come with a warranty. The specific duration and terms of the warranty may vary depending on the manufacturer and the specific panel model. It is advisable to check with the manufacturer or supplier for detailed information regarding the warranty coverage and any conditions or limitations that may apply.

- Q: Are FRP roofing panels suitable for regions with heavy snowfall?

- Indeed, FRP (Fiberglass Reinforced Plastic) roofing panels are appropriate for areas experiencing heavy snowfall. Renowned for their robustness and resilience, FRP panels exhibit exceptional resistance against extreme weather conditions, including the burden of heavy snow loads. Their remarkable load-bearing capacity enables them to endure the weight of accumulated snow without compromising their structural integrity. Moreover, FRP roofing panels possess a sleek surface that averts the adherence and accumulation of snow on the roof. This characteristic effectively reduces the likelihood of roof damage caused by excessive snow load. Additionally, FRP panels are engineered with a high resistance to moisture, ensuring their resistance to rotting or deterioration when exposed to snow or melting ice. Furthermore, FRP roofing panels offer outstanding insulation properties, which contribute to minimizing heat loss and reducing energy consumption during the winter season. This advantage proves especially advantageous in regions with heavy snowfall as it assists in maintaining a comfortable and energy-efficient indoor environment. In conclusion, FRP roofing panels undeniably prove suitable for regions encountering heavy snowfall, owing to their strength, durability, moisture resistance, and excellent insulation properties. These panels offer a dependable and long-lasting roofing solution that effortlessly withstands the challenges posed by heavy snow loads.

Send your message to us

Translucent Fiberglass Roofing Sheets, Corrugated Fiberglass Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords