FRP Roofing Panel - FRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATIONS

| Items | Data |

| Tensile Strength | 122.8Mpa |

| Tensile Modulus | 8610Mpa |

| Flexural Strength | 219.9mPA |

| Flexural Modulus | 8210Mpa |

| Barcol Hardness | 47 |

| Izod Impact | 80.4kj/m2 |

| Thermal Expansivity | 2.4X10-5 °C-1 |

| Distortion Termperature | >230°C |

| Water Absorption | 0.16%/24hrs@25°C |

| Gravity | 1.5g/cm3-1.9g/cm3 |

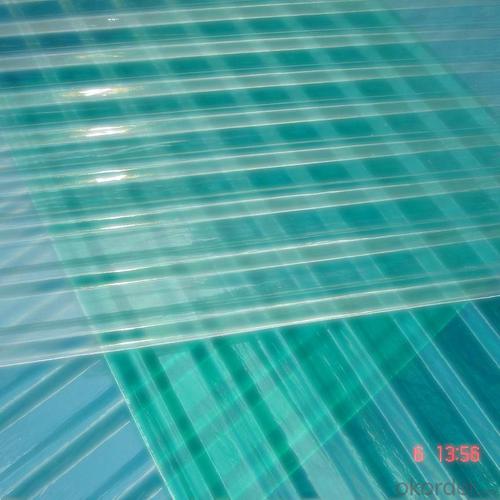

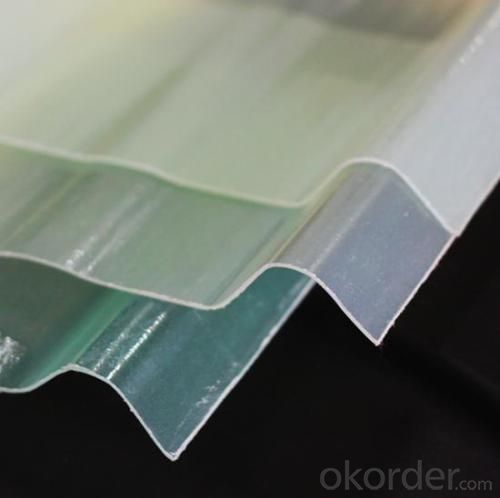

PICTURES

- Q: Can FRP roofing panels be recycled?

- Yes, FRP roofing panels can be recycled. FRP stands for Fiberglass Reinforced Plastic, which is a composite material made of glass fibers and resin. It is commonly used in roofing due to its durability and resistance to various weather conditions. When these panels reach the end of their life cycle, they can be recycled by removing the fiberglass fibers from the resin matrix. The fibers can then be reused in various applications, while the resin can be processed and used as a fuel source or for other purposes. Recycling FRP roofing panels helps reduce waste and supports sustainable practices in construction.

- Q: How are FRP roofing panels installed?

- FRP (Fiberglass Reinforced Plastic) roofing panels are typically installed in a sequence of steps that ensure a secure and weatherproof installation. Here is a general overview of how FRP roofing panels are installed: 1. Planning and Preparation: Before installation, it is important to thoroughly plan the roofing project. This includes measuring the roof area, ensuring proper flashing and trim materials are available, and acquiring all necessary tools and safety equipment. 2. Safety Measures: Safety should always be a top priority during the installation process. Installers should wear appropriate personal protective equipment (PPE) such as gloves, goggles, and non-slip shoes. Additionally, proper fall protection systems should be in place if working at heights. 3. Roof Surface Preparation: The existing roof surface should be cleaned and cleared of any debris or loose materials. It is important to ensure that the roof is structurally sound and capable of supporting the weight of the FRP panels. 4. Flashing and Trim Installation: Flashing and trim materials are essential for preventing water intrusion and providing a finished appearance. These components are typically installed first, using appropriate fasteners, adhesives, or sealants as recommended by the manufacturer. 5. Panel Layout and Measurement: Before installing the FRP panels, it is important to plan the layout and measure the roof area accurately. This helps to determine the number and size of panels required, ensuring a proper fit and minimizing waste. 6. Panel Installation: FRP panels are installed by positioning them on the roof surface and aligning them according to the predetermined layout. The panels are typically secured using screws or nails, with spacing and fastening methods specified by the manufacturer. It is important to follow the recommended installation guidelines to ensure proper panel alignment, sufficient fastening, and structural integrity. 7. Panel Sealing and Waterproofing: To ensure a watertight roof, it is important to seal the joints and edges of the FRP panels. This is typically done using sealants or adhesives recommended by the manufacturer. Proper sealing prevents water infiltration and protects the underlying roof structure. 8. Finishing Touches: Once the panels are securely installed and sealed, any remaining trim or flashing components are added to complete the installation. These finishing touches provide a clean and professional appearance while enhancing the overall durability of the FRP roofing system. It is important to note that the specific installation process may vary depending on the manufacturer's instructions, the type of FRP panels used, and the unique characteristics of the roof. Therefore, it is recommended to consult the manufacturer's installation guidelines for detailed instructions and best practices. Additionally, it is advisable to hire a professional roofing contractor with experience in FRP roofing installations for a safe and reliable installation process.

- Q: Are FRP roofing panels prone to discoloration over time?

- Discoloration is unlikely to occur over time with FRP (Fiberglass Reinforced Plastic) roofing panels. These panels have a reputation for their exceptional resistance to UV rays, preventing fading or yellowing that may be observed with alternative materials. However, it should be noted that the degree of discoloration is influenced by the quality of the FRP panels and the surrounding environment during installation. If the panels are of inferior quality or exposed to severe weather conditions, such as extreme heat or excessive moisture, there is a possibility of some discoloration occurring gradually. To minimize the chance of discoloration, it is advisable to opt for high-quality FRP roofing panels and diligently maintain and clean them on a regular basis.

- Q: Are FRP roofing panels available in different profiles or styles?

- Yes, FRP roofing panels are available in various profiles and styles to suit different architectural and design needs.

- Q: Can FRP roofing panels be installed over purlins or directly on the roof deck?

- FRP (Fiberglass Reinforced Plastic) roofing panels can be installed over purlins or directly on the roof deck, depending on the specific requirements of the project. When installing FRP panels over purlins, it is important to ensure that the purlins are properly spaced and securely fastened to provide adequate support for the panels. The spacing of the purlins should be determined based on the manufacturer's recommendations and the local building codes. If the roof deck is in good condition and structurally sound, FRP panels can also be installed directly on the roof deck. However, it is important to ensure that the deck is clean and free of any debris or loose materials before installation. Additionally, proper sealing and flashing should be used to prevent water penetration and ensure a watertight installation. Ultimately, the method of installation will depend on the specific requirements and conditions of the project. It is always recommended to consult with a professional contractor or the manufacturer of the FRP panels to determine the best installation method for your specific application.

- Q: Can FRP roofing panels be used for retail buildings?

- Yes, FRP (Fiberglass Reinforced Panels) roofing panels can be used for retail buildings. FRP panels are a popular choice for commercial and industrial buildings due to their durability, lightweight nature, and cost-effectiveness. They are resistant to corrosion, weathering, and UV radiation, making them ideal for retail buildings that require long-lasting and low-maintenance roofing solutions. Additionally, FRP panels offer excellent insulation properties, which can help regulate temperature and reduce energy costs for retail buildings. They are available in a variety of colors, styles, and profiles, allowing for customization to match the aesthetic requirements of the retail space. Furthermore, FRP panels are easy to install and require minimal maintenance throughout their lifespan, making them convenient for retail building owners and reducing operational costs. They can also be easily replaced if damaged, ensuring that the retail building remains functional and visually appealing. Overall, FRP roofing panels are a suitable choice for retail buildings due to their durability, versatility, energy efficiency, and cost-effectiveness.

- Q: Are FRP roofing panels compatible with roof vents or exhaust fans?

- FRP roofing panels, when it comes to compatibility with roof vents and exhaust fans, certainly get the job done. Their versatility allows for effortless installation alongside various accessories, such as roof vents and exhaust fans. With their lightweight and durable composition, FRP panels effortlessly accommodate these ventilation systems without compromising the roof's structural integrity. Furthermore, their resistance to corrosion, moisture, and UV rays make them the perfect choice for areas necessitating proper ventilation through roof vents and exhaust fans.

- Q: Can FRP roofing panels be used for walkways or catwalks?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for walkways or catwalks. FRP panels are lightweight, durable, and have excellent strength properties, making them suitable for various industrial and commercial applications, including walkways and catwalks. These panels are resistant to corrosion, chemicals, and UV rays, making them ideal for outdoor use. Additionally, FRP panels can be customized to fit specific design requirements, making them versatile for different walkway and catwalk installations. Overall, FRP roofing panels are a cost-effective and reliable option for creating safe and functional walkways and catwalks.

- Q: Are FRP roofing panels suitable for ice and snow regions?

- Considering ice and snow regions, FRP roofing panels possess specific qualities that render them appropriate. Nonetheless, it is important to take certain factors into account. Durability stands out as one of the key advantages of FRP roofing panels in cold climates. They exhibit remarkable resistance to impact, cracking, and splitting, which is critical when confronted with heavy snowfall and ice accumulation. Moreover, FRP panels do not absorb moisture, preventing them from becoming brittle or warping when exposed to freezing temperatures. Additionally, they possess high corrosion resistance, avoiding rot or rust, making them optimal for regions with severe winter weather. Another element to consider is the thermal conductivity of FRP roofing panels. They boast low thermal conductivity, implying that heat transfer is not easily facilitated. This attribute proves advantageous in ice and snow regions as it helps thwart the formation of ice dams on the roof. Ice dams occur when heat from the interior of the building escapes through the roof, causing snow to melt and refreeze at the roof edges. FRP panels assist in maintaining a consistent temperature on the roof surface, minimizing the risk of ice dams. Nevertheless, it is crucial to acknowledge that FRP roofing panels are not completely immune to ice and snow-related issues. Similar to other roofing materials, they can accumulate snow and ice, necessitating periodic removal to prevent excessive roof weight. Furthermore, proper installation and insulation are vital to ensure optimal performance of the panels in cold climates. Sufficient ventilation and insulation in the attic space can aid in preventing the formation of ice dams and reducing heat loss. In conclusion, FRP roofing panels can be a suitable option for ice and snow regions due to their durability, resistance to moisture and corrosion, as well as their low thermal conductivity. However, consulting a professional and ensuring proper installation and maintenance are essential to maximize their effectiveness in these specific climatic conditions.

- Q: Do FRP roofing panels have any specific load-bearing capacity?

- FRP roofing panels possess a distinct load-bearing capacity. Several factors influence the load-bearing capacity of FRP roofing panels, including the material's thickness and composition, the panels' design and installation, and the intended application and purpose of the panels. FRP roofing panels are engineered to endure a specific amount of weight or load without undergoing deformation or structural failure. Manufacturers or relevant industry standards typically determine the load-bearing capacity of FRP roofing panels through comprehensive testing and evaluation. These assessments evaluate the panels' ability to resist various types of loads, encompassing static loads like the panels' own weight or the accumulation of snow or ice, as well as dynamic loads like wind or seismic forces. It is worth noting that the load-bearing capacity of FRP roofing panels can differ based on the specific model or brand. Hence, it is crucial to refer to the manufacturer's technical specifications or guidelines to ascertain the precise load-bearing capacity of the panels employed in a particular project. Moreover, it is advisable to enlist the expertise of a certified structural engineer or roofing professional who can evaluate the project's specific requirements and guarantee that the load-bearing capacity of the FRP roofing panels is suitable for the intended application. By taking these precautions, the safety and durability of the roofing system can be ensured.

Send your message to us

FRP Roofing Panel - FRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords